Double-cavity hydraulically coupled anti-flying device

A cavity fluid, anti-flying technology, applied in the field of hydraulic components, can solve problems such as accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

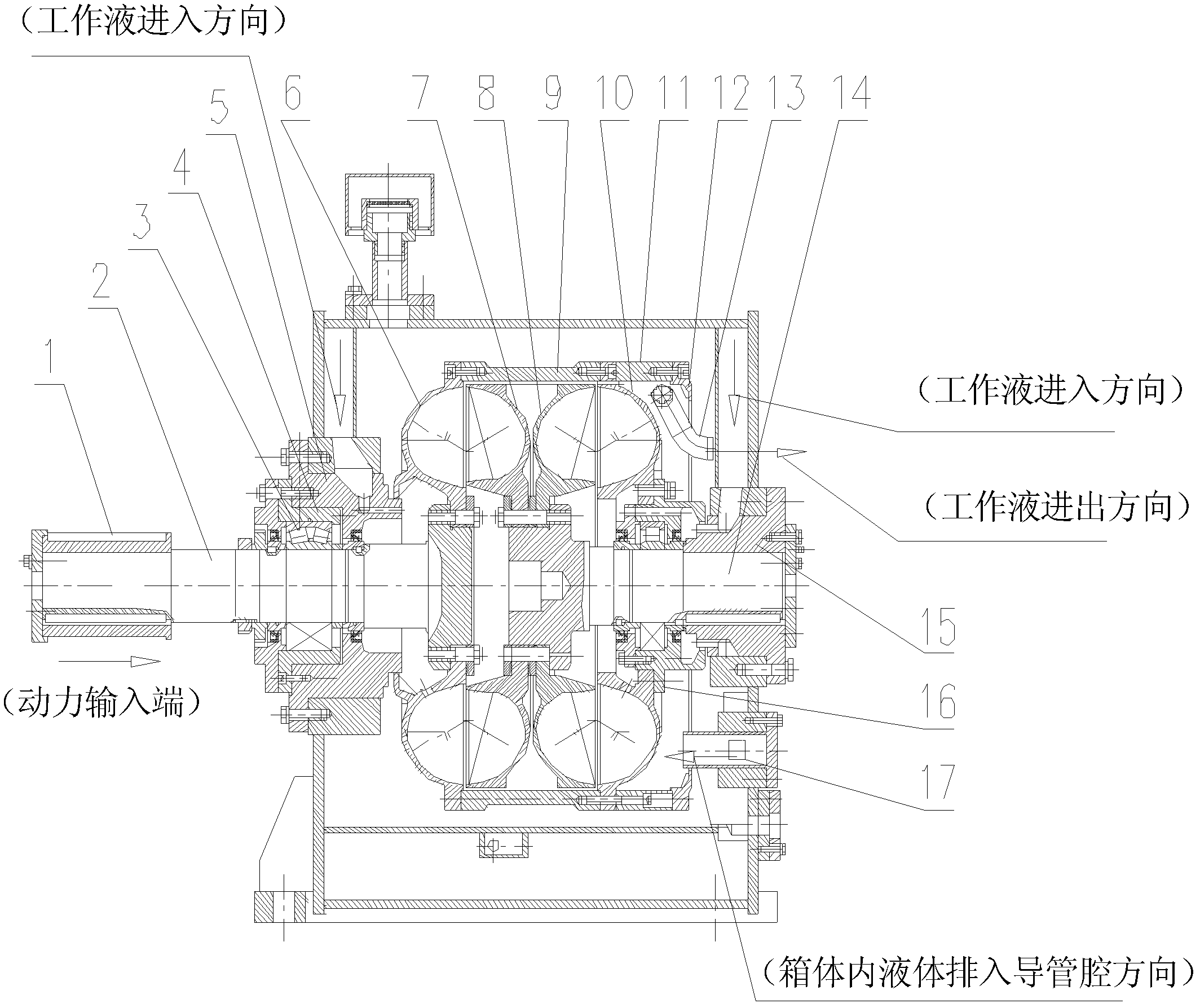

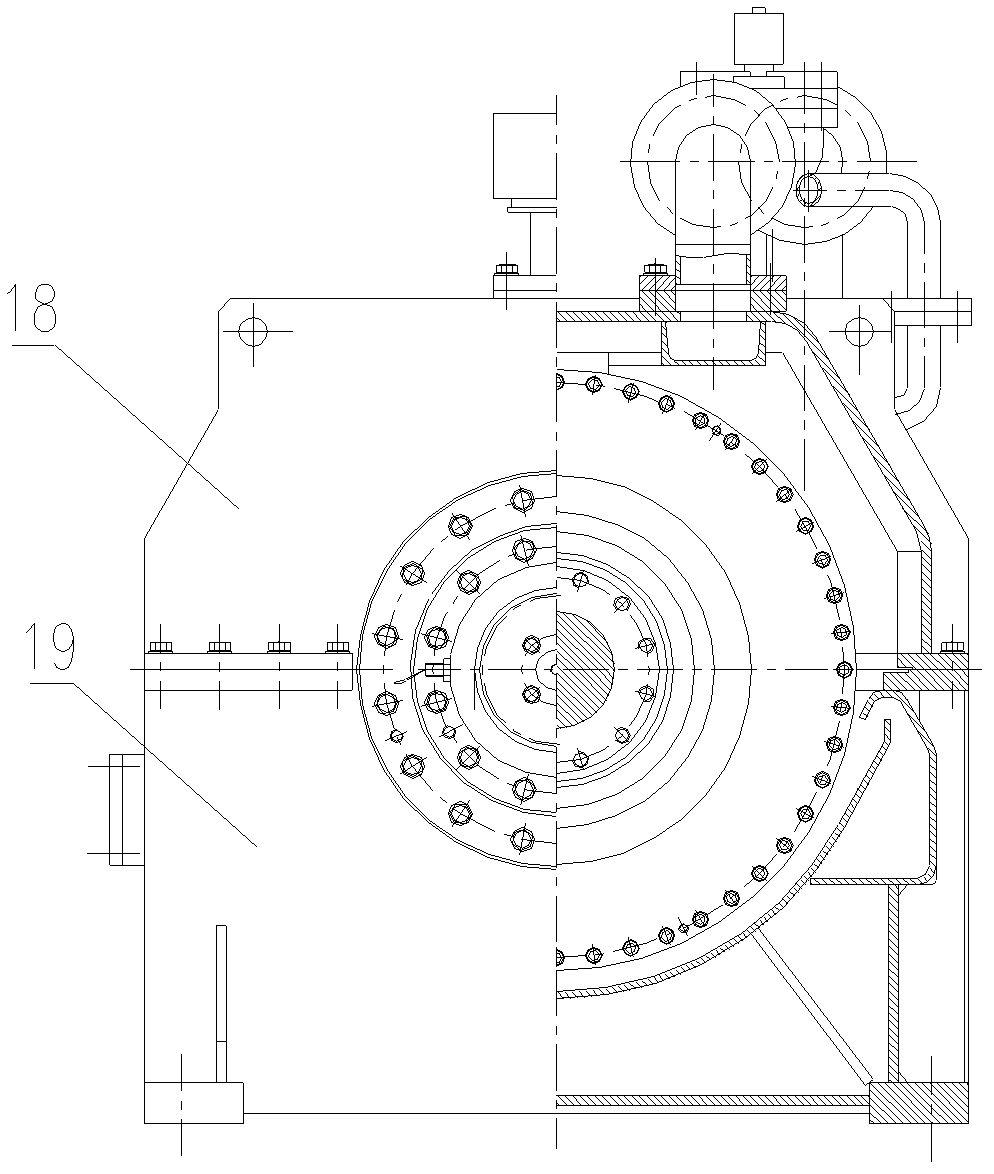

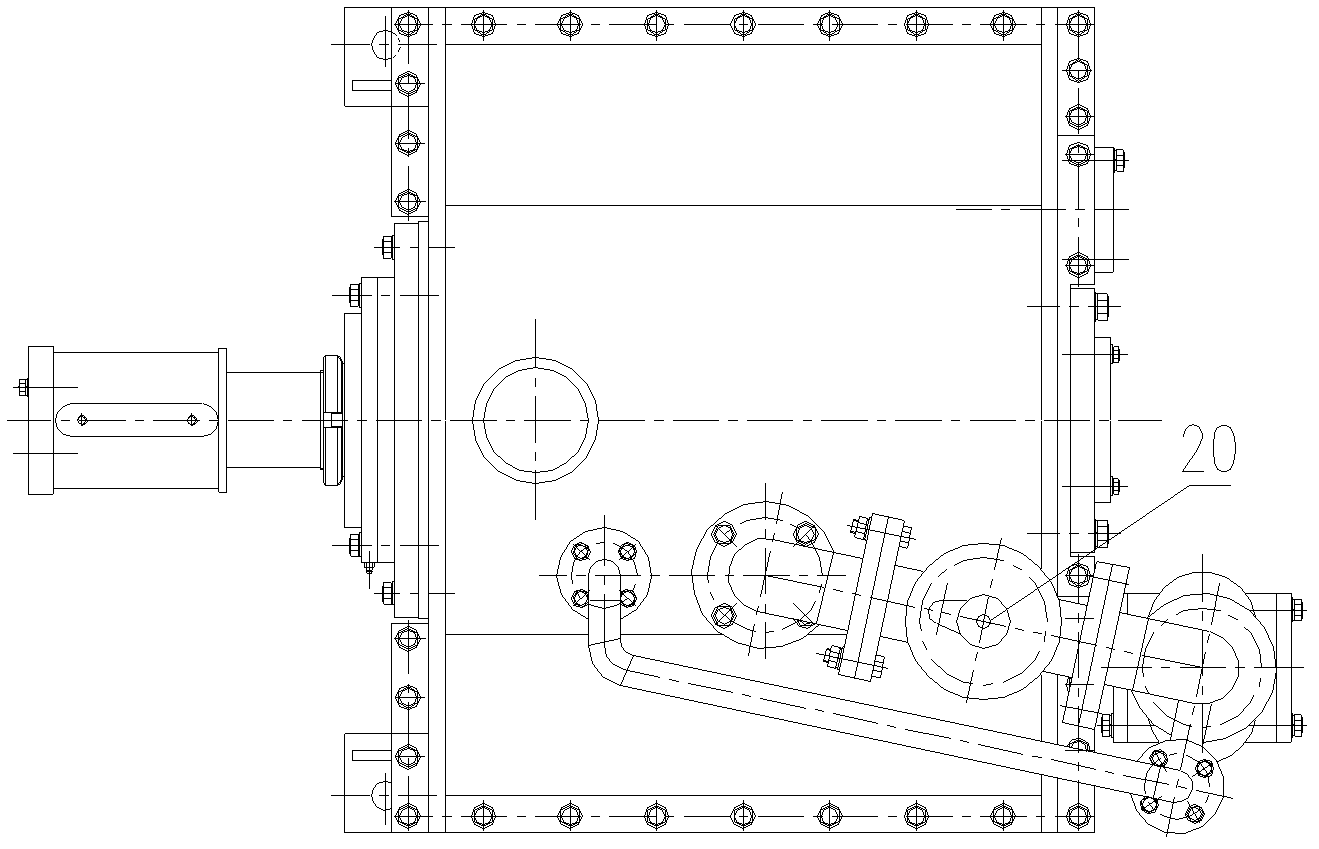

[0018] Such as figure 1 , 2 , 3, 4, and 5, the double-cavity hydraulic coupling anti-flyaway device of the present invention includes a casing 25, a rotating assembly, and a liquid supply system.

[0019] The box body 25 is composed of a box seat 19 and a box cover 18, and the box body 25 supports the entire liquid supply system;

[0020] The rotating assembly includes an input assembly and an output assembly;

[0021] The input components mainly include: input shaft 2, pump wheel A, pump wheel B, pump wheel connection cylinder 9, casing connection cylinder 11 and casing, etc.;

[0022] The output components mainly include: turbine A, turbine B, output shaft 14, etc.;

[0023] Such as Figure 5 As shown, the pulley sleeve 1 on the input shaft 2 of the input assembly is connected to the working machine 23 through a transmission mechanism 24, and the output assembly is fixedly connected to the box body 25; the transmission mechanism 24 shown is a belt transmission structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com