Greenhouse light replenishing device with movable light source

A technology for greenhouse and supplementary light, applied in the field of agricultural equipment, can solve the problems of high-efficiency supplementary light means and inability to obtain light, and achieve the effects of improving the supplementary light effect, saving manpower and having a simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

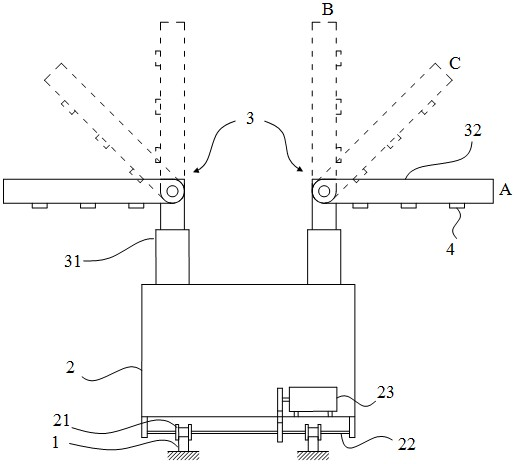

[0017] combine figure 1 , figure 2 , image 3 , Figure 4 As shown, two tracks 1 are laid on the ground of the greenhouse, two rows of four rollers 21 in total are mounted on the track 1 under the trolley 2, and the rollers 21 are installed on the front and rear drive shafts 22 and fixed on the bottom of the frame of the trolley 2 , the dolly 2 is provided with a drive motor 23 to drive the drive shaft 22 .

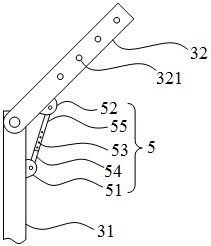

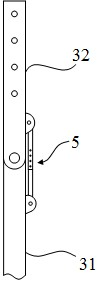

[0018] The dolly 2 is provided with two movable arms 3 that can extend upwards and sidewards. The movable arm 3 includes a telescopic arm 31 that can be adjusted up and down on the dolly 2, and a swing arm 32 that is hinged to the upper end of the telescopic arm 31 and can form a certain angle with the telescopic arm 31 and can extend outwards. 31 is hinged and has a number of pin holes 321 on both sides of the bracket 322, and the movable plate 323 in which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com