Engine material frame

A technology for engines and material racks, which is applied in the field of material racks for placing engines to achieve the effects of ensuring transportation safety, reducing labor intensity, and improving transportation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

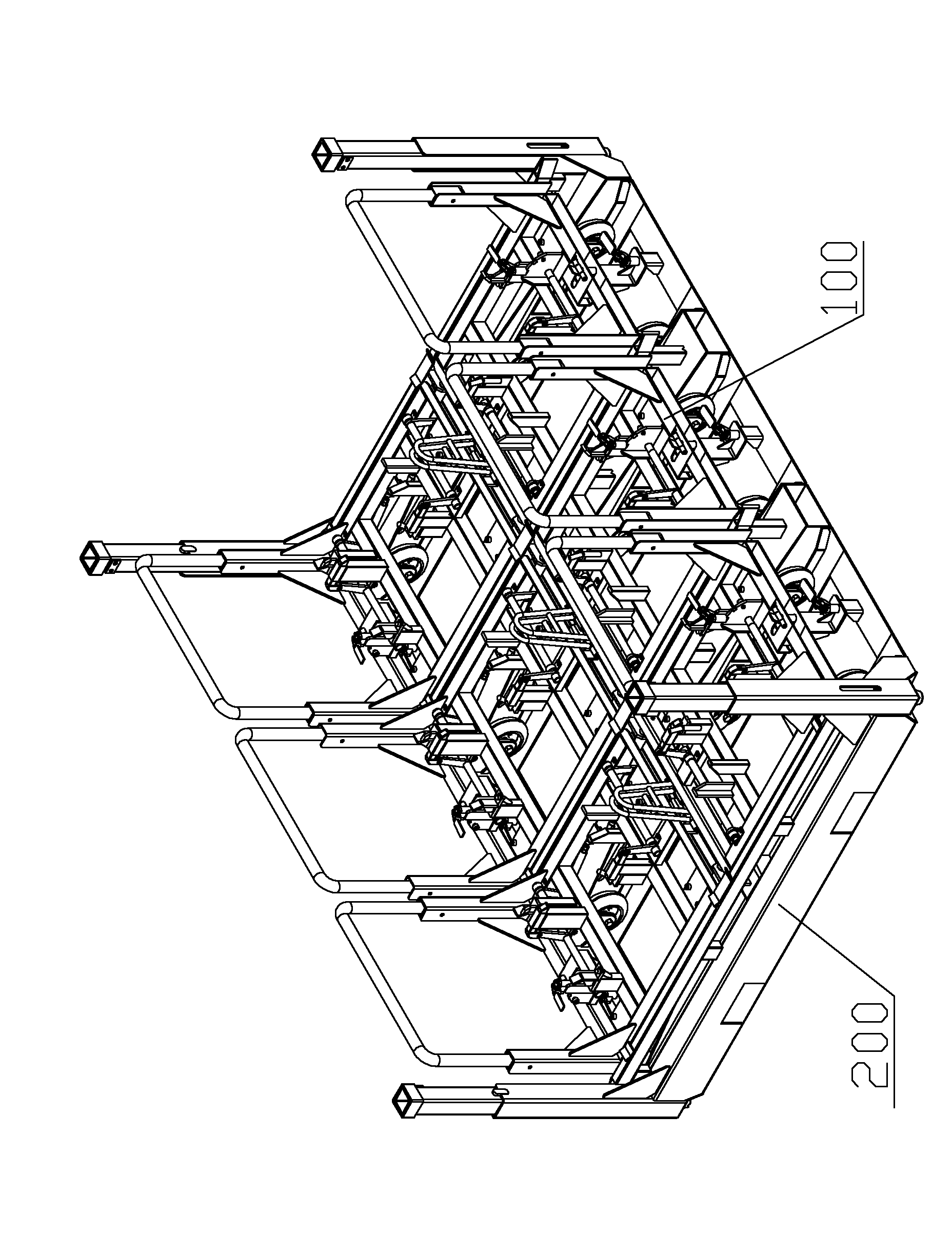

[0041] figure 2 It shows the structure of the engine rack in this embodiment according to the present invention. Such as figure 2 As shown, the engine material rack in this embodiment has an engine material rack assembly, and the engine material rack assembly includes a bottom frame 200 and six material rack trolleys 100 . Six rack trolley stations are arranged on the underframe 200 , and the six rack trolleys 100 are divided into two rows, which are respectively symmetrically arranged in the rack trolley stations of the underframe 200 .

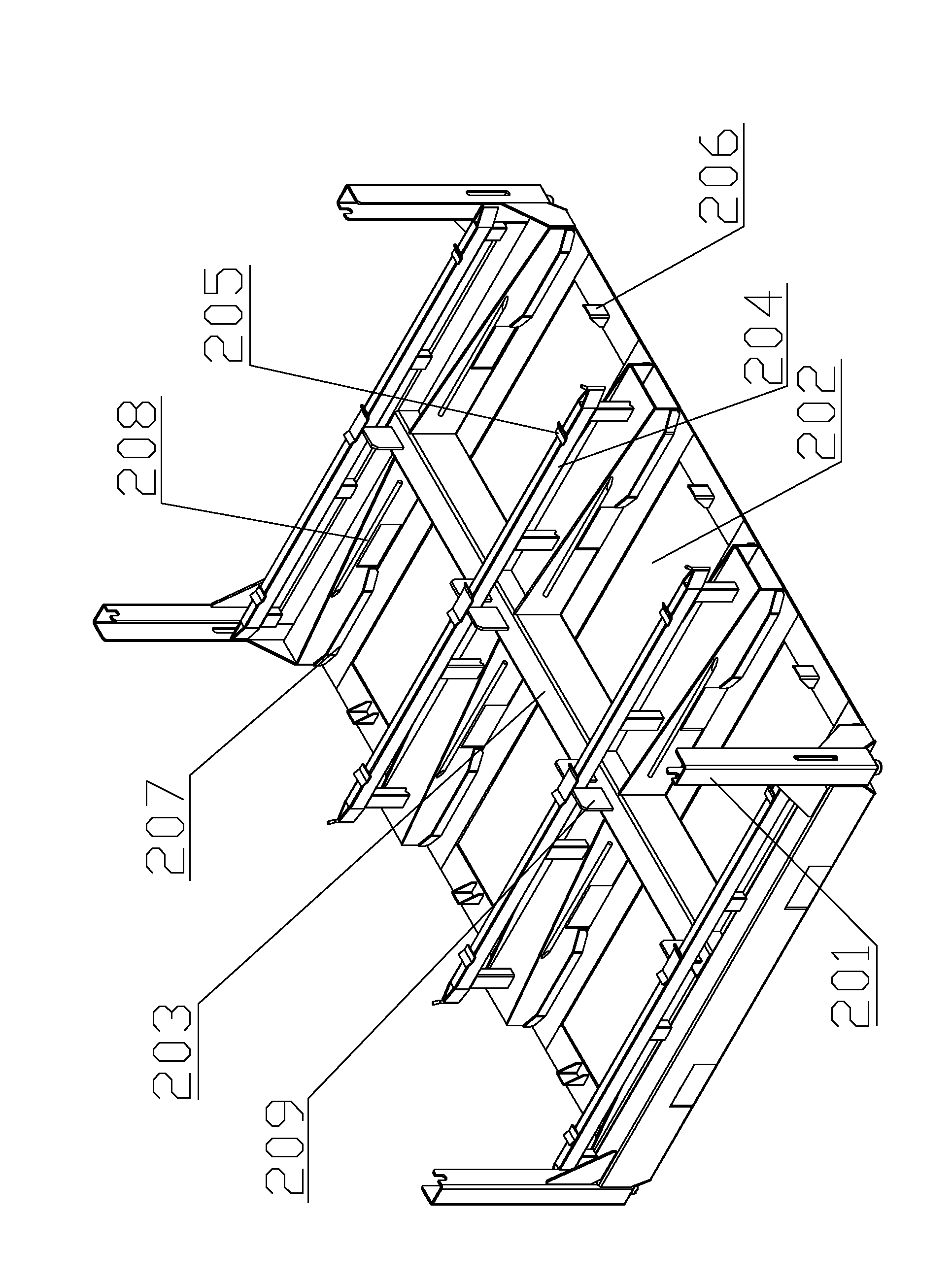

[0042] image 3 The structure of the underframe in one embodiment of the engine rack according to the present invention is shown. Such as image 3 As shown, the underframe is a quadrilateral frame structure, and the six rack trolley stations 202 are divided into two rows, and are symmetrically arranged on the underframe with the beam 203 as the axis of symmetry, and each rack trolley station 202 has an inlet port and In the closed end...

Embodiment 2

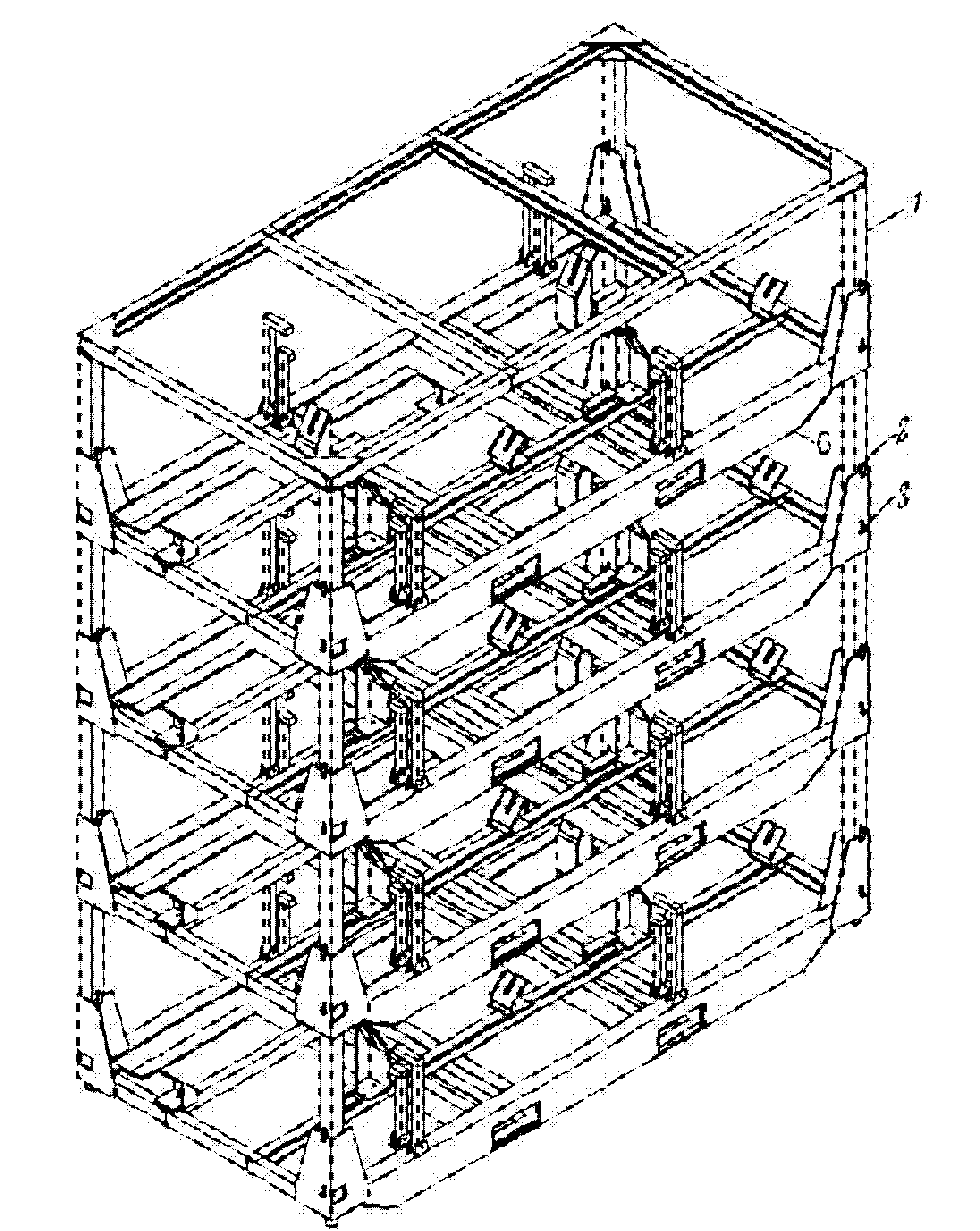

[0052] Figure 7 It shows the structure of the engine rack in this embodiment according to the present invention. Such as Figure 7 As shown, the engine material rack in this embodiment has two engine material rack assemblies as described in Embodiment 1, and is stacked through the upright column at the vertical station on the bottom frame, thereby saving the engine material rack. Space. The structure of the engine rack assembly in this embodiment is the same as that of the engine rack assembly in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com