Anti-freezing concrete water reducer

A technology of concrete water reducing agent and water reducing agent, which is applied in the field of concrete admixture, which can solve the problems of rising production cost, increasing the amount of antifreeze, and increasing water demand, and achieve the effects of reducing water demand, lowering freezing point, and promoting hydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

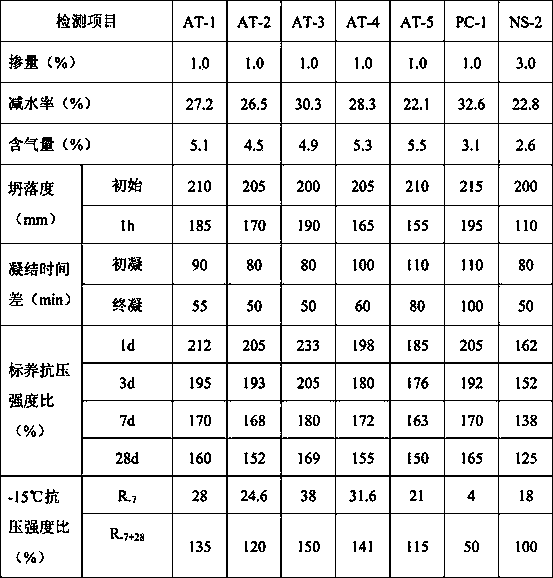

Examples

Embodiment 1

[0032] Weigh 49.80kg of water and put it in the reaction kettle, then add 10.00kg of sodium nitrite under stirring state, and add 40.00kg of 40% solid content polycarboxylate superplasticizer (VIVID-500 (D type) after it is completely dissolved. The average molecular weight is 31200, produced by Shanghai Sanrui Polymer Material Co., Ltd.), then add 0.20kg of lauryl alcohol ether AS-2, and continue to stir evenly to obtain the water reducer of the present invention, which is recorded as AT-1.

Embodiment 2

[0034] Weigh 53.80kg of water and put it in the reaction kettle, then add 8.00kg of sodium nitrite, 2.00kg of sodium nitrate and 2.00kg of sodium sulfate successively under stirring, and add 2.00kg of sodium gluconate after the inorganic salt is completely dissolved, and then add 32.00kg 40% solid content polycarboxylate superplasticizer (VIVID-500 (D type), weight average molecular weight 31200, produced by Shanghai Sanrui Polymer Material Co., Ltd.), then add 0.20kg lauryl alcohol ether AS- 2. After continuing to stir evenly, the water reducer of the present invention is obtained, which is designated as AT-2.

Embodiment 3

[0036] Weigh 43.80kg of water and put it in the reaction kettle, then add 12.00kg of sodium nitrite, 2.00kg of sodium sulfate and 5.00kg of calcium nitrite successively under stirring, and add 3.00kg of sodium gluconate after the inorganic salt is completely dissolved, and then Add 48.00kg of 40% solid content polycarboxylate superplasticizer (VIVID-500 (D type), weight average molecular weight 31200, produced by Shanghai Sanrui Polymer Material Co., Ltd.), and then add 0.10kg of lauryl alcohol ether AS -2. After continuing to stir evenly, the water reducer of the present invention is obtained, which is designated as AT-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com