Method for integral injection molding of bottom shell and rubber frame of backlight

A technology of backlight source and plastic frame, applied in the coating and other directions, can solve the problems of the thickness of the plastic frame not being too thin, high strength, etc., to achieve the effect of improving production efficiency, strong impact resistance, and saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

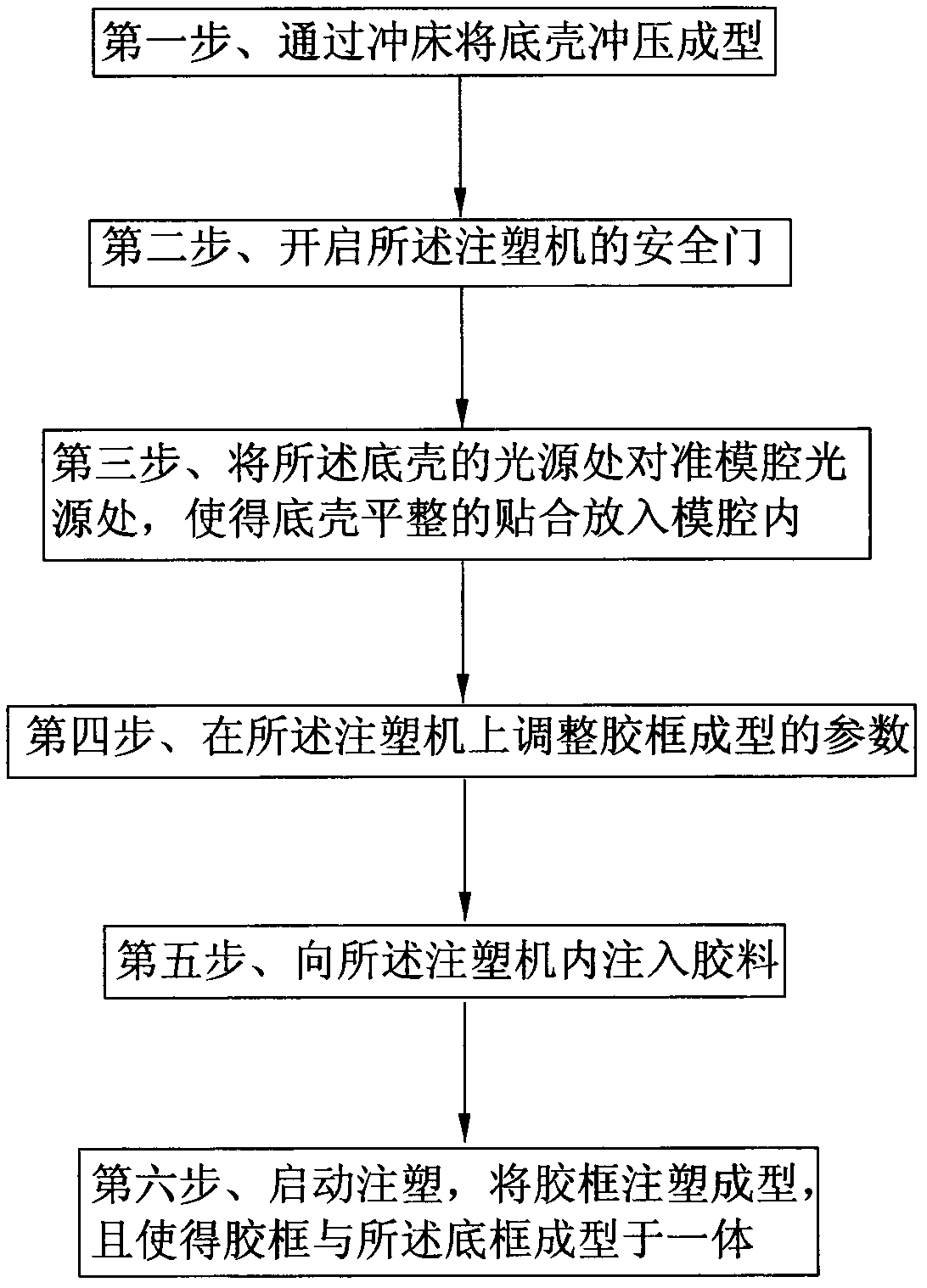

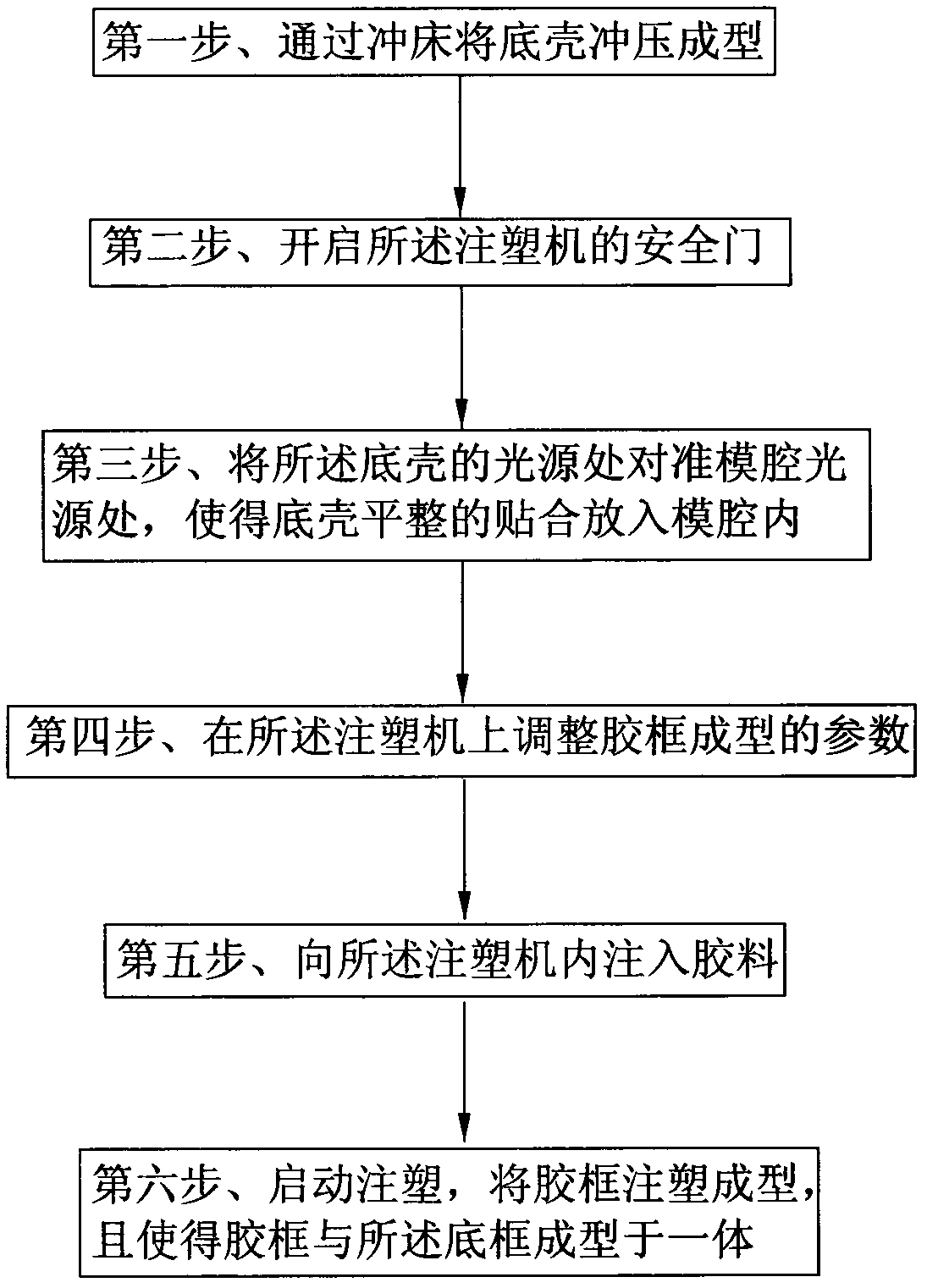

[0021] refer to figure 1 As shown, the method for the integral molding of the backlight source bottom shell and the plastic frame of the present invention by injection molding comprises the following steps:

[0022] The first step is to punch the bottom shell through a punching machine;

[0023] The second step is to open the safety door of the injection molding machine;

[0024] The third step is to align the light source of the bottom shell with the light source of the mold cavity, so that the bottom shell fits smoothly into the mold cavity;

[0025] The fourth step is to adjust the parameters of plastic frame molding on the injection molding machine;

[0026] The fifth step, inject rubber into the injection molding machine;

[0027] Step 6: Injection molding is started, the plastic frame is injection-molded, and the plastic frame and the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com