Emergency treatment method for refined vinyl acetate

A technology of refined vinyl acetate and vinyl acetate, which is applied in the field of chemical safety, can solve problems such as accidents, major production safety responsibilities, explosions, etc., and achieve the effect of preventing violent polymerization accidents and eliminating the risk of violent polymerization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

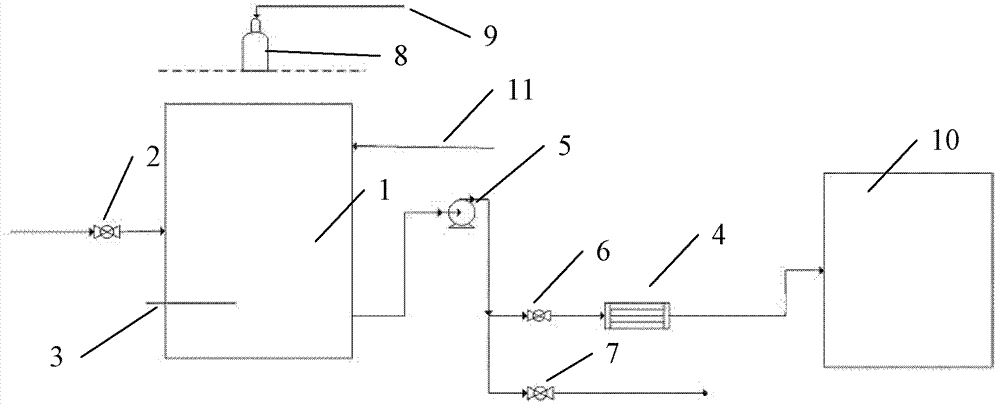

[0061] The vinyl acetate storage device of the present invention comprises a vinyl acetate storage tank 1, a vinyl acetate material feed valve 2 arranged on the vinyl acetate storage tank, a thermometer 3 arranged on the vinyl acetate storage tank, a cooler 4, an outlet Material pump 5, emergency discharge valve 6, discharge valve 7, material feed pipeline, discharge pipeline, spray water device and spare storage tank 10 composed of spray head 8 and water supply pipeline 9, the material The feed valve 2 is connected to the vinyl acetate storage tank 1 through the material feed pipeline, one end of the discharge pump 5 is connected to the vinyl acetate storage tank 1 through the discharge pipeline, and the other end is connected to the vinyl acetate storage tank 1 through the discharge pipe. One branch of the pipeline is connected with the emergency discharge valve 6, the other branch of the discharge pipeline is connected with the discharge valve 7, and the emergency discharge ...

Embodiment 2

[0063] Refined vinyl acetate material is housed in the vinyl acetate storage tank in the vinyl acetate storage device in embodiment 1, determines that this refined vinyl acetate reaches the required time TMRad=24h of maximum reaction rate under adiabatic condition, judges the refined vinyl acetate In the state of existence, when the purified vinyl acetate is in a dynamic state, its emergency treatment temperature is set at 57.5°C. The temperature of the refined vinyl acetate material in the vinyl acetate storage tank is measured in real time by the thermometer 3 provided on the refined vinyl acetate storage tank 1; when the temperature of the refined vinyl acetate material in the storage tank reaches the emergency treatment temperature of 57.5°C, Close the refined vinyl acetate material feed valve 2, cut off the feed, open the polymerization inhibitor feed valve at the same time, add a large amount of polymerization inhibitor hydroquinone in the vinyl acetate storage tank 1, an...

Embodiment 3

[0065]In the vinyl acetate storage tank 1 in the vinyl acetate storage device in embodiment 1, the refined vinyl acetate material is housed, and the time TMRad=24h that this refined vinyl acetate reaches the maximum reaction rate required under adiabatic conditions is determined, and the refined vinyl acetate is judged In the state of existence of refined vinyl acetate in a static state, when the initial storage temperature of the refined vinyl acetate material stored in the storage tank is detected by the thermometer 3 on the vinyl acetate storage tank 1 at 20°C, the emergency treatment temperature Set to 43.5°C. The temperature of the refined vinyl acetate material in the vinyl acetate storage tank 1 is measured in real time by the thermometer 3 installed on the refined vinyl acetate storage tank; when the temperature of the refined vinyl acetate material in the storage tank reaches the emergency treatment temperature of 43.5°C, Close the refined vinyl acetate material feed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com