Novel impeller of turbine flow sensor

A turbine flow and sensor technology, applied in the field of flow sensors, can solve problems such as the deterioration of instrument linearity, achieve the effects of reducing linearity errors, improving instrument performance, and increasing instrument coefficients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The preparation method of the present invention is a conventional production preparation process,

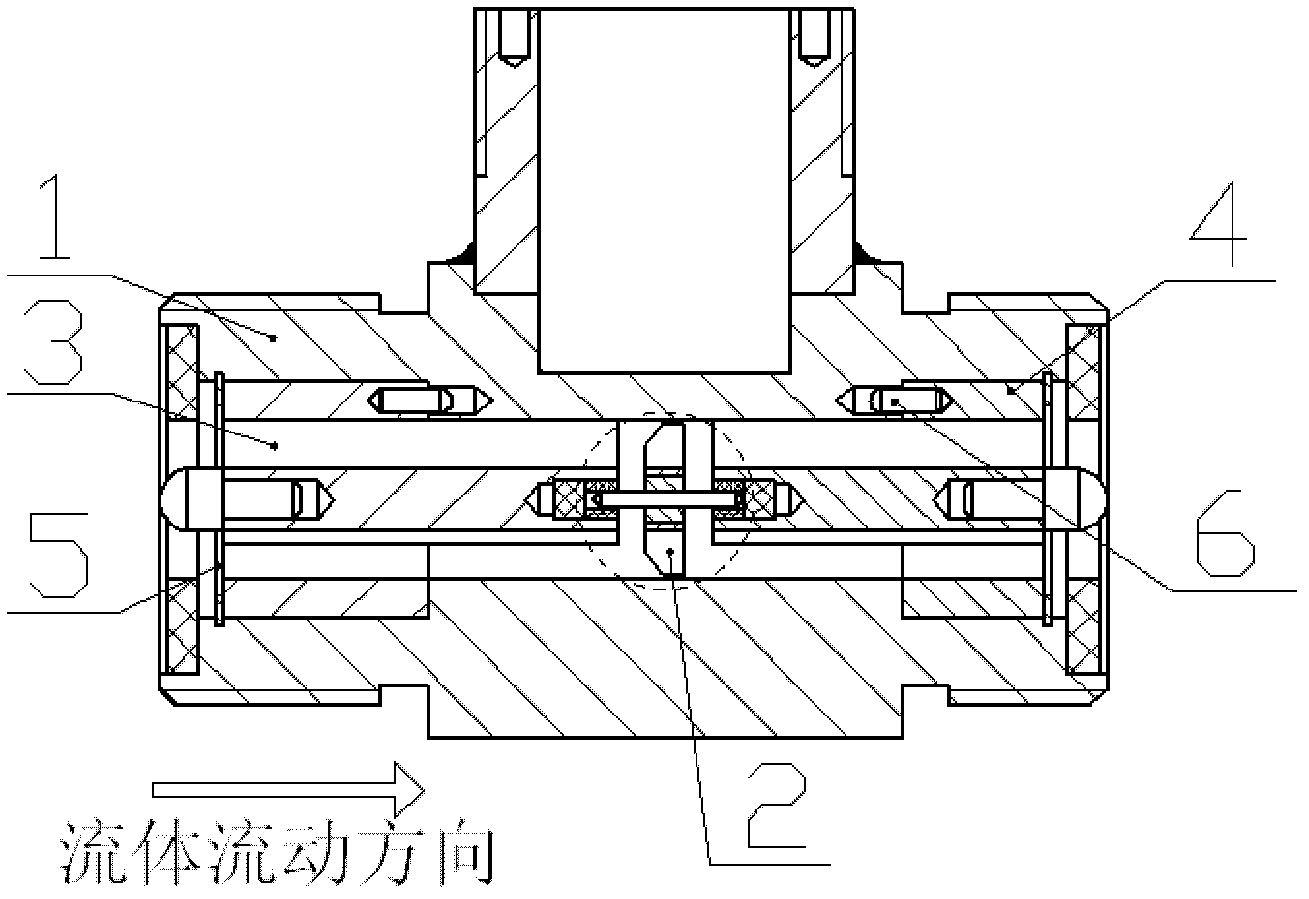

[0022] The installation position of the novel impeller of the present invention in the turbine flow sensor is as follows: figure 1 As shown, the new type of impeller 2 is supported by the front deflector 3 and the rear deflector 4 of the turbine flow sensor, placed together in the casing 1 of the turbine flow sensor, and the positions of the deflectors 3 and 4 are positioned with positioning nails 6 , and finally the deflector and the impeller are fixed in the casing 1 with the collar 5 .

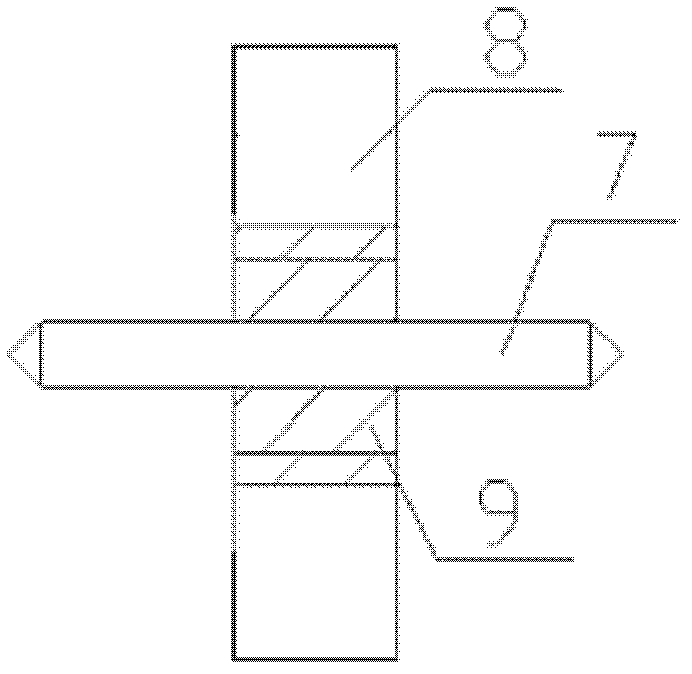

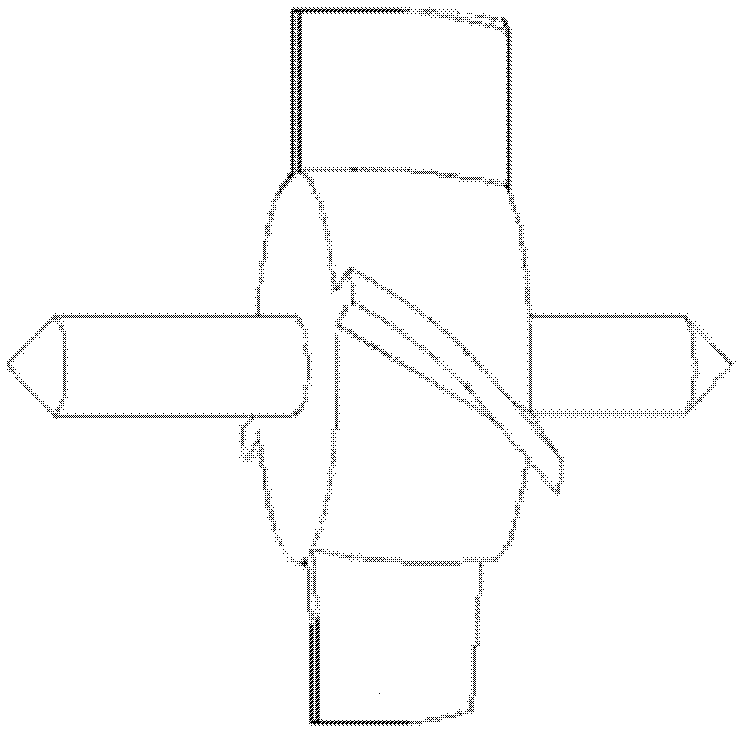

[0023] The impeller of the existing turbine flow sensor has a complete piece of blade structure, such as figure 2 , image 3 shown. An auxiliary hub 9 is arranged on the outer periphery of the impeller shaft 7, and a plurality of blades 8 are arranged along the periphery of the auxiliary hub 9, and the number of the blades 8 is determined according to actual needs.

[0024] The bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com