Flannelette ironing machine

An ironing machine, flannel technology, used in textiles and papermaking, fabric surface trimming, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

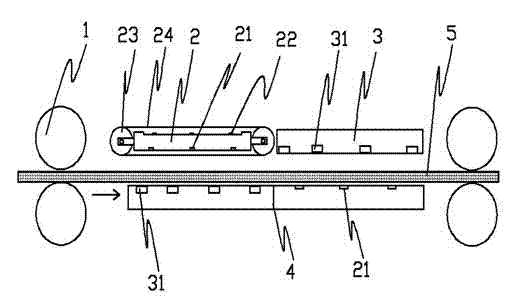

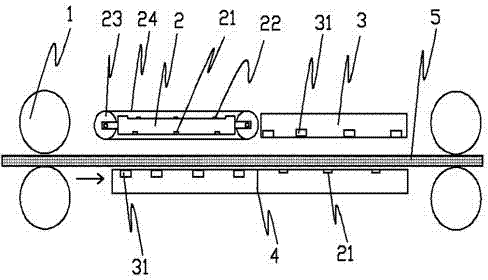

[0018] figure 1 Shown is a schematic diagram of the structural shape of an embodiment of the fleece ironing machine.

[0019] In this embodiment, the flannelette ironing machine includes two pairs of cloth conveying rollers 1 located at the outlet and the inlet side of the ironing machine body. Composition, the first ironing board on the upper side is divided into the first functional block 2 and the second functional block 3 with the vertical line as the dividing point, and the two ends of the first functional block 2 near the entrance of the ironing machine body are set There are conveying shafts 23, and the conveying shafts 23 are fixed on the first functional block 2 through brackets. The two conveying shafts 23 are surrounded by ironing belts 24. The top of the first functional block 2 is evenly distributed with three water Mist nozzles 22, three steam nozz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com