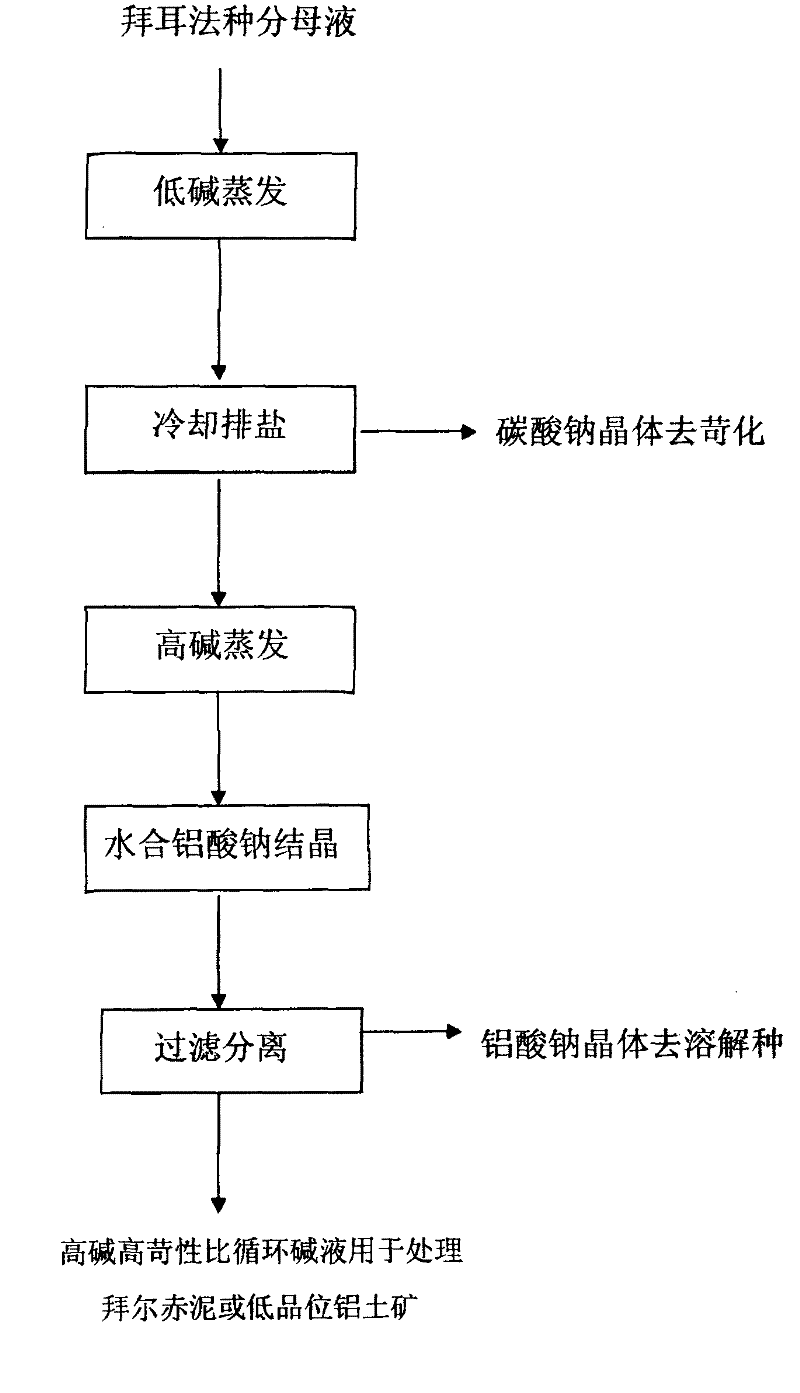

Method for preparing high-alkali high-causticity-ratio solution and improving traditional seed precipitation efficiency

A caustic ratio and solution technology, which is applied in the fields of preparing high-alkali and high caustic ratio solutions and improving the efficiency of traditional seed fractions, can solve the problems of high-alkali and high caustic ratio circulating lye and low seed fraction decomposition efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

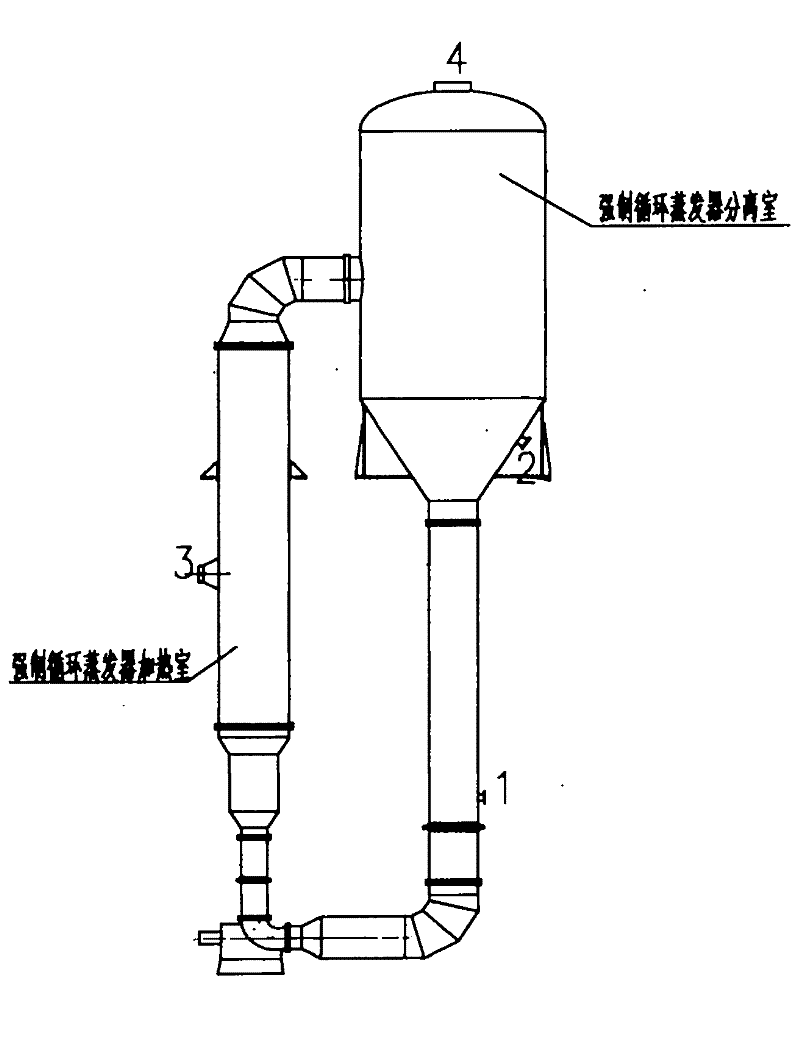

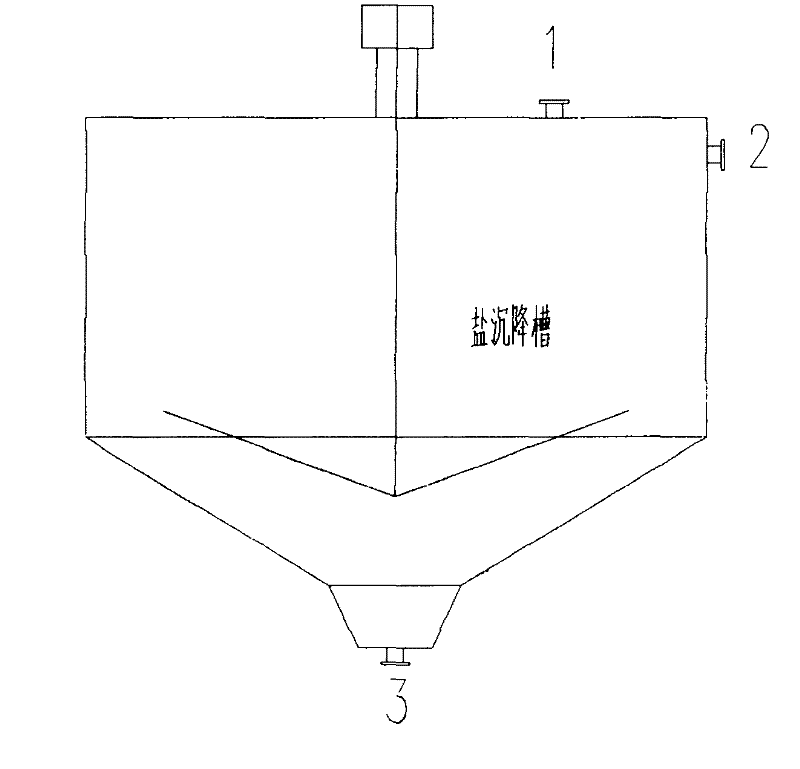

[0024] First, the Bayer process seed separation mother liquor is evaporated to a caustic alkali concentration of 320g / L in a forced circulation evaporator, and then the solution is introduced into the salt drain tank. After staying for 4 hours, sedimentation is carried out. The clear liquid after sedimentation separation The original liquid inlet is introduced into a forced circulation evaporator to evaporate the high alkali to a sodium oxide concentration of 530g / L, and then the sodium aluminate mother liquor is introduced into the crystallization reactor through the feed port, and the temperature in the crystallizer is controlled to 60°C and the stirring rate is 50 rpm Under the condition of 1 / min, crystallization is performed for 8 hours and then filtered to obtain hydrated sodium aluminate crystals and mother liquor. The causticity ratio of the obtained sodium aluminate hydrate crystals was 1.4, and seeded after dissolution. The causticity ratio of the mother liquor is incr...

Embodiment 2

[0026] First, the Bayer process seed separation mother liquor is evaporated to a caustic alkali concentration of 340g / L in a forced circulation evaporator, and then the solution is introduced into the salt drain tank. After staying for 6 hours, sedimentation and separation are carried out. The clear liquid after the fiber sedimentation separation is removed from The raw liquid inlet is introduced into the forced circulation evaporator to evaporate the high alkali to a sodium oxide concentration of 560g / L, and then the sodium aluminate mother liquor is introduced into the crystallization reactor through the feed port, and the temperature in the crystallizer is controlled to 50°C and the stirring rate is 50 rpm Under the condition of 1 / min, crystallization was carried out for 16 hours and then filtered to obtain hydrated sodium aluminate crystals and mother liquor. The causticity ratio of the obtained sodium aluminate hydrate crystals was 1.5, and seeded after dissolution. The ca...

Embodiment 3

[0028] First, the Bayer process seed separation mother liquor is evaporated to a caustic alkali concentration of 350g / L in a forced circulation evaporator, and then the solution is introduced into the salt drain tank. After staying for 8 hours, sedimentation separation is carried out. The clear liquid after sedimentation separation The raw liquid inlet is introduced into the forced circulation evaporator to evaporate the high alkali to a sodium oxide concentration of 580g / L, and then the sodium aluminate mother liquor is introduced into the crystallization reactor through the feed port, and the temperature in the crystallizer is controlled to 40°C and the stirring rate is 50 rpm Under the condition of 1 / min, crystallization was carried out for 20 hours and then filtered to obtain hydrated sodium aluminate crystals and mother liquor. The causticity ratio of the obtained sodium aluminate hydrate crystals was 1.6, which was directly dissolved and seeded. The causticity ratio of th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap