Semi-submersible anchoring type offshore wind generating set with integrated pedestal

A technology for wind power generators and generators, which is applied in the field of steel structure foundations, and can solve problems such as high costs, high requirements for seabed environmental conditions, and long construction periods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

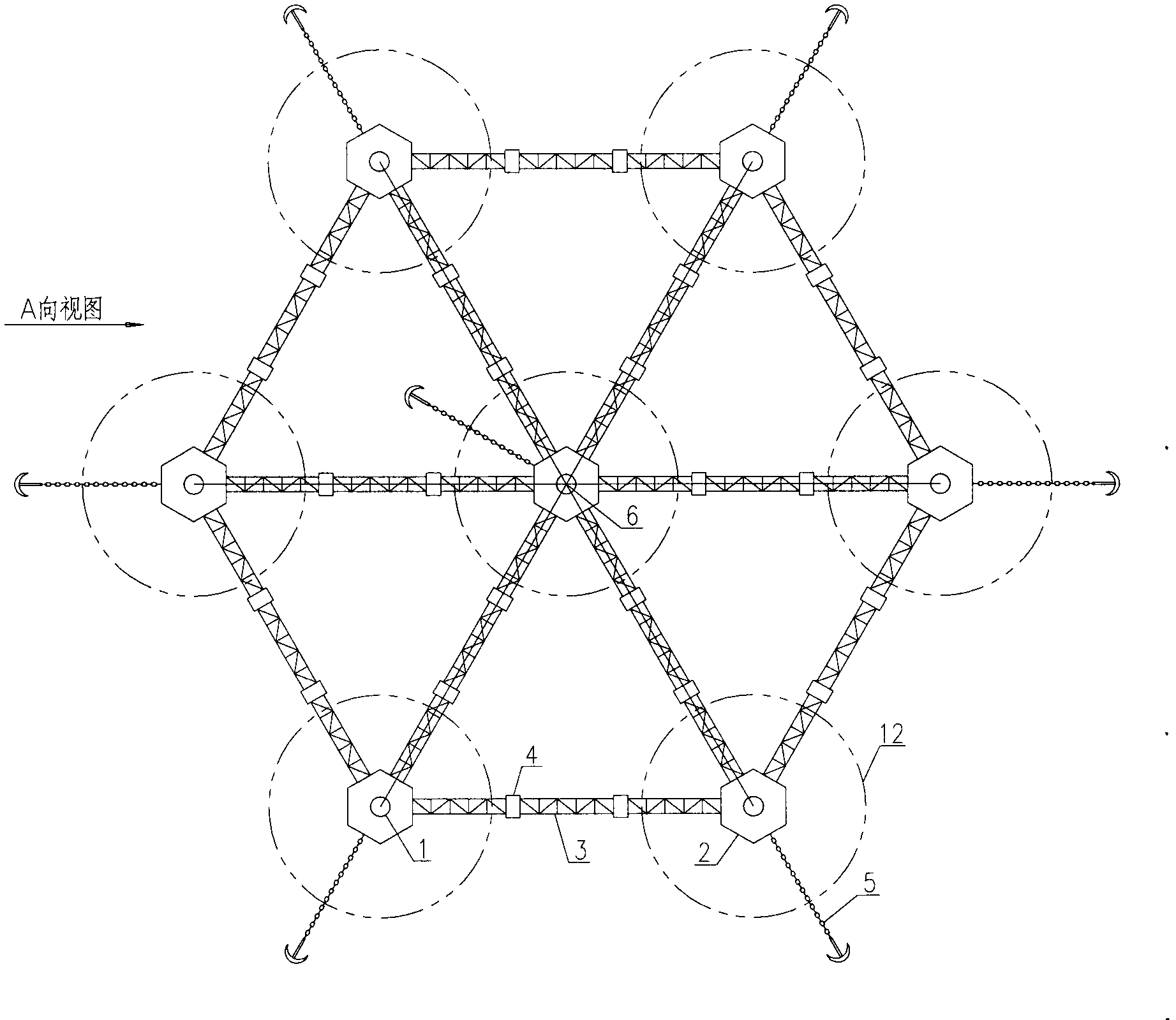

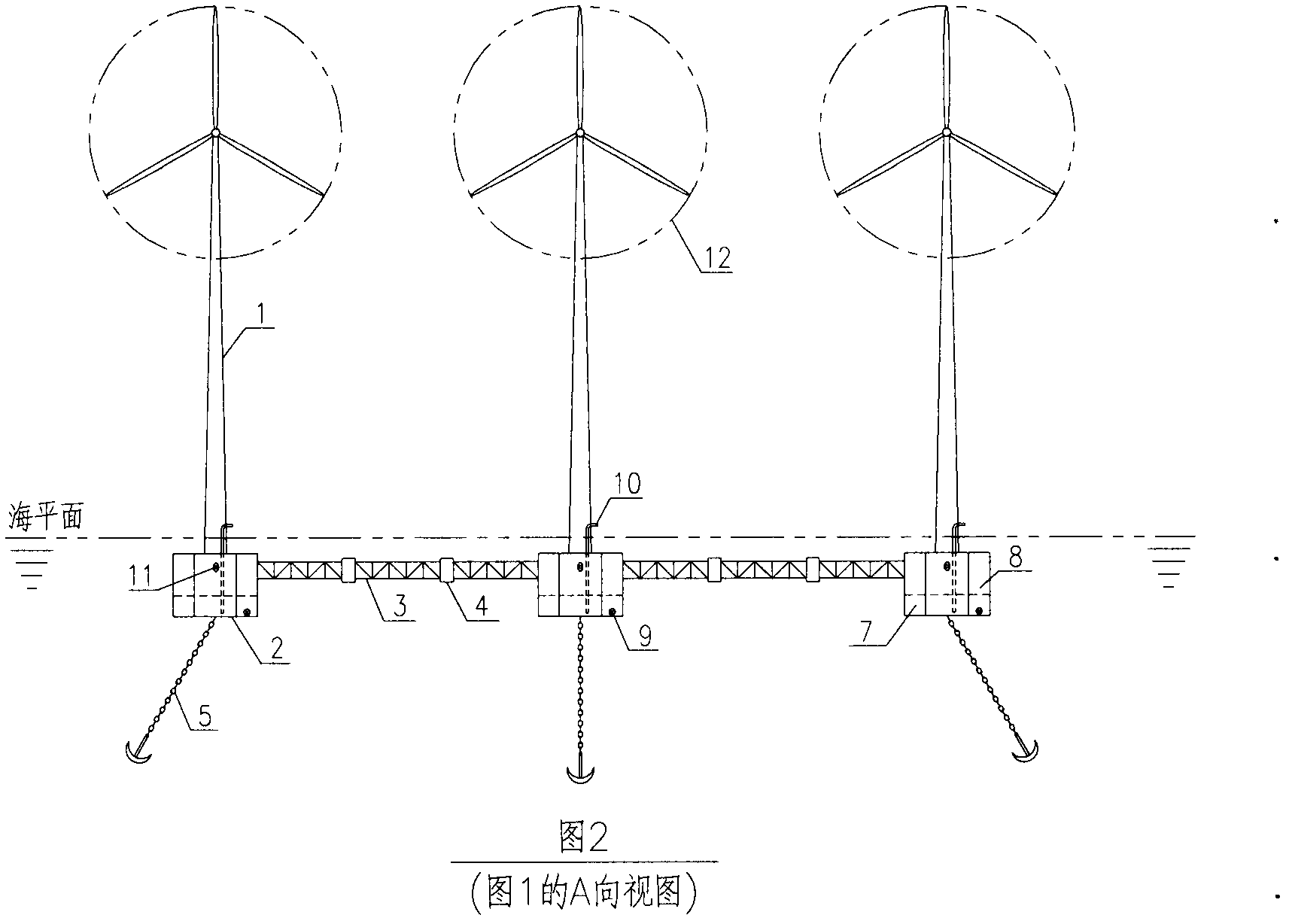

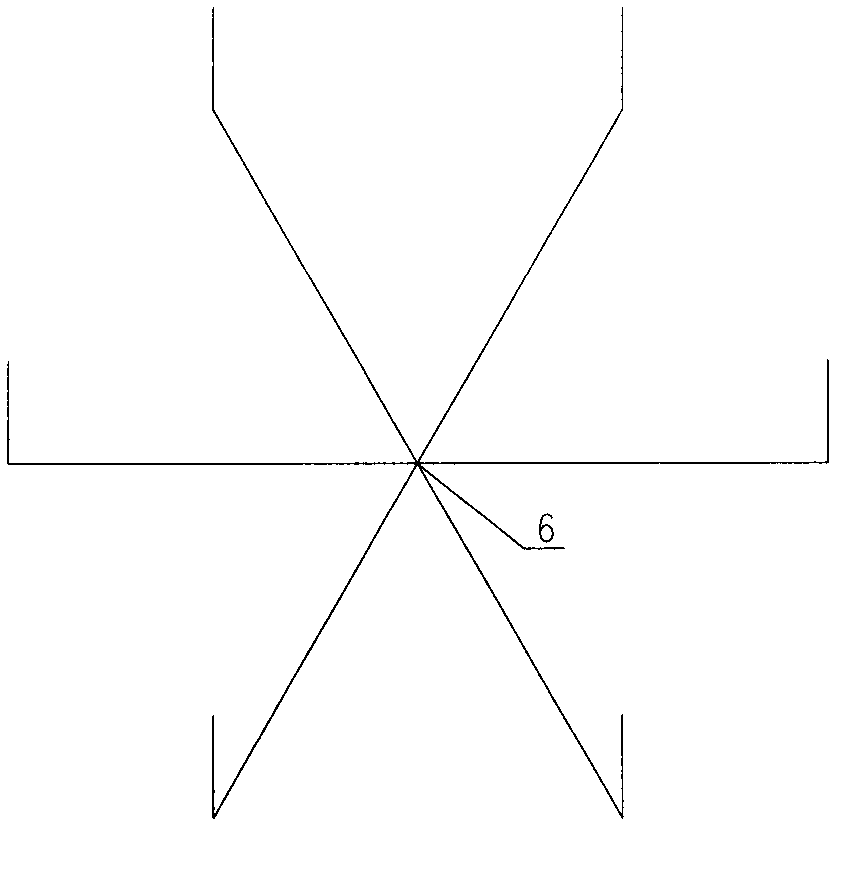

Embodiment Construction

[0028] According to the design requirements, design and manufacture the semi-submersible foundation buoyancy box 2 at the bottom of the column, the lattice truss support beam 3, the support beam buoyancy box 4, and the seabed mooring facilities 5. Assemble the generator set on the beach when the sea tide is low, the generator set is in a floating state after the sea tide ebbs, use a tugboat to tow the generator set to the designated sea area, open the sea bottom valve 9, inject seawater into the ballast tank 7, adjust with ballast water The levelness of the generating set makes the whole conjoined foundation submerged underwater, and then anchors the generating set with the seabed mooring facility 5 . If the generating set needs to be moved again, the mooring is released, the ballast water is discharged, the towing cable is attached, and the generating set is dragged by the tugboat to a new designated sea area.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com