Overhead maintenance passage for diversion tunnels

A technology for water diversion tunnels and maintenance channels, which is applied in water conservancy projects, hydroelectric power plants, hydropower stations, etc. It can solve the problems of inconvenient maintenance operations, water accumulation in maintenance branch tunnels, and inconvenient maintenance, so as to reduce the difficulty of construction and reduce the cost of construction. cost and ease of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

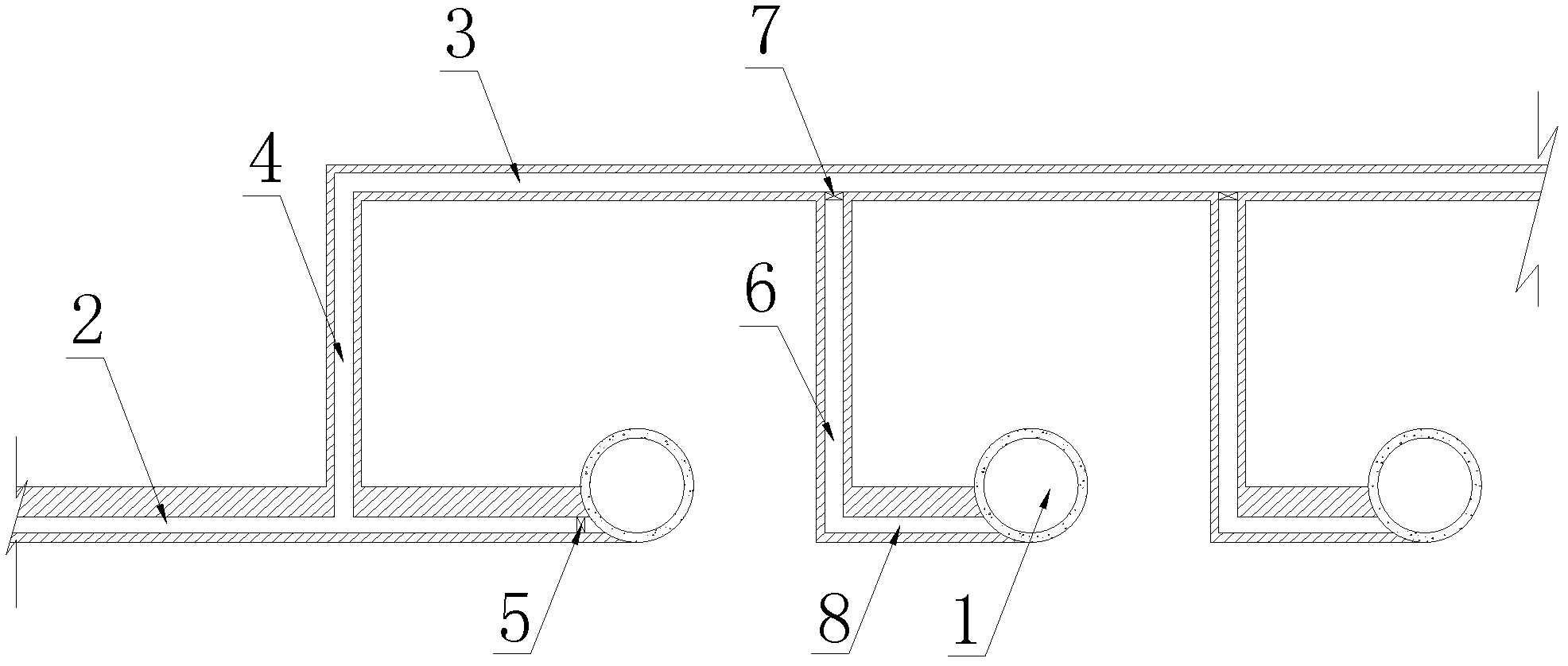

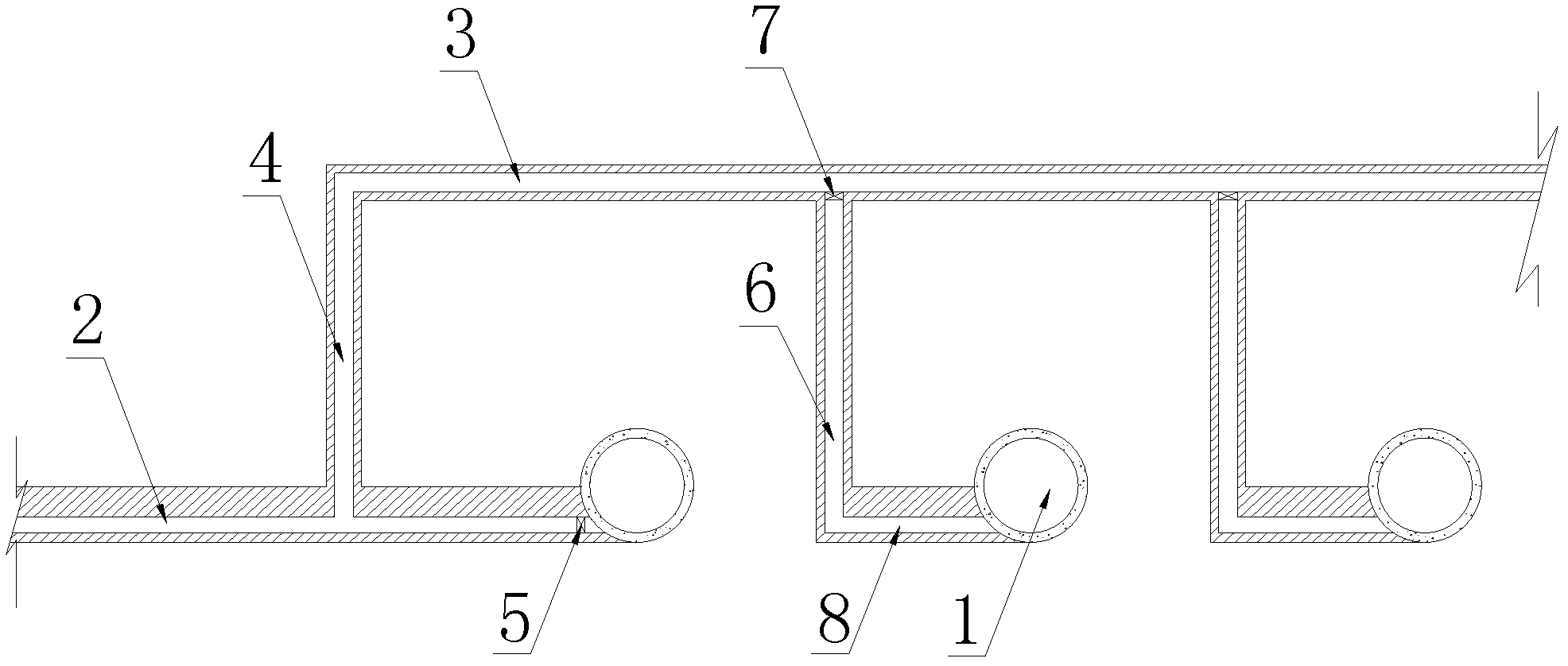

[0017] Such as figure 1 As shown, the upper-span overhaul channel for multiple water diversion tunnels, including the construction tunnel formed when the water diversion tunnel 1 is excavated, will block the construction tunnel between the two water diversion tunnels 1, and the unblocked construction tunnel The external maintenance flat hole 2 is formed, and the upper maintenance branch hole 3 is also included. The position of the upper maintenance branch hole 3 is higher than the position of the external maintenance flat hole 2. The upper maintenance branch hole 3 passes through the external maintenance shaft 4 and the external maintenance flat hole 2 The upper maintenance branch tunnel 3 communicates with the water diversion tunnel 1 through the internal maintenance shaft 6, and a sealing structure is set on the external maintenance flat tunnel 2 betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com