Exhaust manifold side position and end face inspection tool

An exhaust manifold and end face technology is applied in the field of the side position of the exhaust manifold and the end face inspection tool, which can solve the problems of missing detection pins, abrasion of detection pins, inaccurate detection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

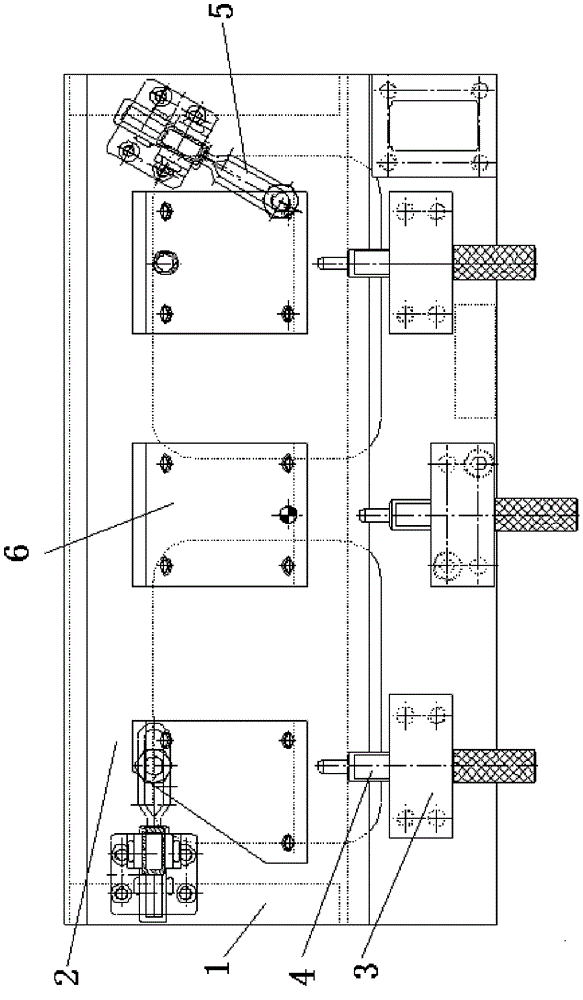

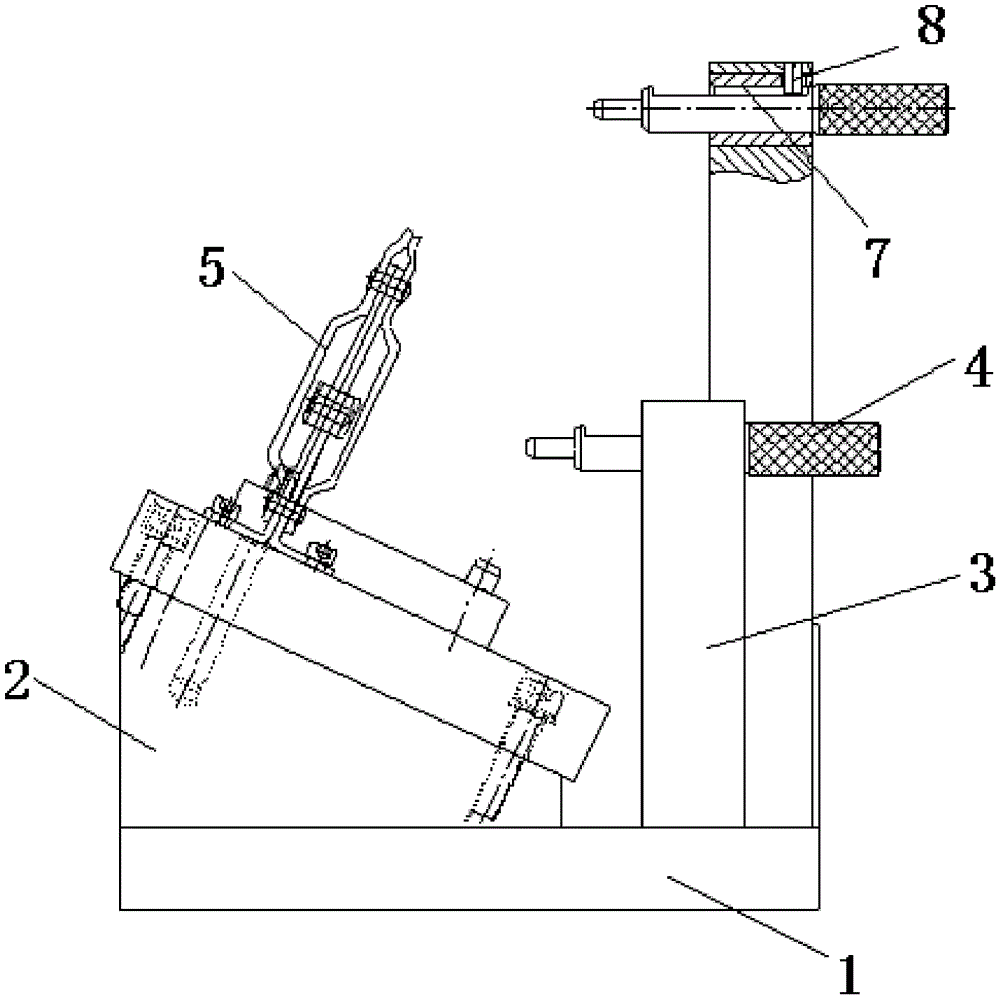

[0011] Referring to the accompanying drawings, a side position and end surface inspection tool for an exhaust manifold includes a base plate 1 and a bracket 2, the bracket 2 is fixed on one side of the base plate 1, and the other side of the base plate 1 is provided with a plurality of vertical The detection board 3 is provided with detection pins 4, the left and right ends of the bracket 2 are respectively provided with quick clamps 5, and a plurality of backing plates 6 are arranged between the left and right quick clamps 5.

[0012] The angle between the plane of the bracket 2 and the bottom plate 1 is 20° to 30°.

[0013] The detection pin 4 on the detection board 3 is provided with a bushing 7 between the detection boards, and a set screw 8 perpendicular to the slotted flat end is arranged above the bushing 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com