Control device and method for on-line monitoring of safety risk of four pipelines outside furnace of boiler of power station

A technology for power station boilers and safety risks is applied in the field of online monitoring and control devices for the safety risks of the four major pipelines outside the power station boiler furnace, and can solve the problems of online monitoring and control functions without the safety risks of the four major pipeline outside the power station boiler furnaces.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

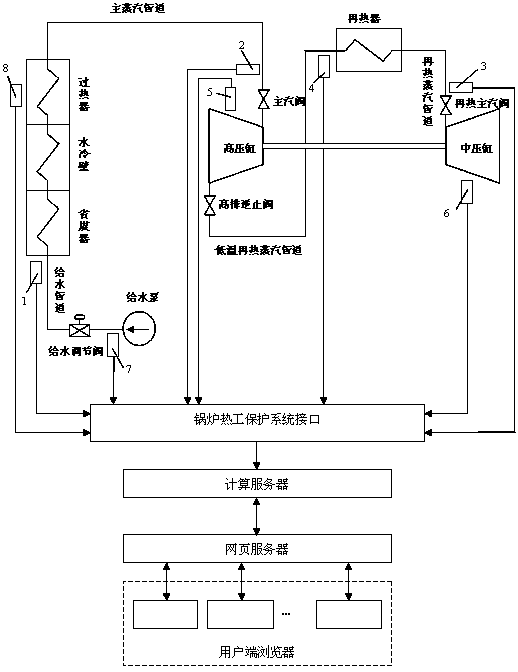

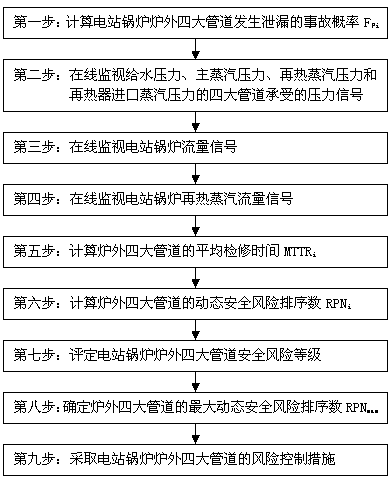

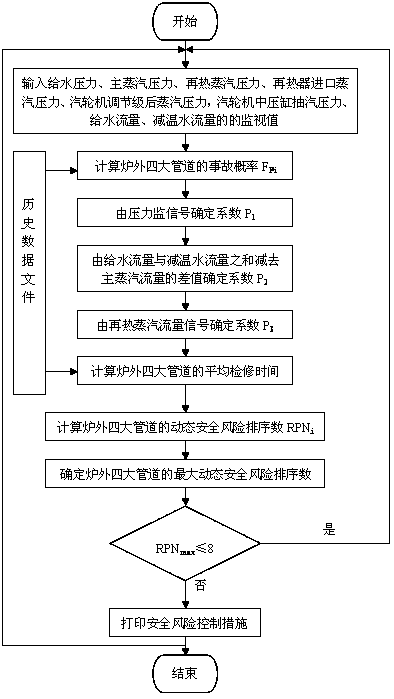

[0041] Such as figure 1 As shown, the block diagram of the online monitoring and control method for the safety risks of the four major pipelines outside the power plant boiler furnace of the present invention, the online monitoring and control device for the safety risks of the four major pipelines outside the power plant boiler furnace of the present invention consists of a boiler economizer inlet water supply pressure sensor 1, Main steam pressure sensor 2, reheat steam pressure sensor 3, reheater inlet steam pressure sensor 4, steam turbine regulating stage steam pressure sensor 5, steam turbine medium pressure cylinder extraction pressure sensor 6, feed water flow orifice plate 7, desuperheating water flow Orifice plate 8, power station boiler thermal protection system interface, computing server, web server and client browser, install two boiler economizer inlet water supply pressure sensors 1 on the water inlet pipe of the boiler economizer inlet header, Two main steam p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com