Sealing device and bearing device provided with the same

A technology for sealing devices and bearing devices, which is applied in the field of bearing devices and sealing devices, and can solve problems such as reduced bearing life and reduced sealing performance of sealing devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Hereinafter, embodiments of the sealing device and the bearing device including the sealing device according to the present invention will be described in detail with reference to the drawings. In addition, this invention is not limited to the above-mentioned illustration, It is disclosed by a claim, and all changes within the meaning and range equivalent to a claim are included.

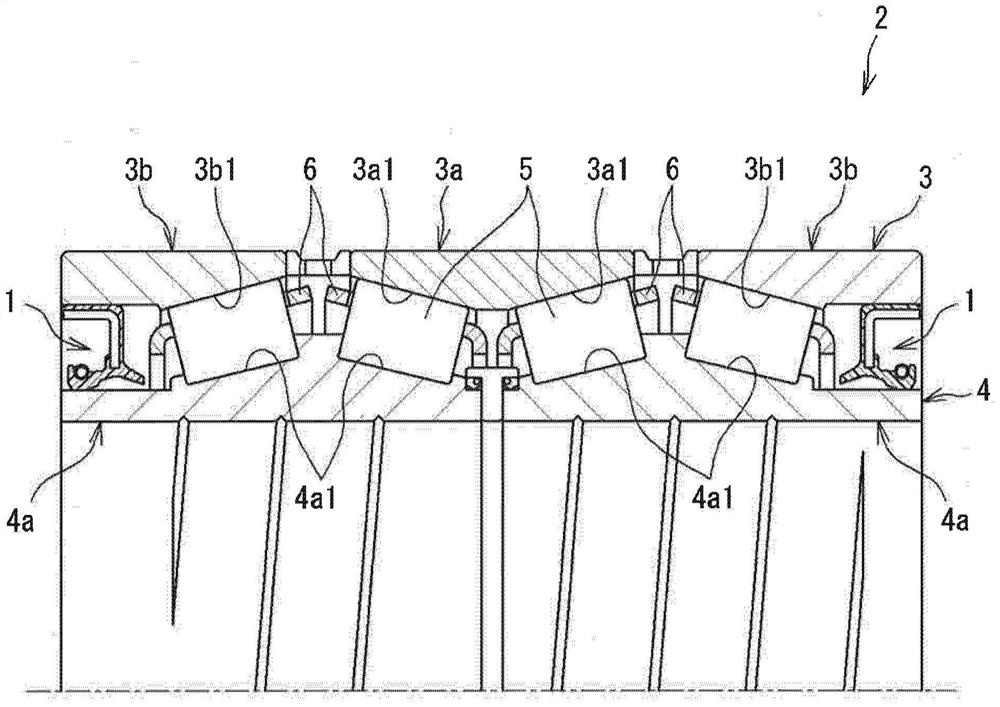

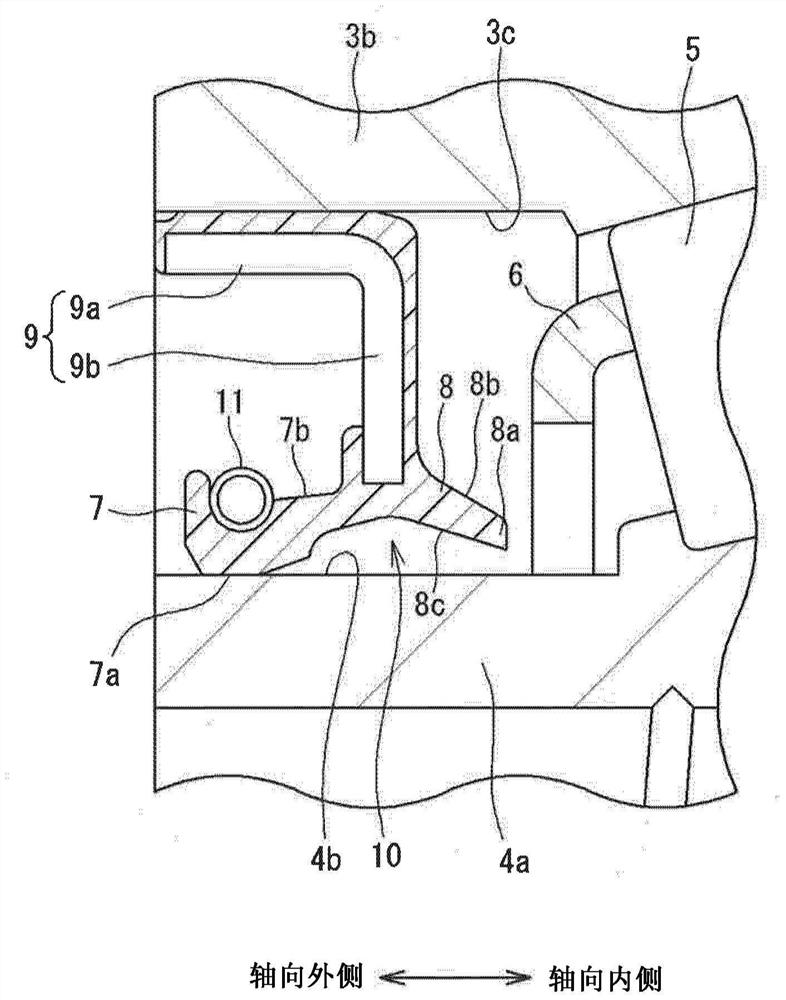

[0027] figure 1 It is a cross-sectional explanatory view showing the structure of a bearing device 2 provided with a sealing device 1 according to an embodiment of the present invention, figure 2 yes figure 1 An enlarged cross-sectional explanatory view of the sealing device 1 shown. The bearing device 2 is a rolling bearing device that is provided on roll necks (not shown) at both ends of a roll for a rolling mill to rotatably support the roll. The bearing device 2 includes an outer ring 3 , an inner ring 4 , tapered rollers 5 as rolling elements, a cage 6 , and a sealing device 1 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com