Detection circuit for output laser energy of laser welding machine

A laser welding machine and detection circuit technology, applied in the field of detection circuits, can solve the problems of measurement accuracy and consistency deviation, inconvenient debugging and modification, application environment temperature influence, etc., and achieves low design cost, strong versatility, strong The effect of product competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to facilitate a further understanding of the structure and achieved effects of the present invention, preferred embodiments are described in detail below in conjunction with the accompanying drawings.

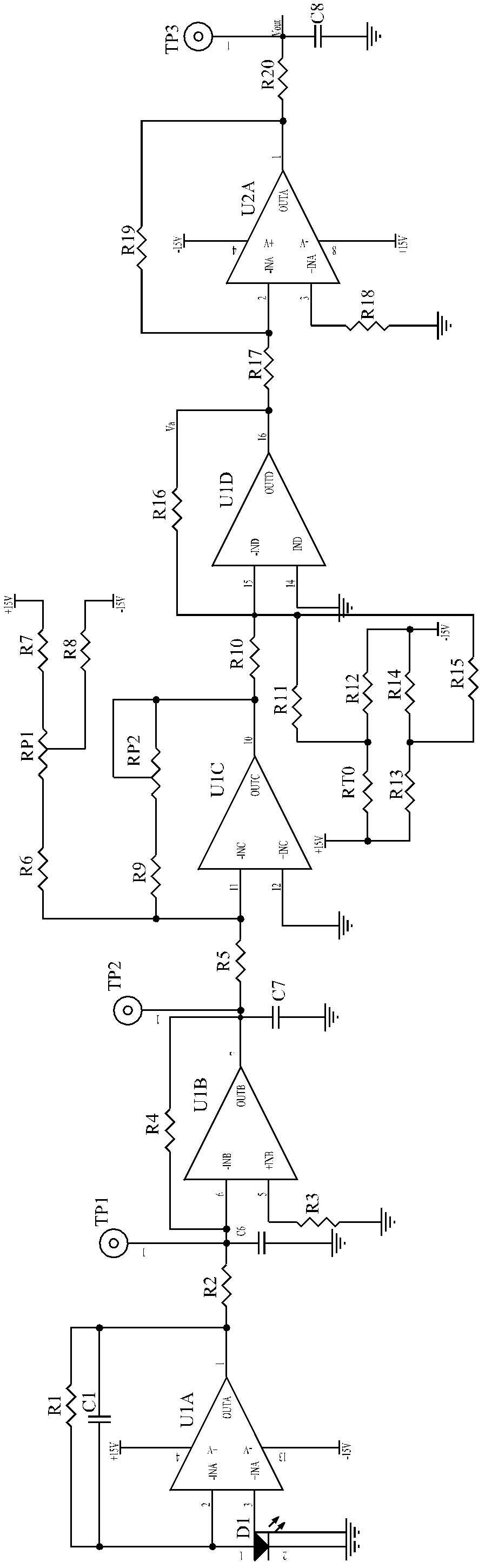

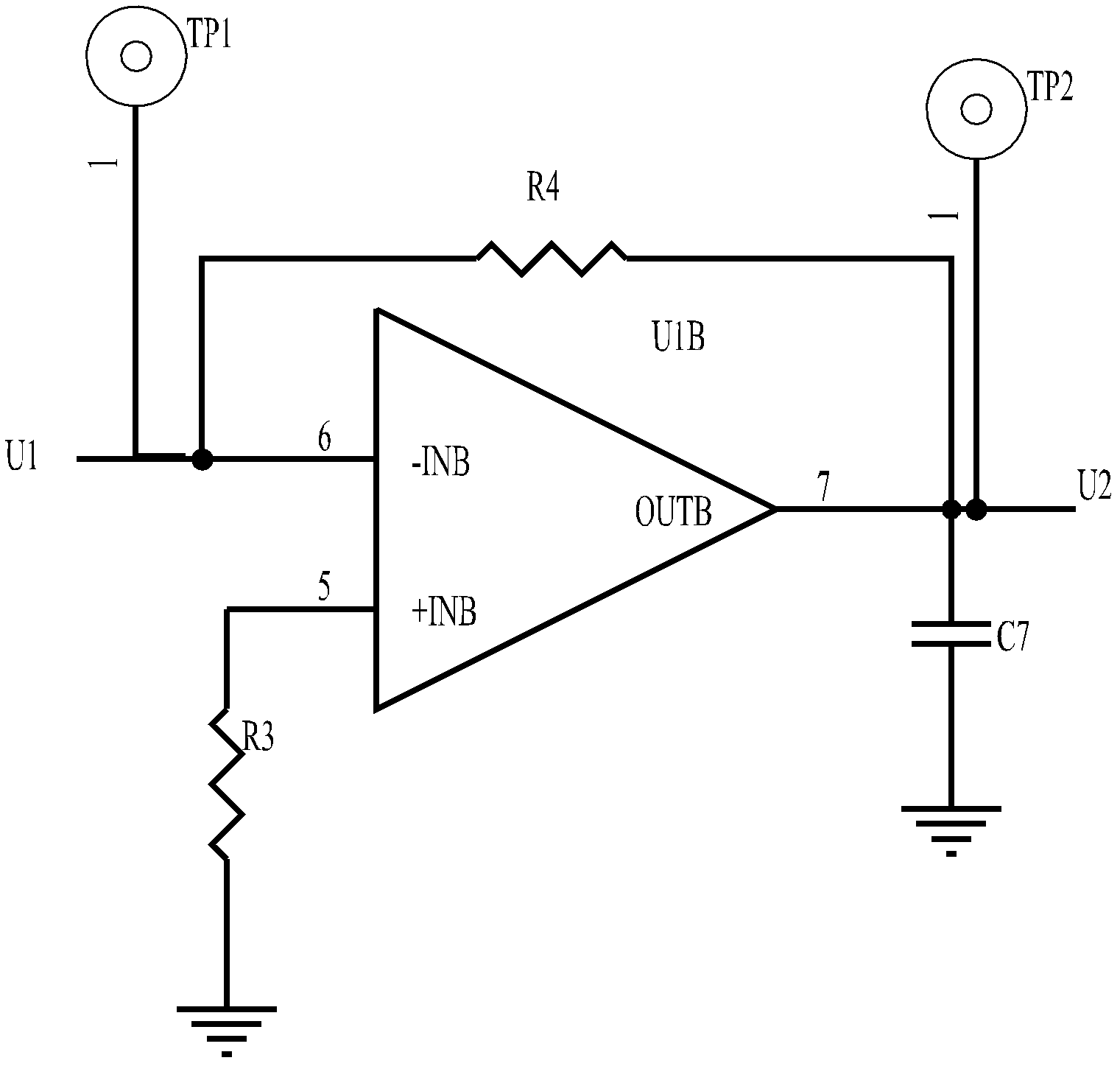

[0022] Such as figure 1 As shown, a laser welding machine output laser energy detection circuit of the present invention includes a diode primary detection circuit, an inverter circuit, a system zero adjustment and signal amplification circuit, and a temperature compensation and isolation output circuit that are electrically connected in sequence.

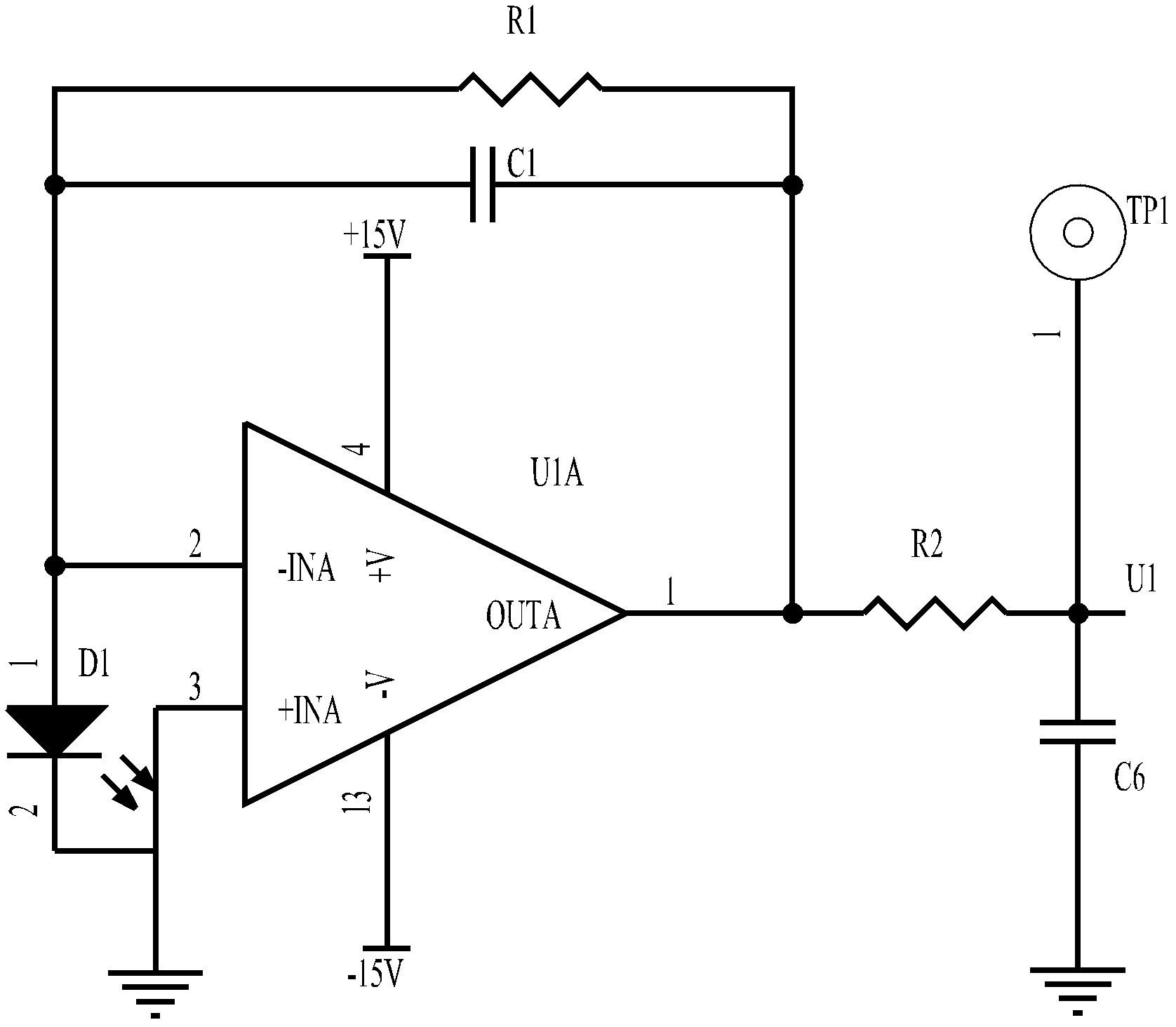

[0023] Such as figure 2 As shown, the photodiode primary detection circuit is a first-stage circuit, which serves as a sampling circuit to realize the functions of converting laser power into a current signal and converting a current signal into a voltage signal. The photodiode primary detection circuit among the present invention is made up of photodiode D1, feedback resistor R1, feedback capacitor C1, capacitor C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com