Scraper type anti-blocking discharging bin

A technology of scraper type and silo, which is applied in the field of material unloading equipment, can solve problems such as blockage, and achieve the effects of easy promotion, reduced probability of blockage, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

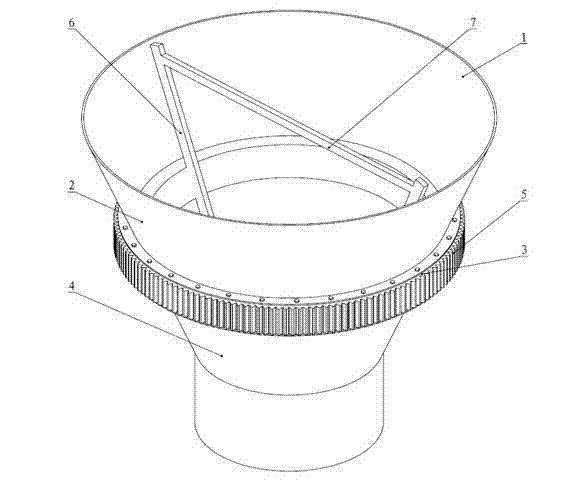

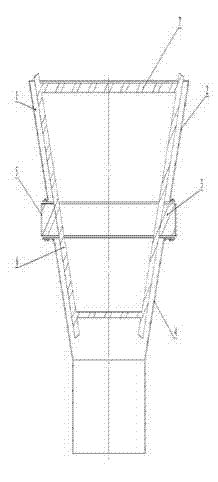

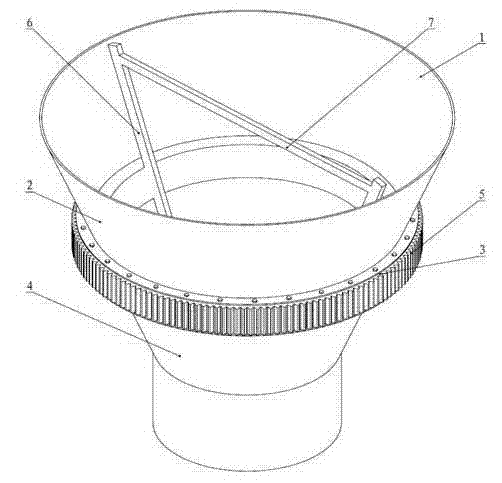

[0016] Referring to the accompanying drawings, the scraper type anti-blocking lower hopper of the present invention has a lower hopper body 1, wherein the lower hopper body is divided into upper, middle and lower parts; The silos are connected; the middle part is the rotating body 3, which is the easy-to-block part of the lower silo; the lower part is the fixed bin section 4, and its lower opening is connected with the feeder inlet plate; a gear 5 is fixedly arranged on the outer periphery of the rotating body , the motor drives the rotating body to rotate through the reducer and the gears on the periphery of the rotating body, and the inner wall of the rotating body is fixedly provided with a scraper 6 from top to bottom along the direction of the lower bin wall; the scraper 6 The upper part is close to the inner wall of the fixed bin section at the upper part of the lower silo, and the lower part of the scraper is close to the inner wall of the fixed bin section at the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com