Engine fairing

A fairing and engine technology, used in aircraft parts, aircraft power units, aircraft power unit components, etc., can solve the problems of unsatisfactory heat insulation and heat resistance, slow application development of composite materials, and complexity of process manufacturing. Good heat insulation effect, improving the quality of the whole machine, and the effect of significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

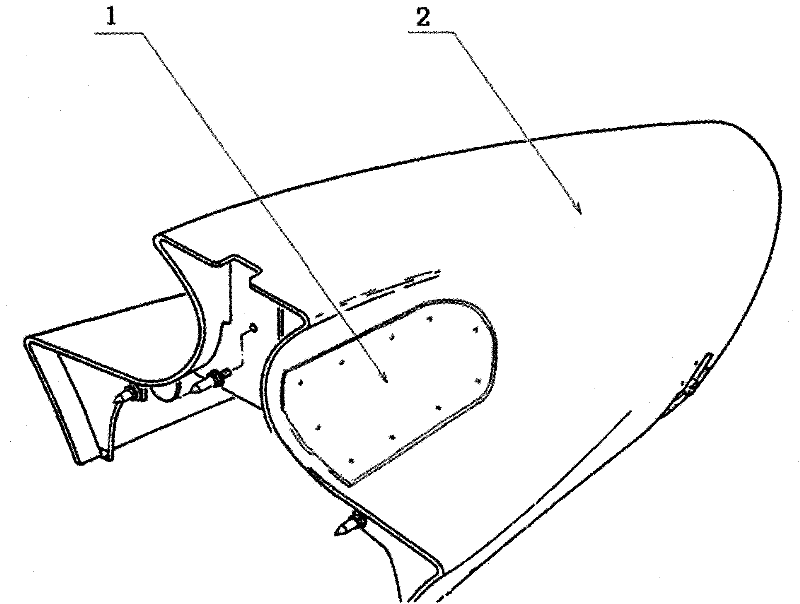

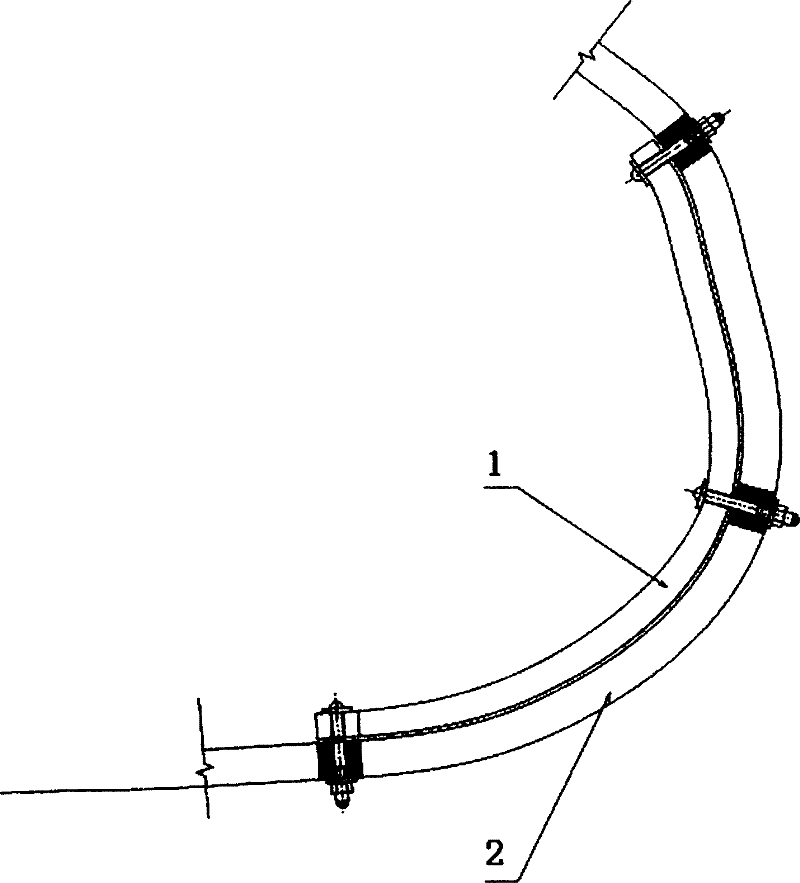

[0012] The present invention will be described in further detail below in conjunction with accompanying drawing, please refer to Figure 1 to Figure 3 .

[0013] like figure 1 and figure 2 As shown, a kind of engine cowling, the left and right sides of described engine cowling are installed with heat shield 1 respectively. The heat shield of the engine cowling is designed and formed by the method of the cowling mold tire comparison test, and is designed with an anisotropic surface, which can adapt to the complex structural shape of the engine cowling and achieve a good fit between the heat shield and the cowling. It is installed on the engine fairing by screwing, which is convenient for disassembly, installation and daily maintenance and inspection.

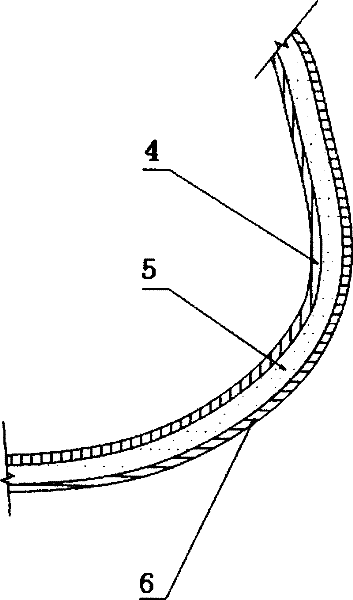

[0014] like image 3 As shown, the heat insulating sheet is composed of an inner skin 3, a heat insulating material 4, and an outer skin 5. The inner skin 4 and the outer skin 5 are all made of stainless steel. The outer ski...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com