Eccentric balance weight structure of stone sawing machine transmission mechanism

A technology of transmission mechanism and eccentric counterweight, which is applied to the transmission device, gear transmission device, mechanical equipment, etc., can solve the problems of inconsistent wear of the left and right belts, large footprint of the stone saw machine, and inconvenient maintenance work, etc., so as to facilitate maintenance Maintenance work, fast stone sawing speed, simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

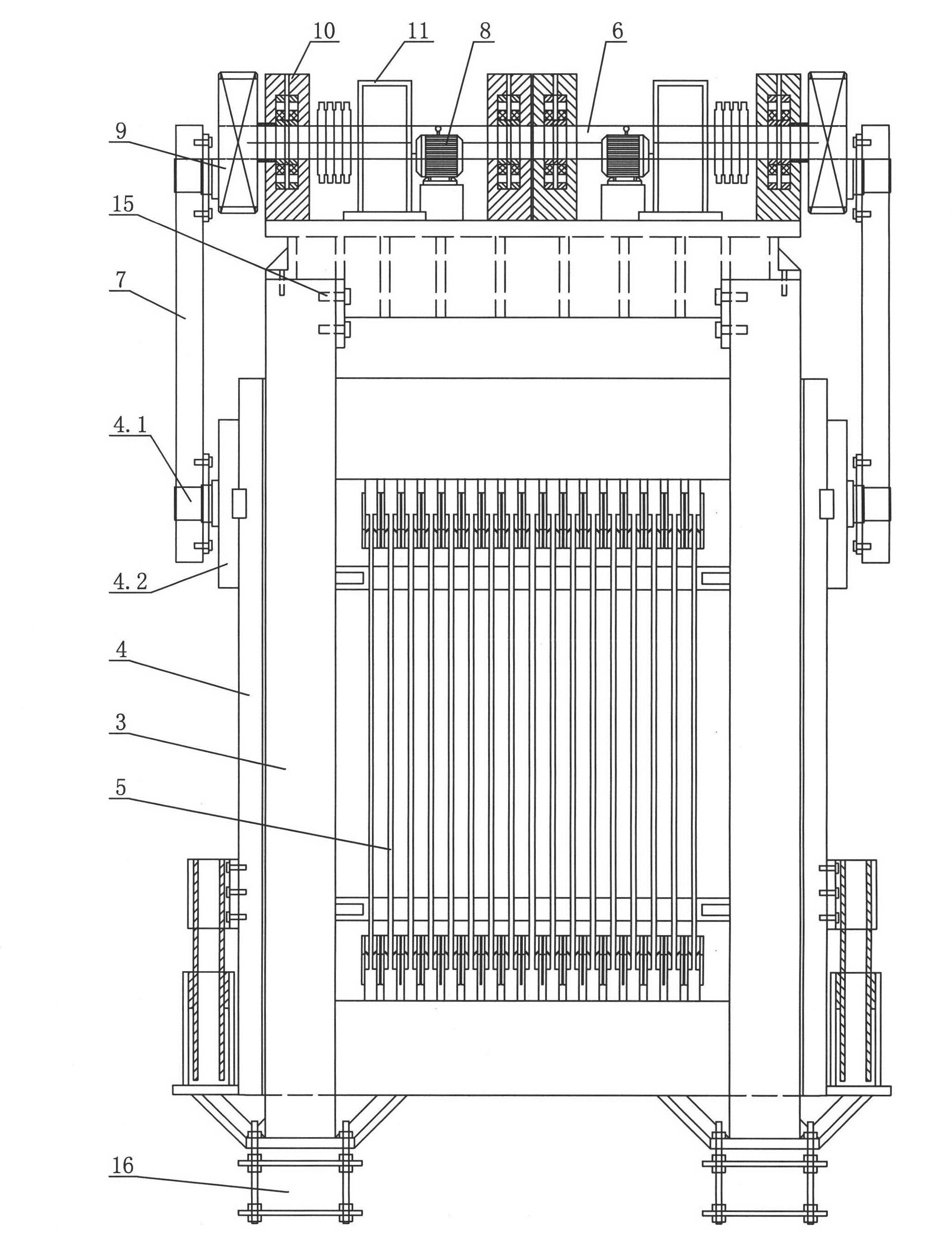

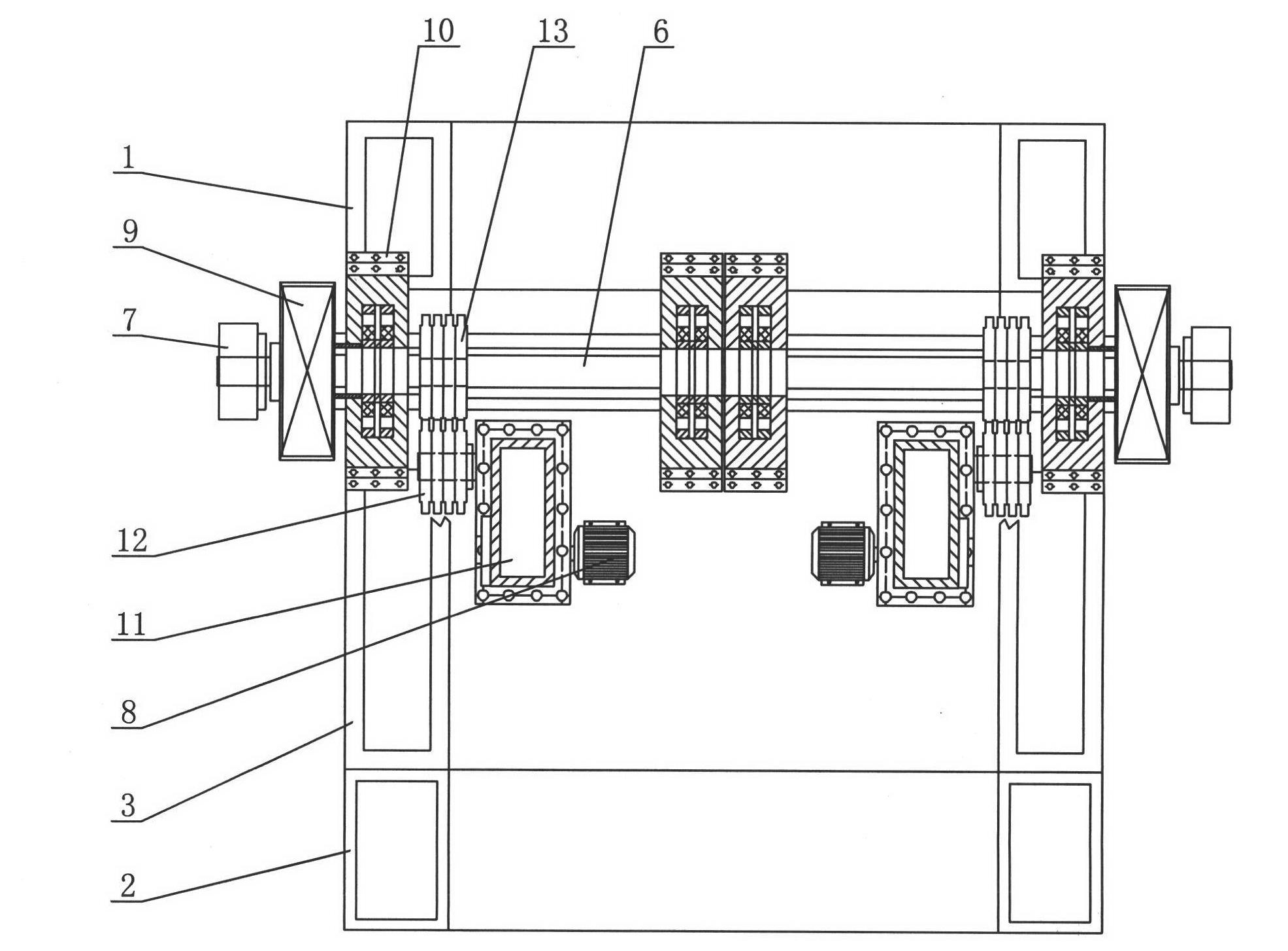

[0021] see Figure 1-Figure 6 , the eccentric counterweight structure of the transmission mechanism of the stone sawing machine includes a top frame 3 arranged between the front column 1 and the rear column 2, the saw frame 4 is located under the top frame 3, and the saw frame 4 is provided with several saw blades 5 , the top of the top frame 3 is provided with a transmission mechanism that can drive the saw frame 4 to move up and down. 4 connections.

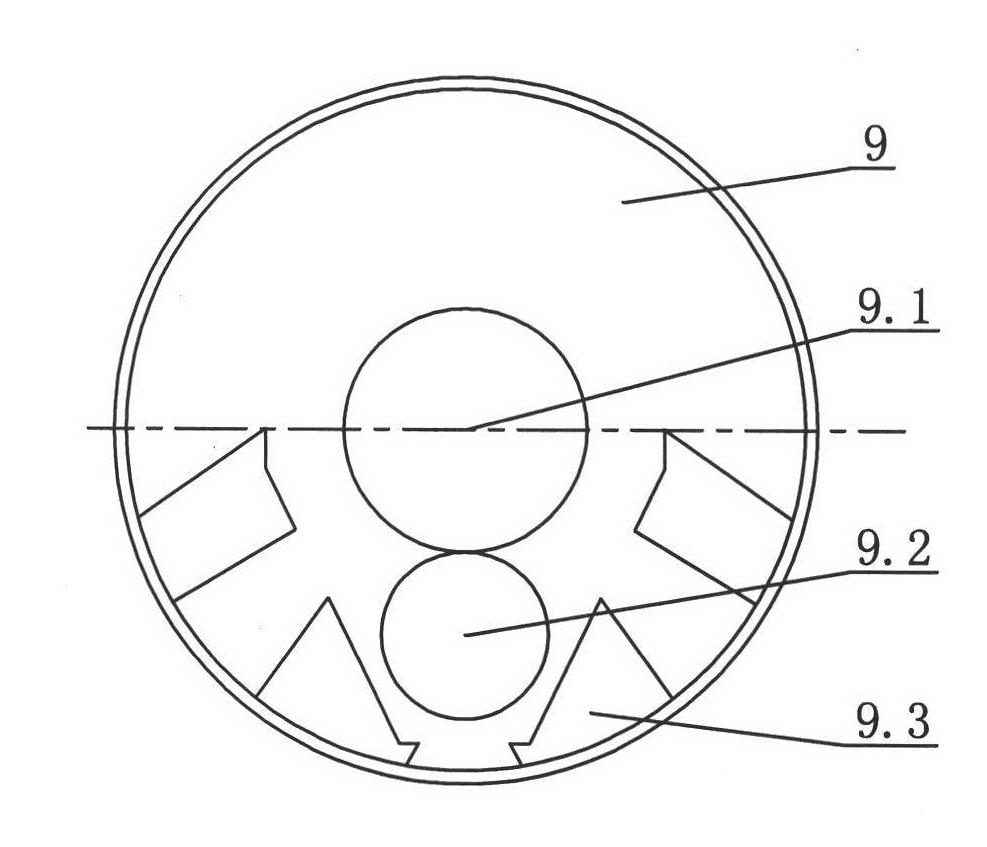

[0022] The eccentric block 9 is disc-shaped, the center of which is provided with a main shaft hole 9.1 connected with the main shaft 6, and the eccentric block 9 is provided with an eccentric shaft 9.2 adjacent to the main shaft hole 9.1. There are several counterweight holes 9.3 on the semicircle of the eccentric block 9 where the eccentric shaft 9.2 is located. In this embodiment, there are 4 counte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com