Site high-speed dynamic balance method for large steam turbine generator unit shafting

A turbogenerator set, high-speed dynamic balancing technology, applied in the field of high-speed dynamic balancing, can solve problems such as aggravation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

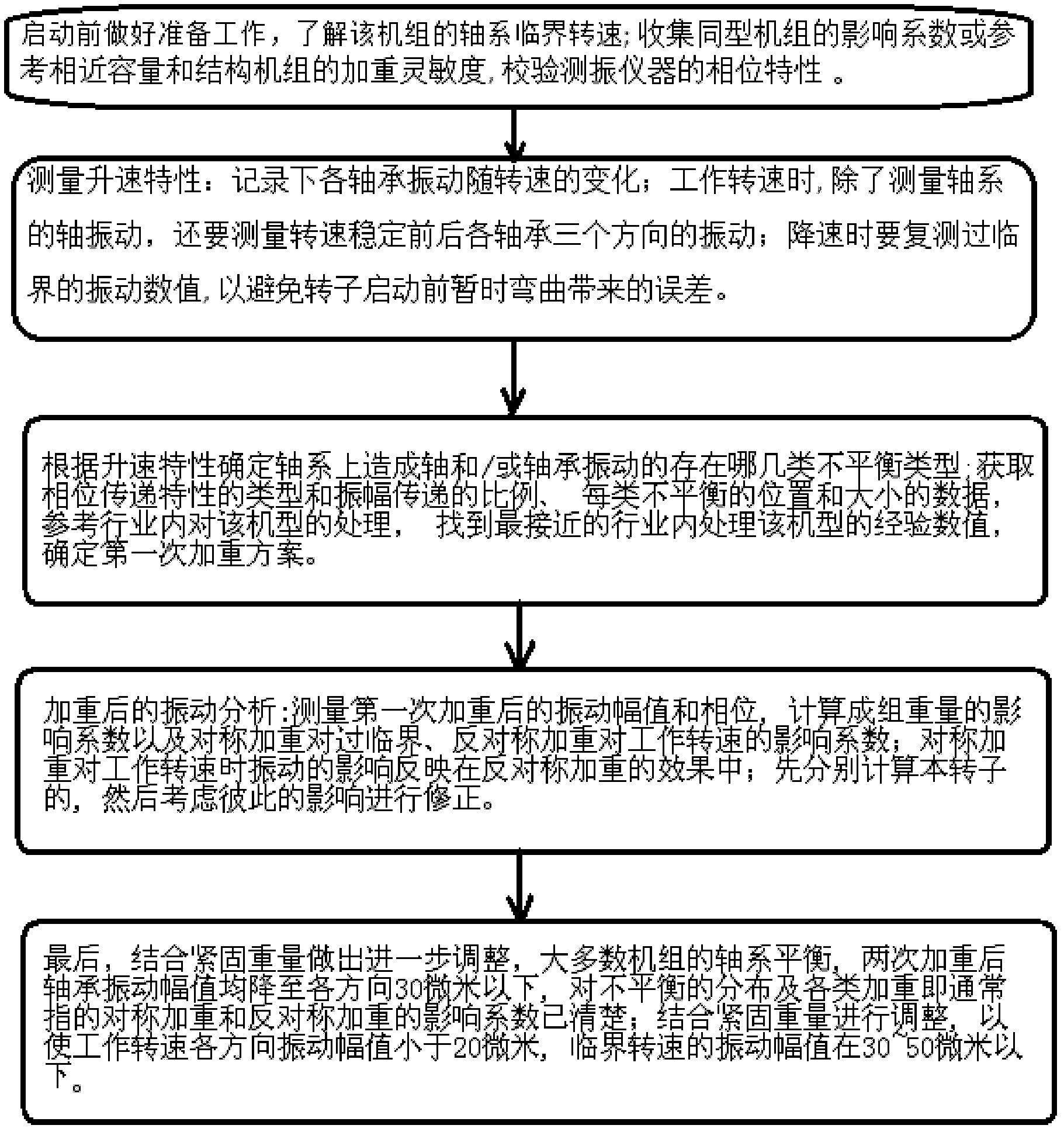

[0049] figure 1 , Figure 2a, Figure 2b, image 3 In production, an on-site high-speed dynamic balancing method for the shafting of a large turbogenerator set includes the following steps:

[0050] 1) Make preparations for the start-up of the shafting of large turbogenerator sets;

[0051] 2) Start the shafting of the large turbo-generator set, measure the speed-up characteristics, and record the amplitude and phase of the shaft vibration of the shaft and the variation of the vibration amplitude and phase of each bearing with the speed;

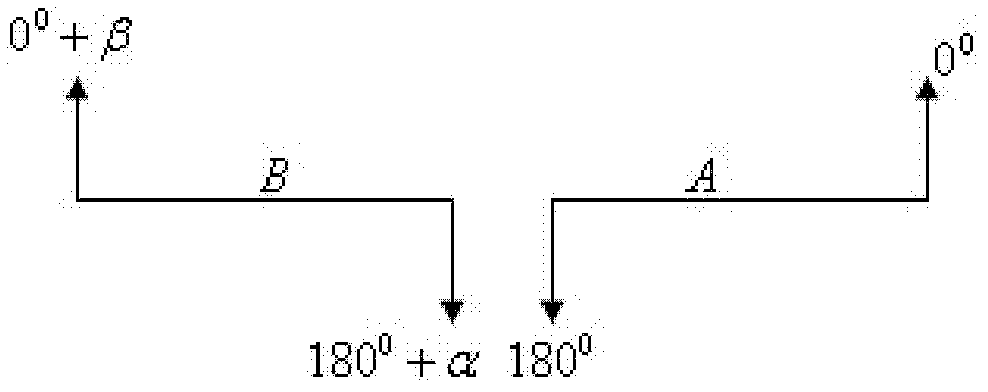

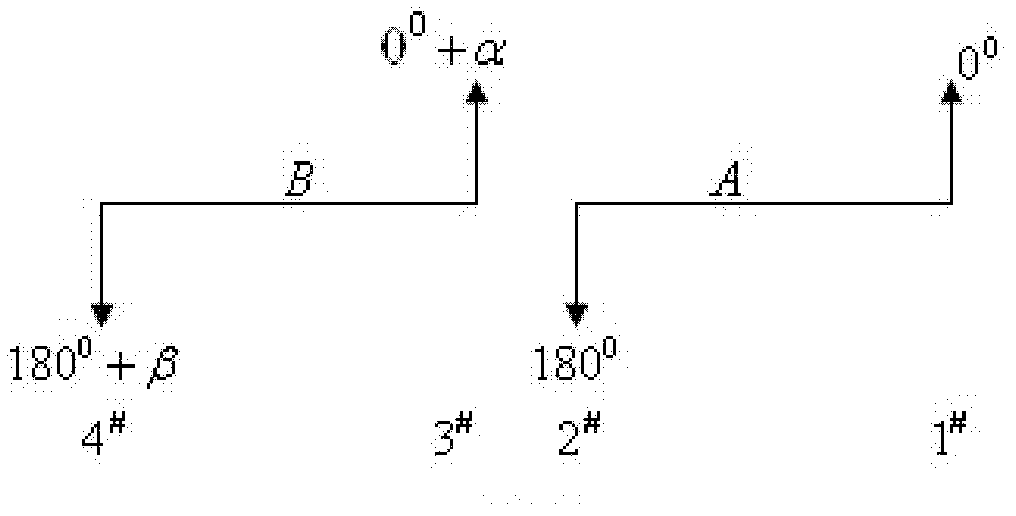

[0052] 3) Determine which types of unbalances exist on the shafting according to the characteristics of the speed-up, namely: whether there are unbalances caused by the first-order vibration shape, the second-order vibration shape and the third-order vibration shape, as well as the unbalance of the extension end, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com