Motor vehicle body and automobile with the motor vehicle body

A technology for automobile bodies and vehicles, applied to vehicle parts, upper structure sub-assemblies, lower structures, etc., can solve problems such as increasing vehicle weight and increasing production costs, and achieve the effect of improving structural rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

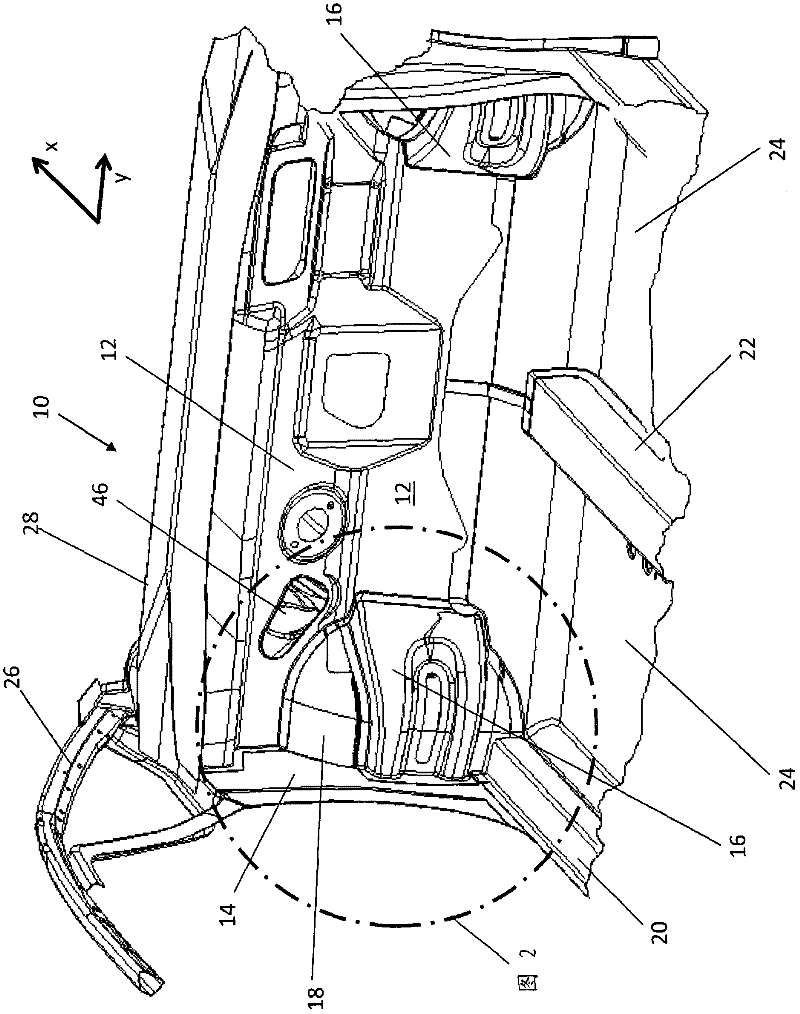

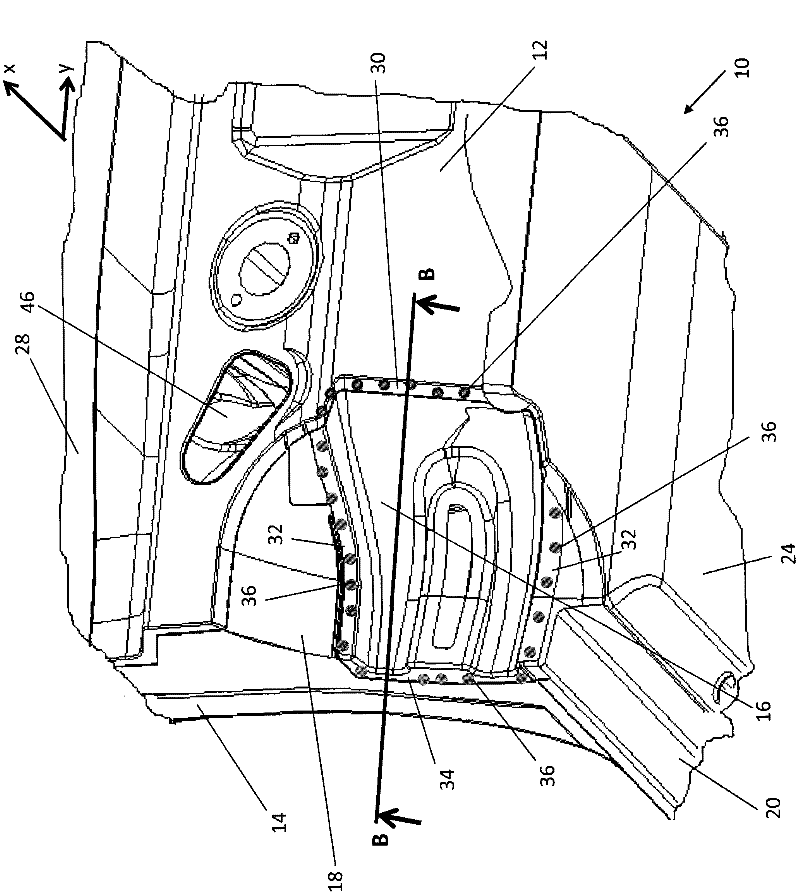

[0039] figure 1 and figure 2 Shown is a vehicle bodywork cowl structure 10 viewed from the vehicle interior. The bulkhead structure 10 has a bulkhead 12 which extends between two wheelhouse parts 18 which are each laterally raised inwardly. A bottom plate 24 and a middle bottom groove 22 are provided adjacent to the dash panel 12 facing downward.

[0040] The inner skirt 20 extends adjacent to the bulkhead 12 and adjacent to the floor panel 24 in the vehicle longitudinal direction (x) opposite to the forward direction of the vehicle. also figure 1 Shown are the side bulkhead panels 14 as well as the A-pillars 26 and glass brackets 28 for the windshield. The dash panel 12 also has a steering channel 46 for receiving a steering column.

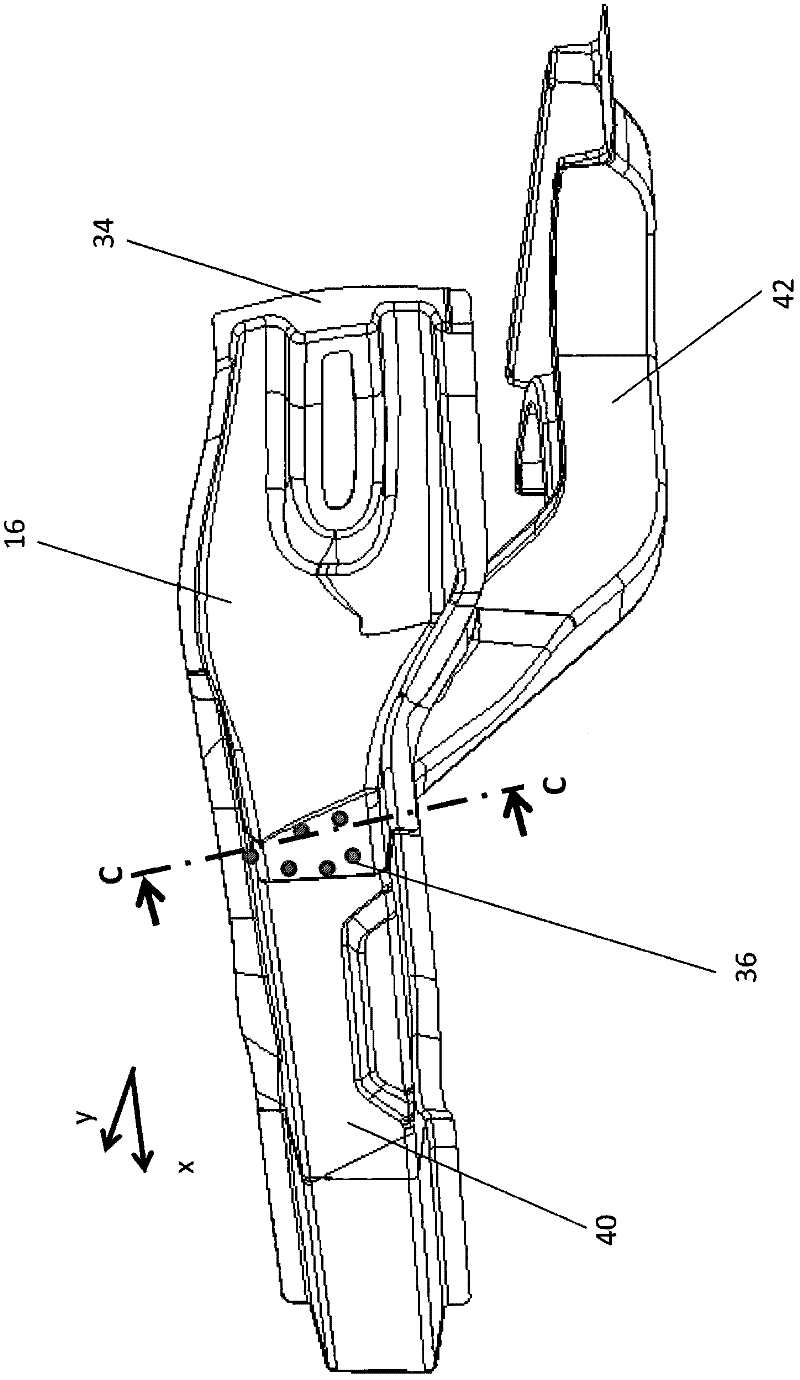

[0041] A reinforcement 16 facing the interior of the passenger compartment is provided in the region of the inwardly raised wheelhouse panel 18 , which can be formed in one piece with the bulkheads 12 , 14 , for example above the fastening...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com