Method for heating and supporting aluminum band

An aluminum strip and supporting force technology, applied in heat treatment furnaces, heat treatment equipment, furnace types, etc., can solve the problems of complex furnace structure, large furnace width and poor running stability of aluminum strips, and achieves favorable floating stability and compact design structure. , to ensure the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The content of the present invention will be further clarified below in conjunction with the embodiments and accompanying drawings, but the content of the present invention is not limited to the following embodiments.

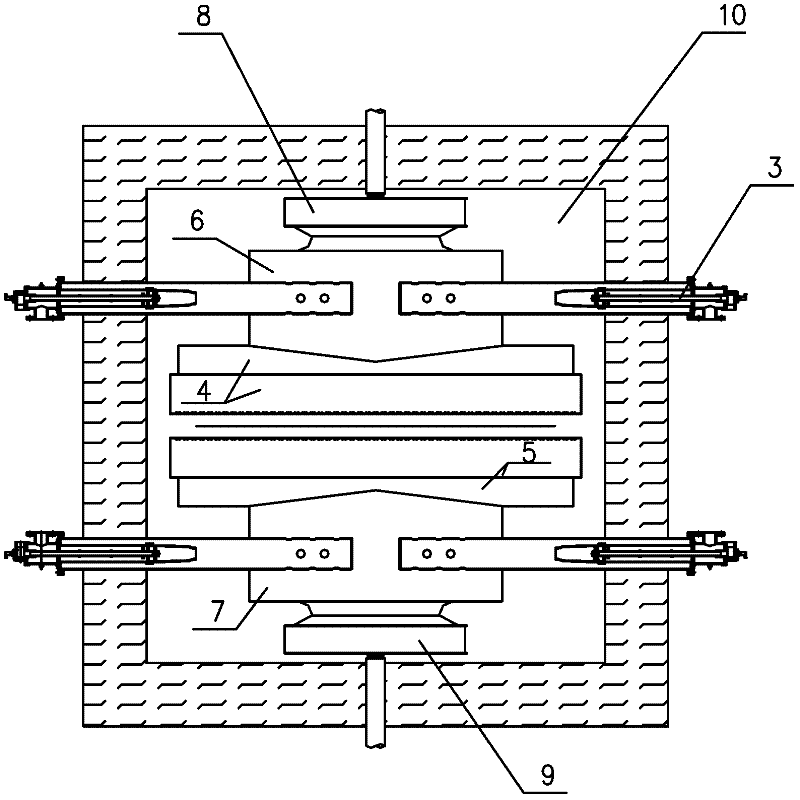

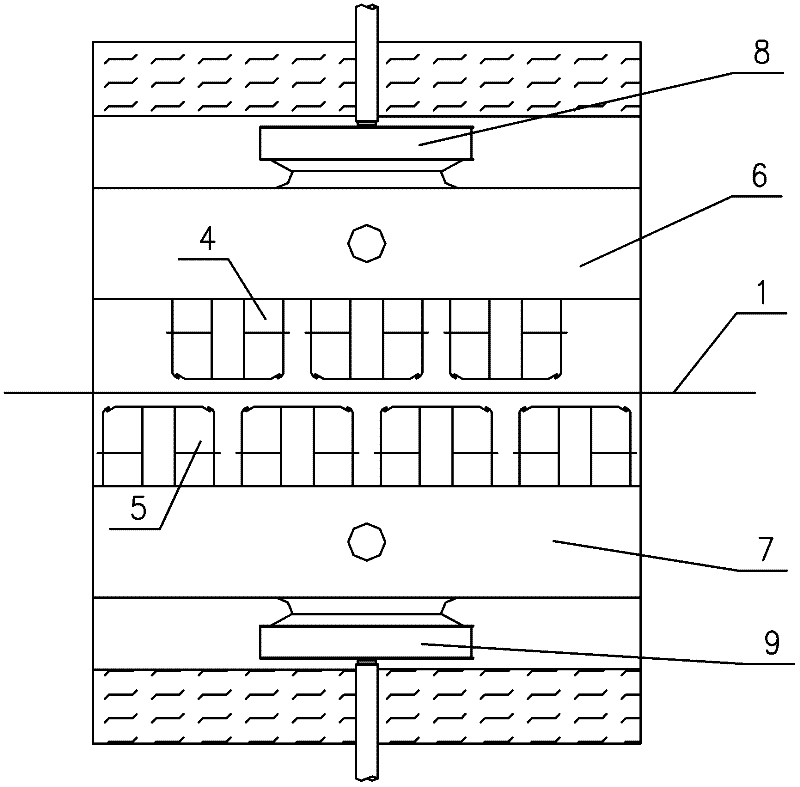

[0032] The method for heating and supporting the aluminum strip provided by the present invention uses the circulation fan as the source power, the heating system as the supplementary heat source, and continuously floats and heats the aluminum strip through the spray box to realize the heating and supporting of the aluminum strip. support. details as follows:

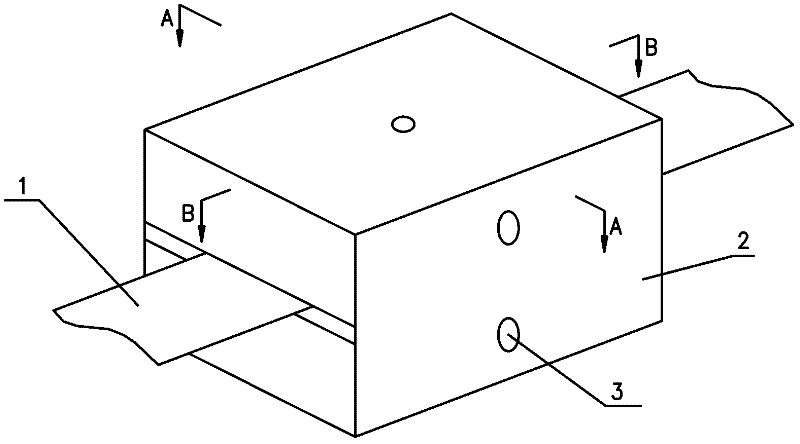

[0033] The method for heating and supporting the aluminum strip provided by the present invention is realized by using an aluminum strip heating and supporting device mainly composed of a furnace body, a heating device, an air cushion group, a gas collection chamber and a circulating fan, wherein: the air cushion group 1. The gas collection chamber and the circulation fan are located inside the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com