Framework-type support component for wind tunnel test model

A technology for supporting members and wind tunnel testing, which is used in aerodynamic testing, testing of machine/structural components, measuring devices, etc., and can solve problems such as deficiencies, the influence of supporting members on wind tunnel airflow, and the rigidity of large supporting members. Achieve the effect of reducing self-weight, reducing deformation, and improving support stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

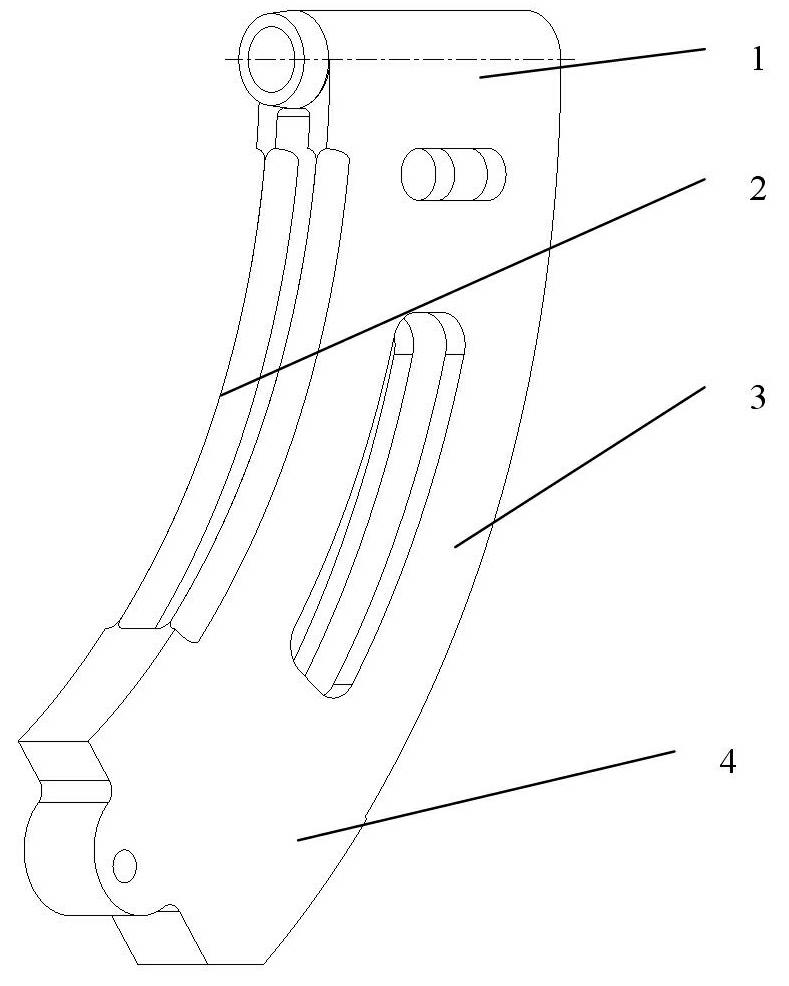

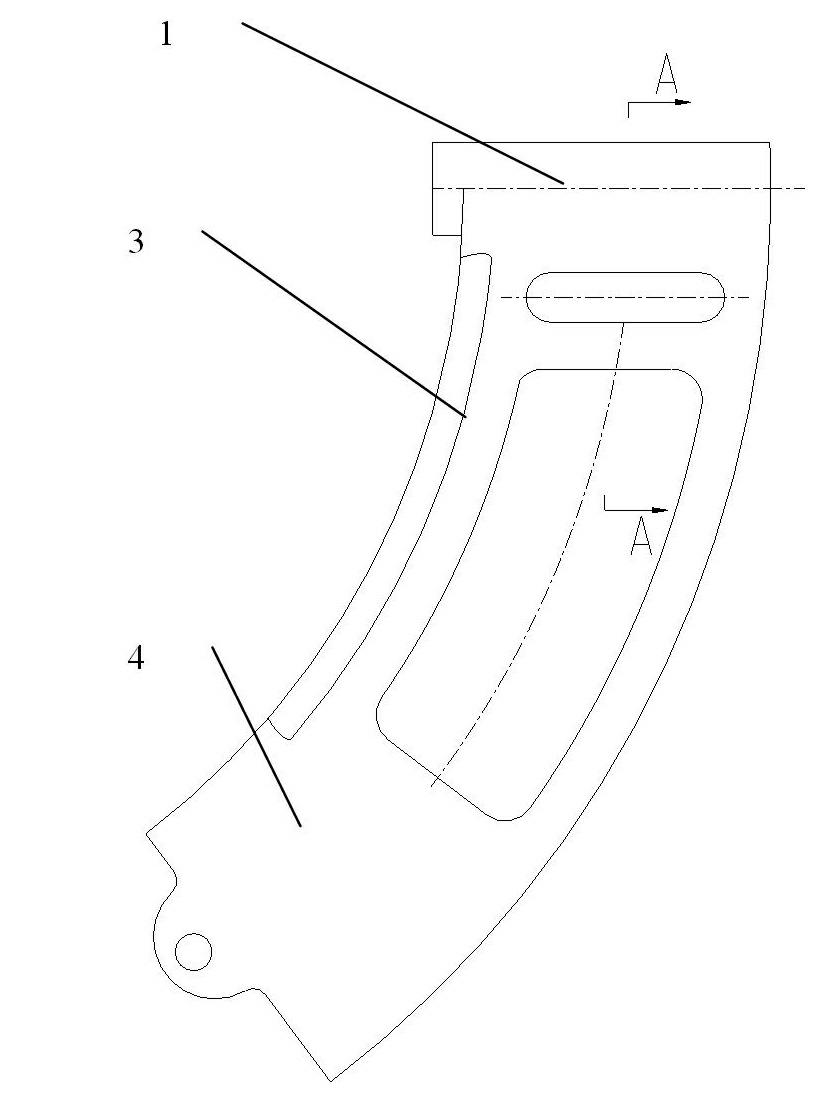

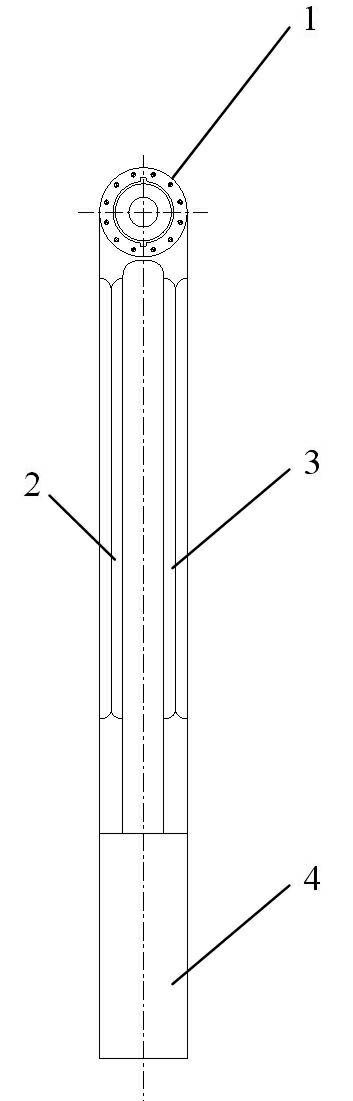

[0020] like figure 1 , figure 2 , image 3 , Figure 4 As shown, the skeleton-type wind tunnel test model support member of the present invention is composed of a middle bracket 1, a left support plate 2, a right support plate 3, and a lower connecting seat 4. Angle type, under the action of the driving mechanism, the support member can make up and down pitching motion and horizontal side sliding direction rotation. Two upper discharge holes are arranged symmetrically on the left and right sides of the middle support 1; the left support plate 2 and the right support plate 3 are respectively connected with the middle support 1, and two lower discharge holes are symmetrically arranged on the left support plate 2 and the right support plate 3; The lower connection base 4 connects the left support plate 2 and the right support plate 3 as a whole, and the lower connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com