Backlight module and display device adopting the backlight module

A technology for a backlight module and a display device, applied in the field of surface light sources, can solve the problems of high material cost, disadvantageous narrow frame and light weight, and many materials, and achieve the effect of reducing weight and material cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

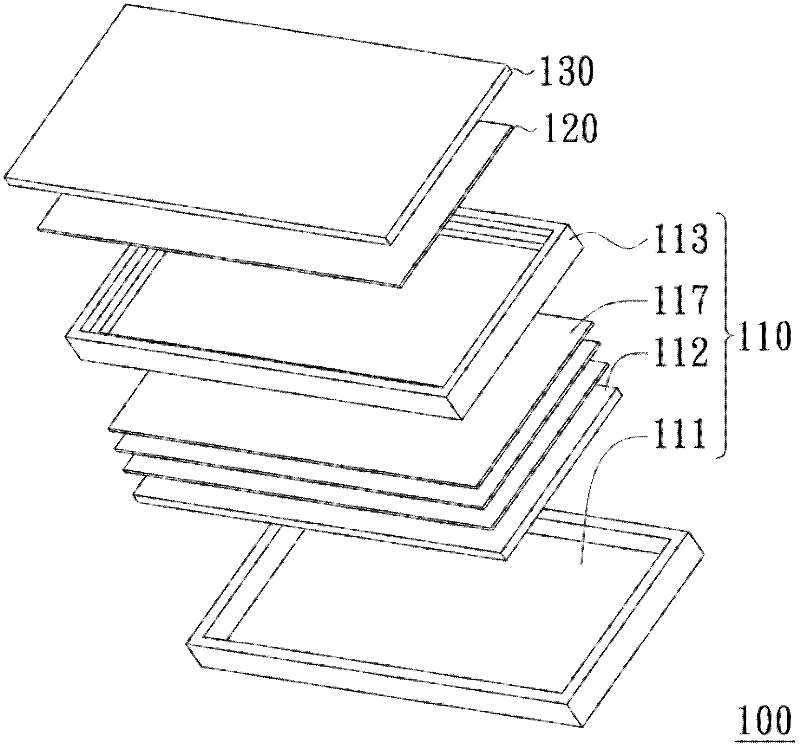

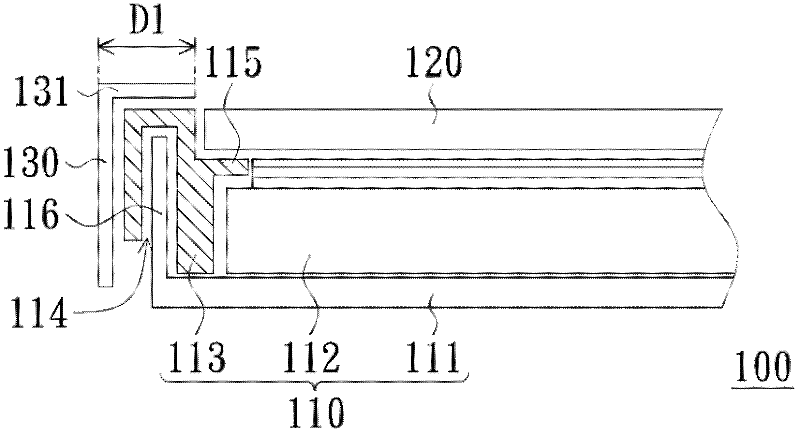

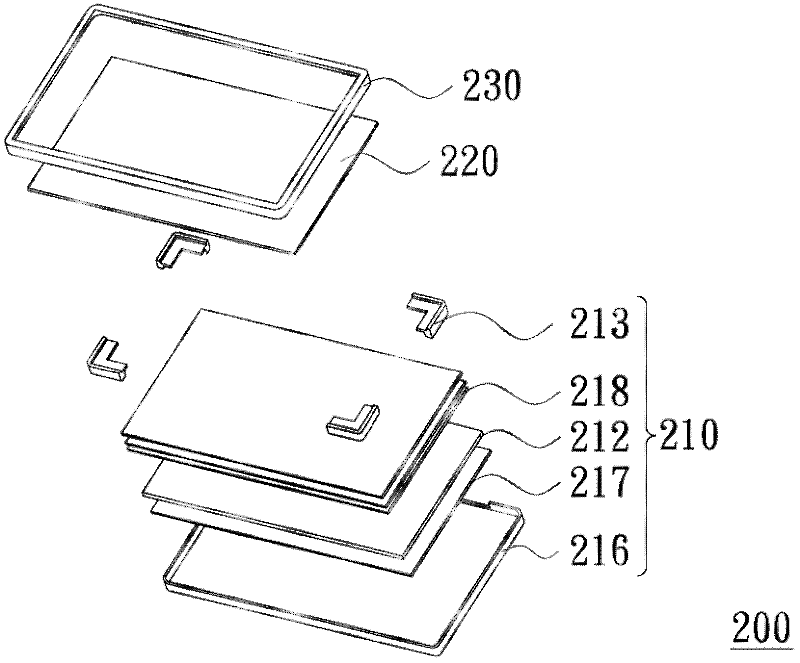

[0071] image 3 It is an exploded perspective view of a display device according to an embodiment of the present invention. Figure 4 for image 3 A partial three-dimensional cross-sectional schematic diagram of the display device shown. Figure 5 for image 3 A three-dimensional schematic view of the support of the display device shown. see Figure 3 to Figure 5, the display device 200 of this embodiment includes a backlight module 210 and a display panel 220 . The backlight module 210 includes an optical component 212 and a plurality of support members 213 . These supporting pieces 213 are disposed on the edge of the optical member 212 . Each supporting member 213 has a side wall 214 and a supporting portion 215 , the side wall 214 is located beside the edge of the optical component 212 , and the supporting portion 215 extends from the side wall 214 to the top of the optical component 212 . The side wall 214 has a first portion 214a located below the support portion 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com