Vehicle gear selection mechanism and automobile

A technology for shifting gears and vehicles, which is applied in the direction of mechanical equipment, engine components, and engine lubrication. It can solve the problems of easy air-drying loss, insufficient lubrication, and waste of lubricating grease, so as to improve NVH performance and avoid parts wear. , The effect of reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

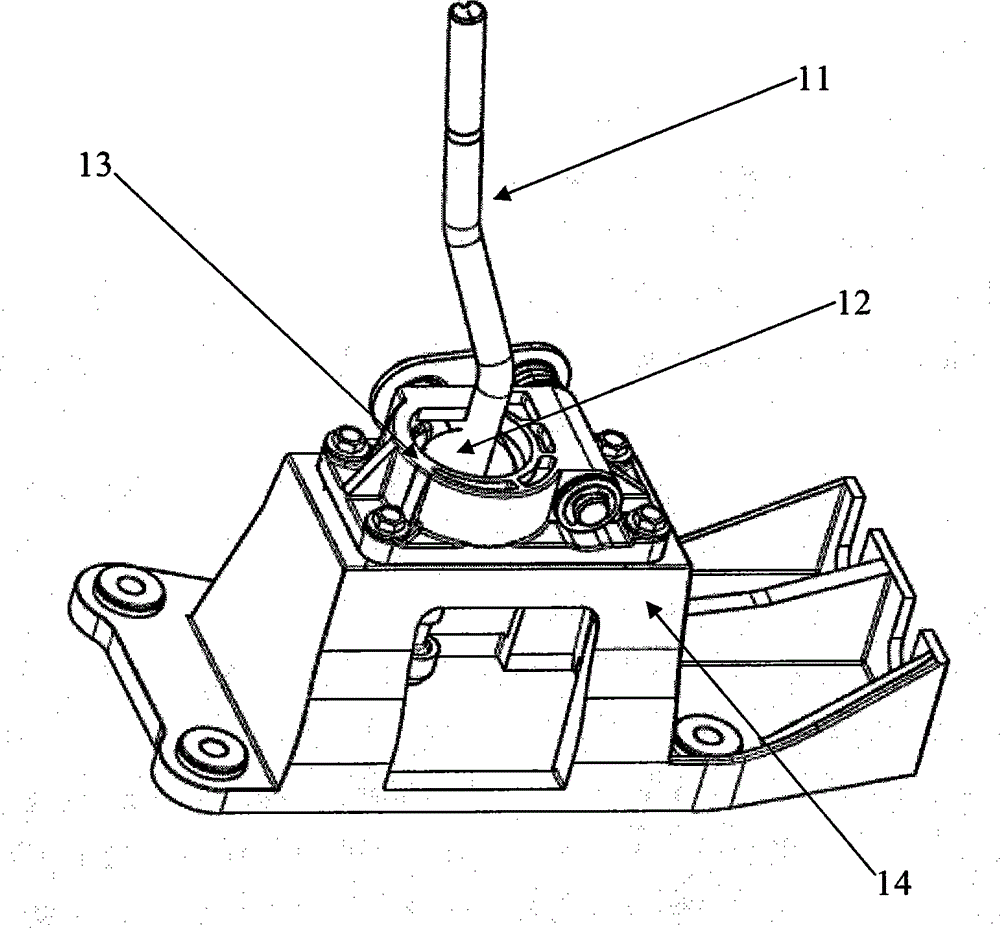

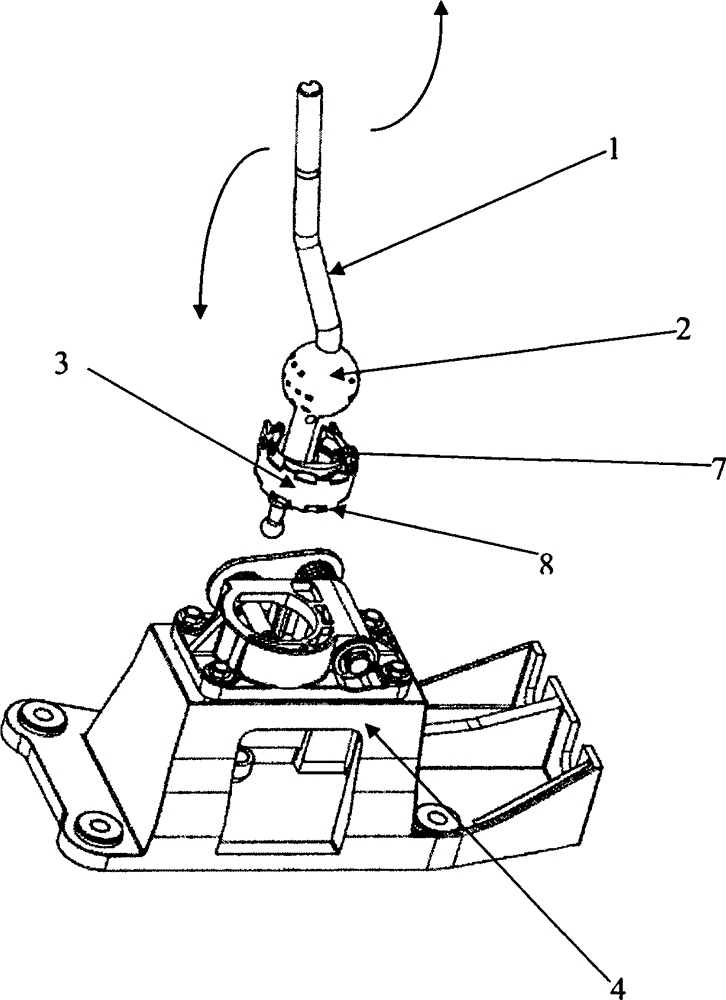

[0033] Such as figure 2 As shown, in this embodiment, the vehicle gear selection mechanism includes a base 4, a gear selection lever 1, a ball head sheath 3 with a spherical inner cavity, a ball head body 2, and an oil storage unit. Wherein, the ball head sheath 3 is arranged on the base 4 , the ball head body 2 is arranged at one end of the shift lever 1 , and the ball head body 2 is embedded in the spherical inner cavity of the ball head sheath 3 . The movement of the shift lever 1 drives the ball body 2 to rotate in the spherical inner cavity of the ball sheath 3 .

[0034] In this example, if Figure 5 As shown, the ball head sheath 3 includes a sheath upper part 7 and a sheath lower part 8, and the sheath upper part 7 and the sheath lower part 8 are detachably connected together to form a spherical inner cavity together, and the ball head body 2 is embedded in the in the spherical cavity.

[0035] Lubricating grease is stored in the oil storage unit, and the oil stora...

Embodiment 2

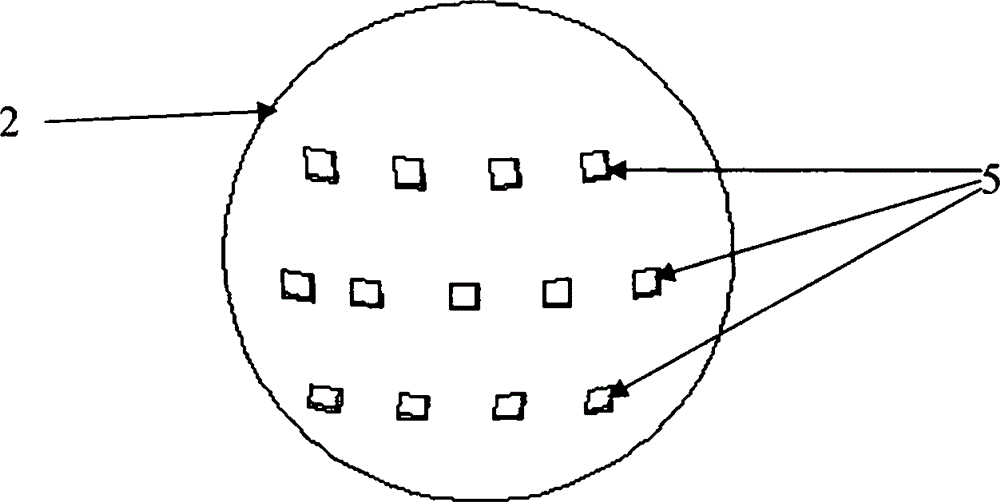

[0048] The difference between this embodiment and Embodiment 1 is that: in this embodiment, the oil storage unit includes a first groove 5 provided on the ball head body 2, and lubricating grease is arranged in the first groove 5 . That is to say, the oil storage unit does not have the second groove 6 provided on the ball head sheath 3 .

[0049] Other structures in this embodiment are the same as those in Embodiment 1, and will not be repeated here.

[0050] In this embodiment, only the first groove 5 is provided on the ball head body 2, and the ball head sheath 3 is not provided with a groove. In close contact, when the lubricating grease in the first groove 5 lubricates itself, a part of the lubricating grease will adhere to the ball sheath 3 and play the role of lubricating the ball sheath 3 at the same time. However, the ball head sheath 3 is only lubricated by the lubricating grease in the first groove 5, lacks its own lubrication, let alone lubricates the ball body 2, ...

Embodiment 3

[0052] The difference between this embodiment and Embodiment 1 is that in this embodiment, the oil storage unit includes a second groove 6 opened on the ball head sheath 3, and the second groove 6 is provided with lubricating grease . That is, the oil storage unit does not have the first groove 5 provided on the spherical body 2 .

[0053] Other structures in this embodiment are the same as those in Embodiment 1, and will not be repeated here.

[0054] In this embodiment, since only the second groove 6 is set on the ball head sheath 3, no groove is set on the ball head body 2. When the lubricating grease in the second groove 6 lubricates itself, a part of the lubricating grease will adhere to the ball body 2 and play the role of lubricating the ball body 2 at the same time. However, if the ball body 2 is only lubricated by the lubricating grease in the second groove 6, and lacks its own lubrication, let alone lubricate the ball sheath 3, its effect is not as good as that of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com