Wire harness winding machine

A winding machine and wire harness technology, which is applied in the field of wire harness winding tape, can solve the problems of the consistency and uniformity of the winding tape, the inconvenience of winding the tape, and the labor intensity of the workers, so as to save labor, have strong practicability, and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

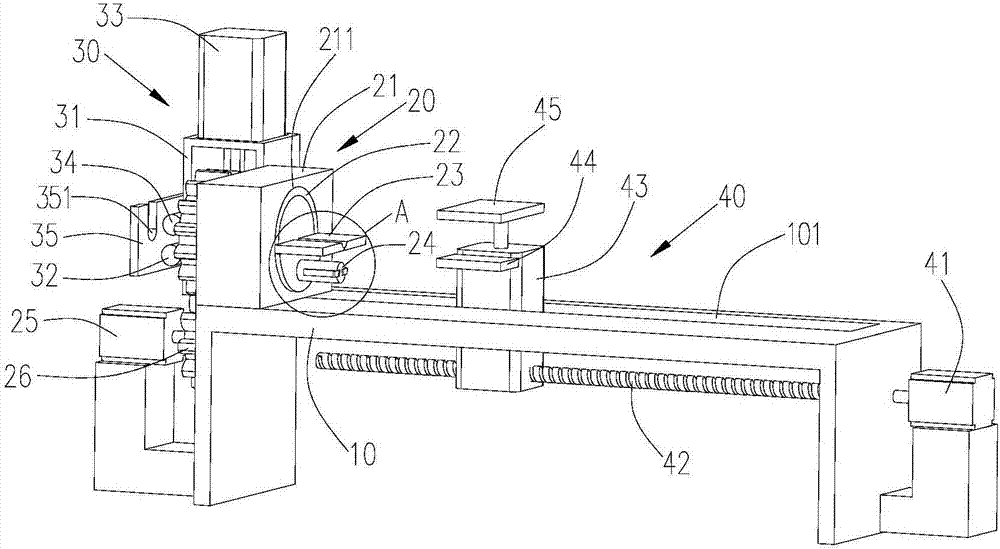

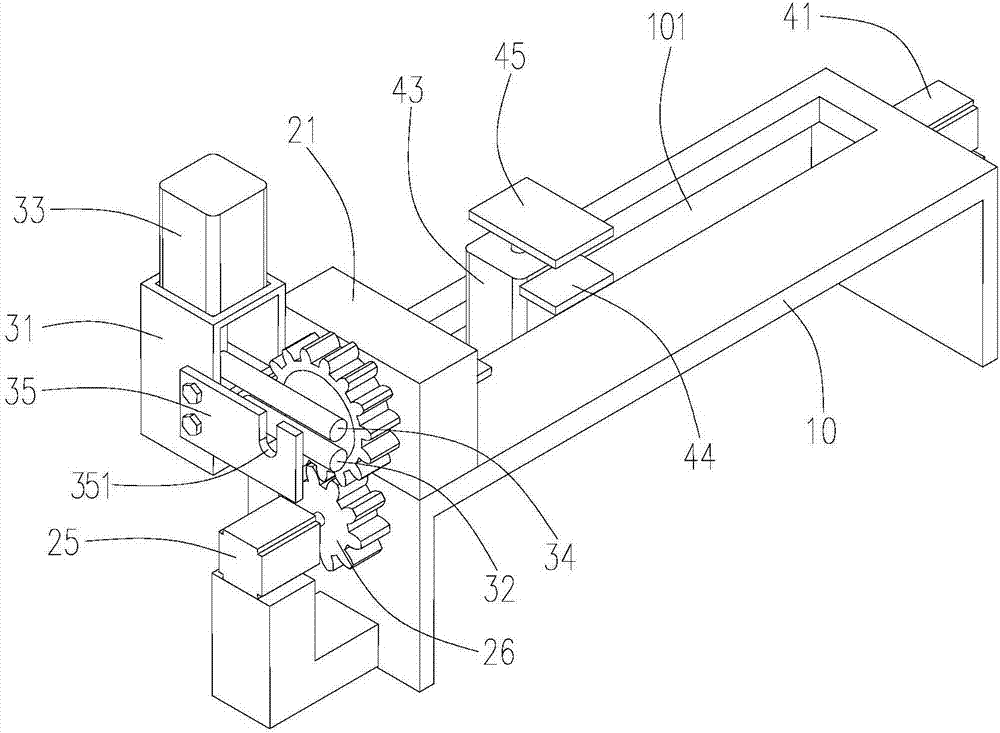

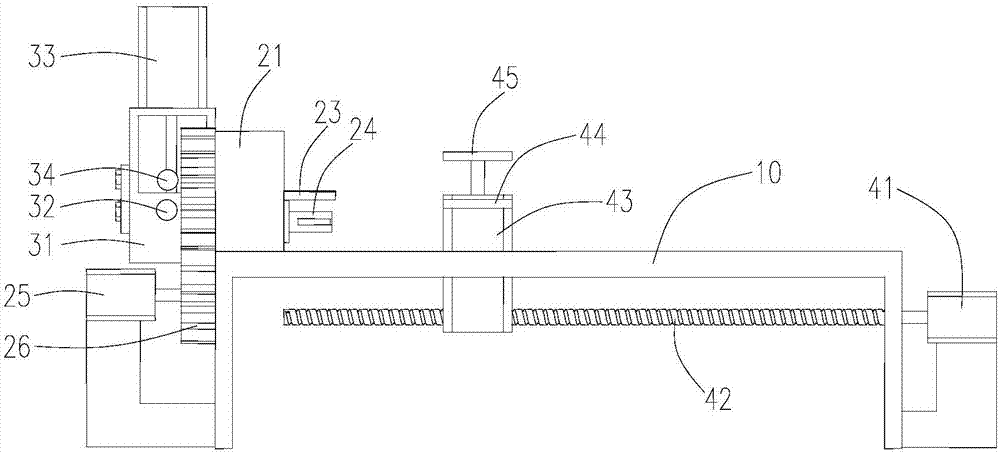

[0022] The present invention will be described in detail in conjunction with accompanying drawing now. This figure is a simplified schematic diagram only illustrating the basic structure of the present invention in a schematic manner, so it only shows the components relevant to the present invention.

[0023] Please also see Figure 1-Figure 3 , the present invention provides a wire harness winding machine. The wire harness winding machine of the present invention is used to wrap a layer of adhesive tape with waterproof performance on the surface of the wire harness. It can be understood that the use of the wire harness winding machine of the present invention is not limited to online The surface of the bundle is covered with a layer of adhesive tape, which can also be used to cover the surface of the wire harness to form an insulating layer with an insulating function or a wear-resistant layer with wear resistance.

[0024] The wire harness winding machine of the present inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com