Electronic products external line water-proof structure and its assembly method

A technology for waterproof structures and electronic products, applied in the direction of sealed shells, etc., can solve the problems of high cost of waterproof structure assembly process, difficulty in large-scale production, complex structure, etc., and achieve the effect of assembly and waterproof requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

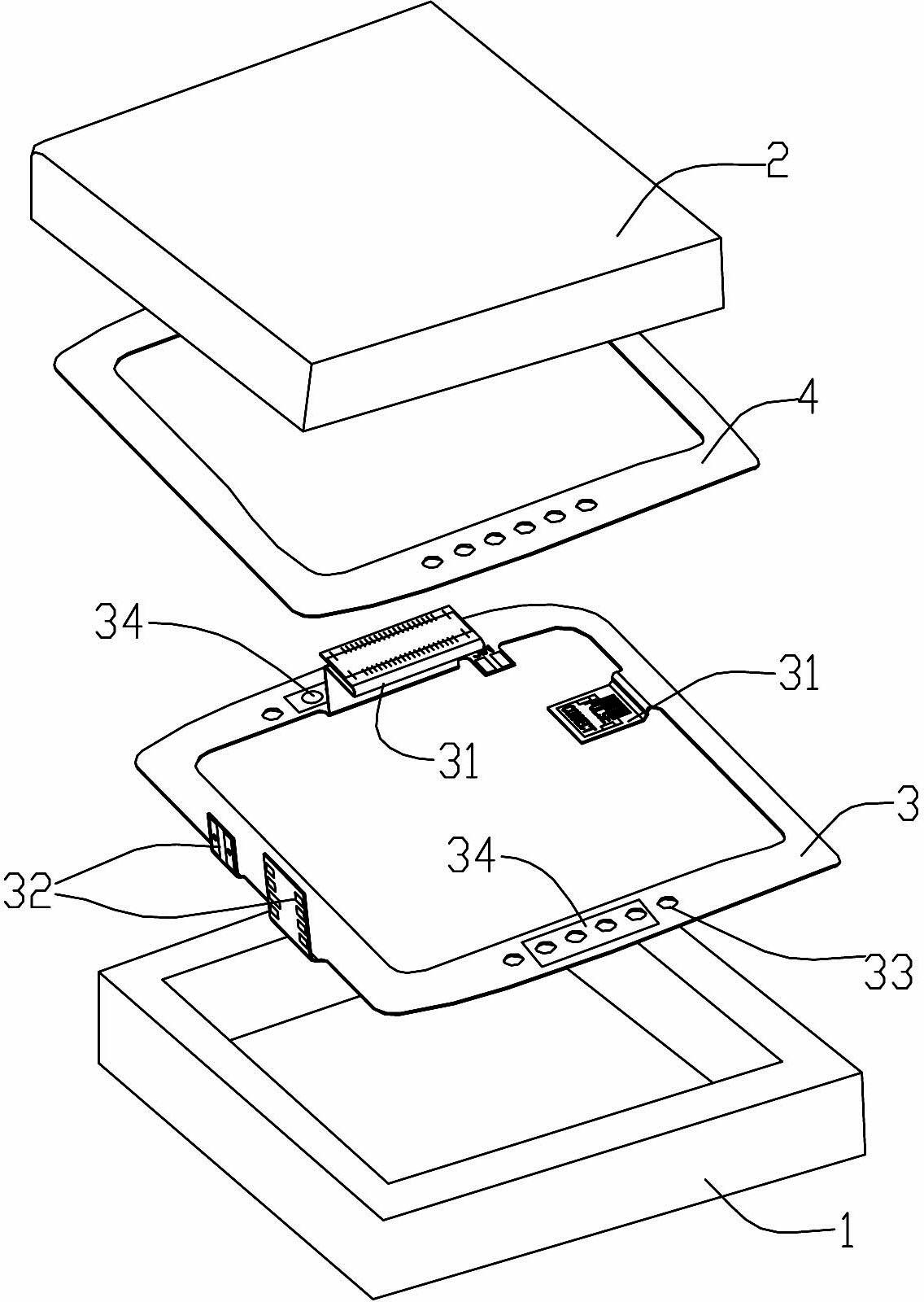

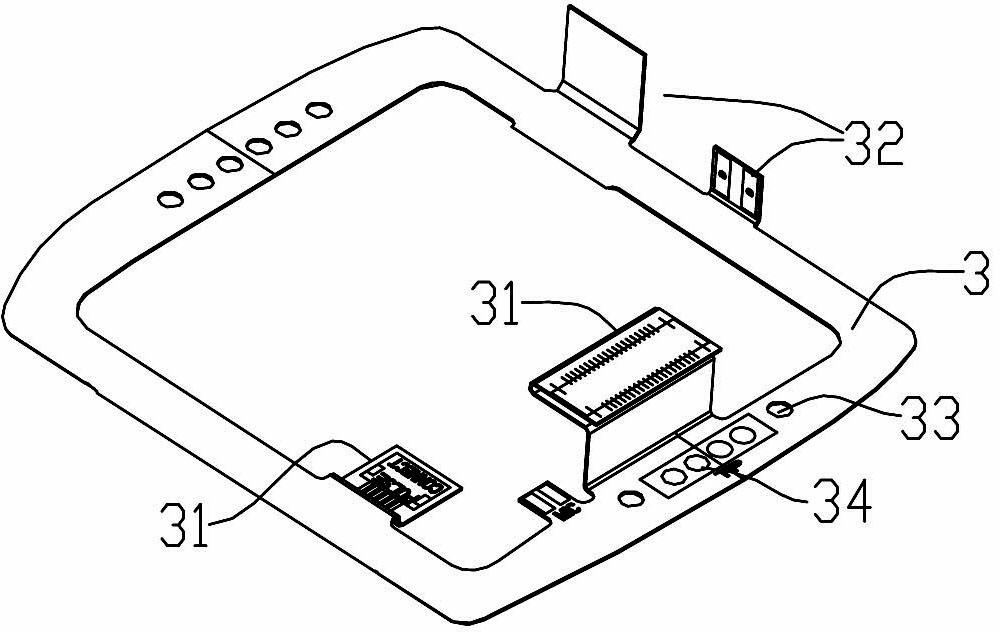

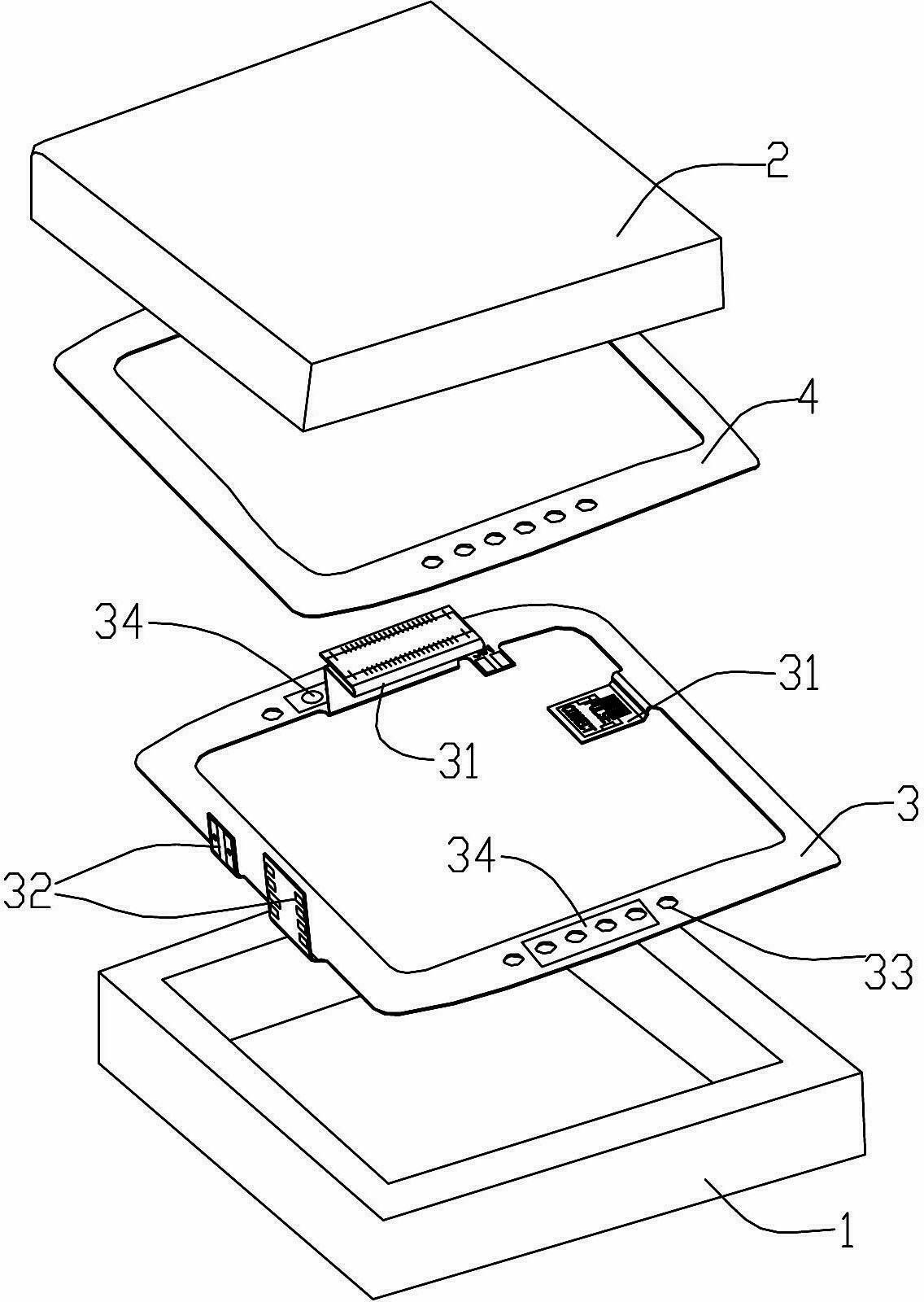

[0026] The invention as figure 1 , 2 As shown, it is a waterproof structure for external wiring of electronic products, which includes a first shell 1 and a second shell 2; the first shell 1 and the second shell 2 are joined to form a cavity for installing internal circuits .

[0027] In addition, it also includes a flexible circuit board 3, the flexible circuit board 3 is an existing FPC material circuit board, including an inner terminal 31 extending into the cavity and an outer terminal 32 extending out of the casing. The flexible printed circuit board 3 is used for circuit wiring layout, and reliably realizes the electrical connection between the internal circuit and the external circuit. interface to external circuits.

[0028] The innovation of the present invention is that the flexible circuit board 3 is used as a sealing structure between the first casing 1 and the second casing 2 . To this end, the flexible circuit board 3 must be arranged along the joint surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com