Cutting plotter

A cutting and plotting machine and cutting processing technology, which is applied in the field of cutting and plotting machines, can solve the problems of inability to process medium cutting, inability to move the carriage straightly, deterioration of the quality of the processed medium, etc., and achieve the effect of preventing quality deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

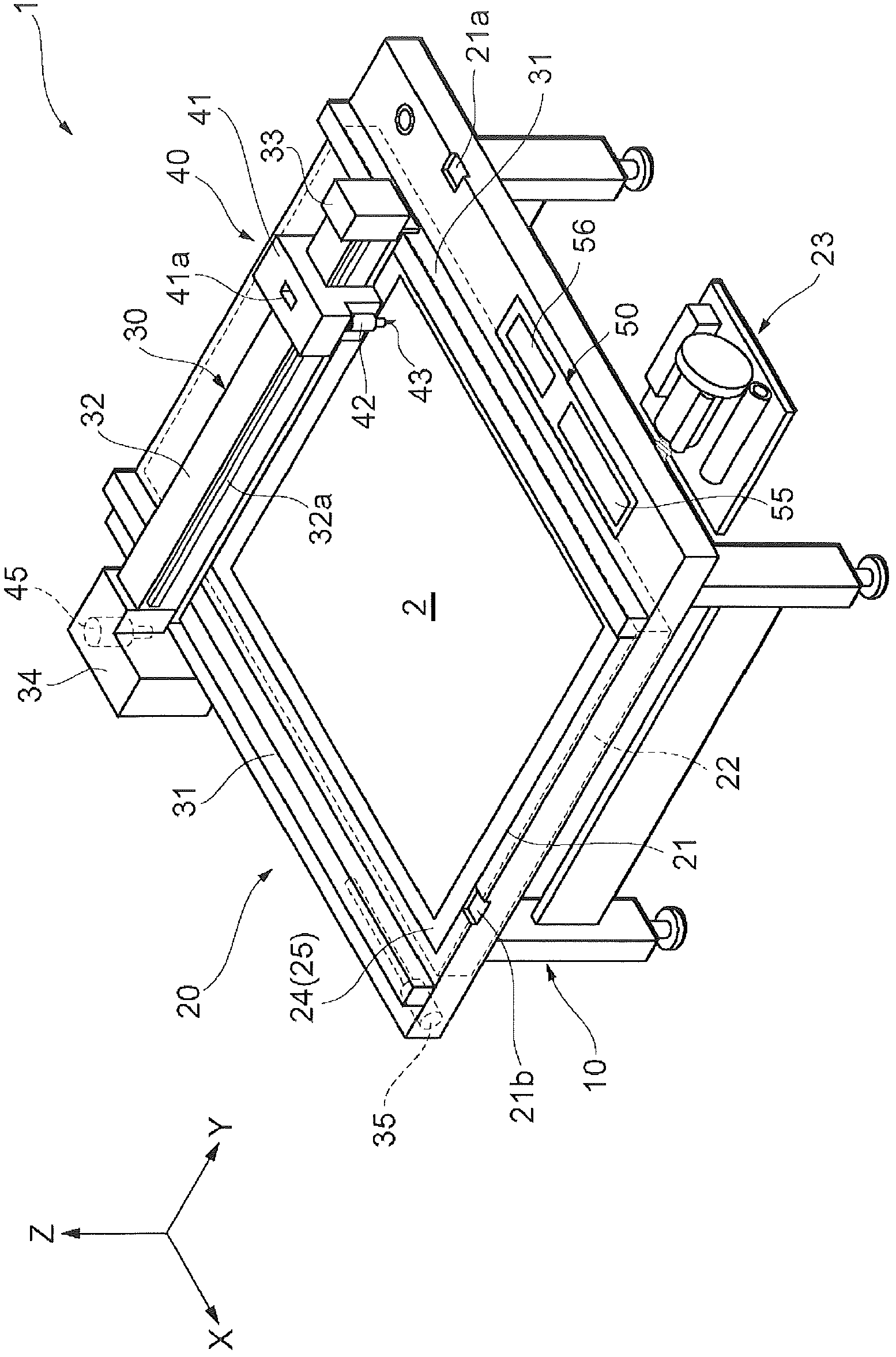

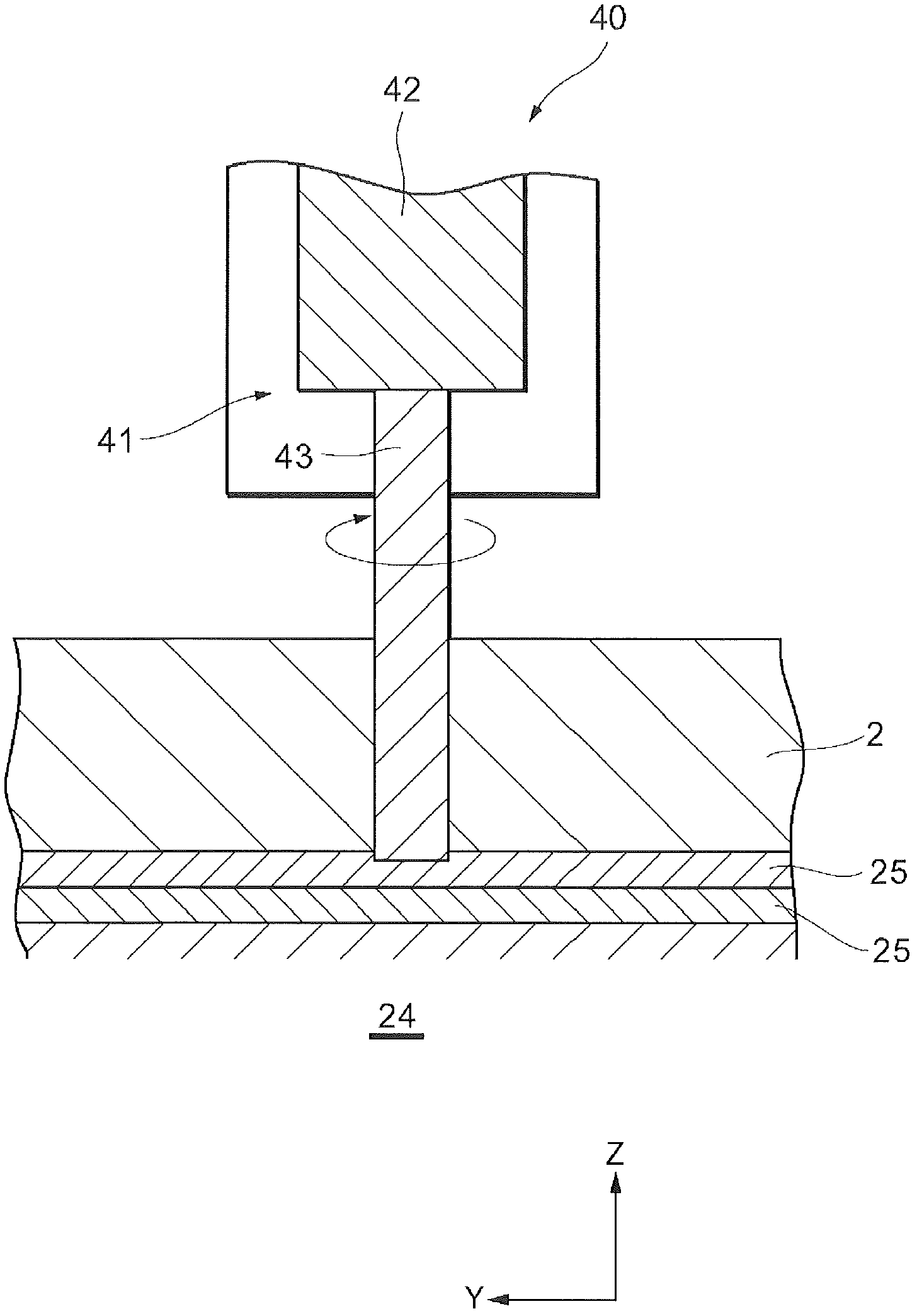

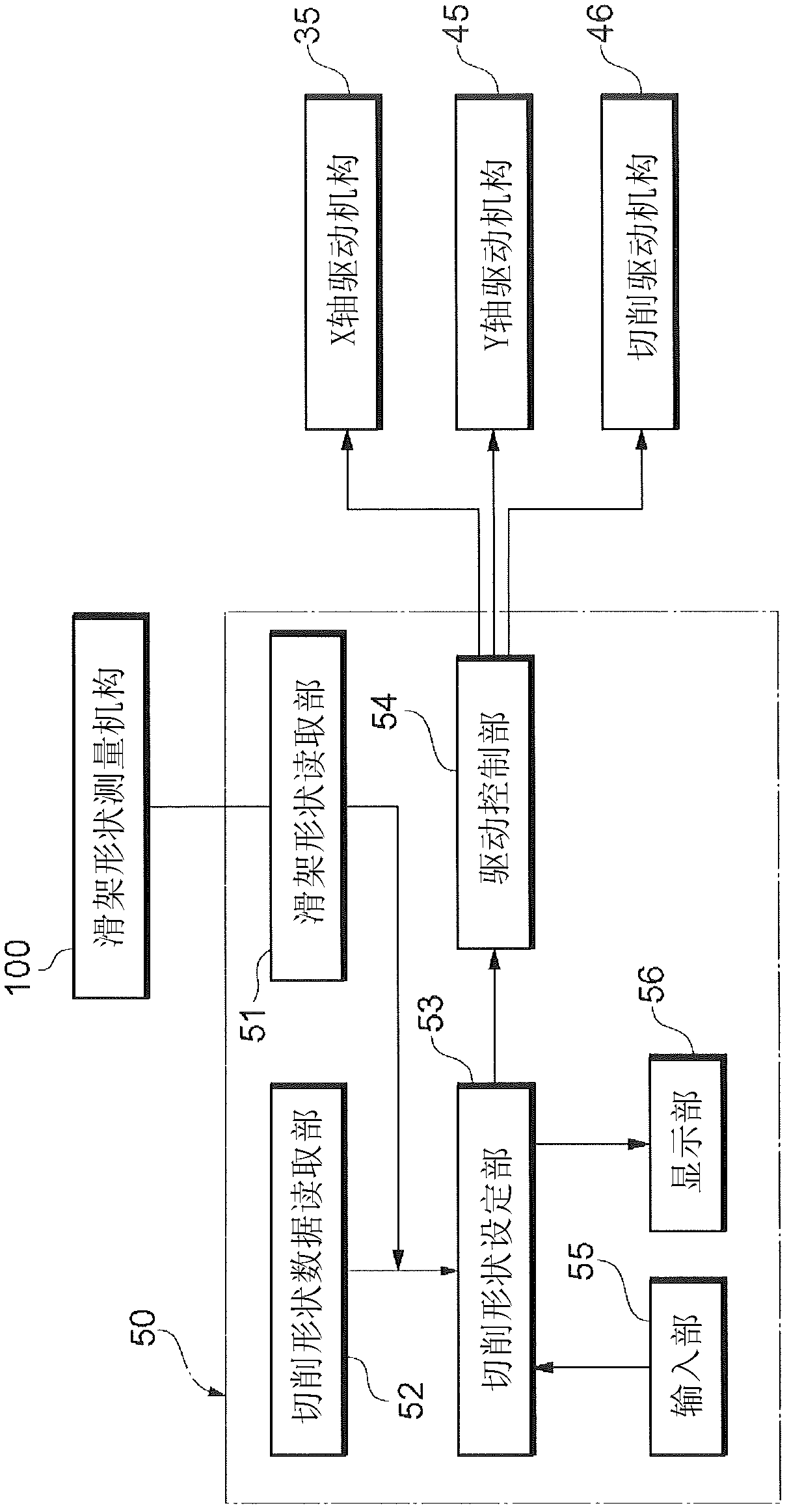

[0024] Next, preferred embodiments of the present invention will be described with reference to the drawings. As an example of a plotter (cutting device) to which the present invention is applied, figure 1 Indicates that a sheet-shaped medium to be processed is fixed and held on a processing table made of raw materials such as an acrylic plate, an aluminum composite plate, etc., and the end mill is brought into contact with the medium to be processed and raised and lowered relative to the medium to be processed, and A schematic structure of an X-Y plotter type cutting plotter 1 that moves in two orthogonal axis directions in a horizontal plane to cut a workpiece into a desired shape. In the description below, the figure 1 The upper direction in the paper is taken as the positive direction of the Z axis, figure 1 The lower right direction on the paper (the direction parallel to the Y rod 32 described later) is taken as the positive direction of the Y axis, figure 1 The l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com