An axial positioning device

A technology of axial positioning and bearing bush, applied in the direction of bearing components, shafts and bearings, rigid brackets of bearing components, etc., to achieve the effect of convenient installation, replacement and maintenance, high reliability, and easy installation, replacement and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

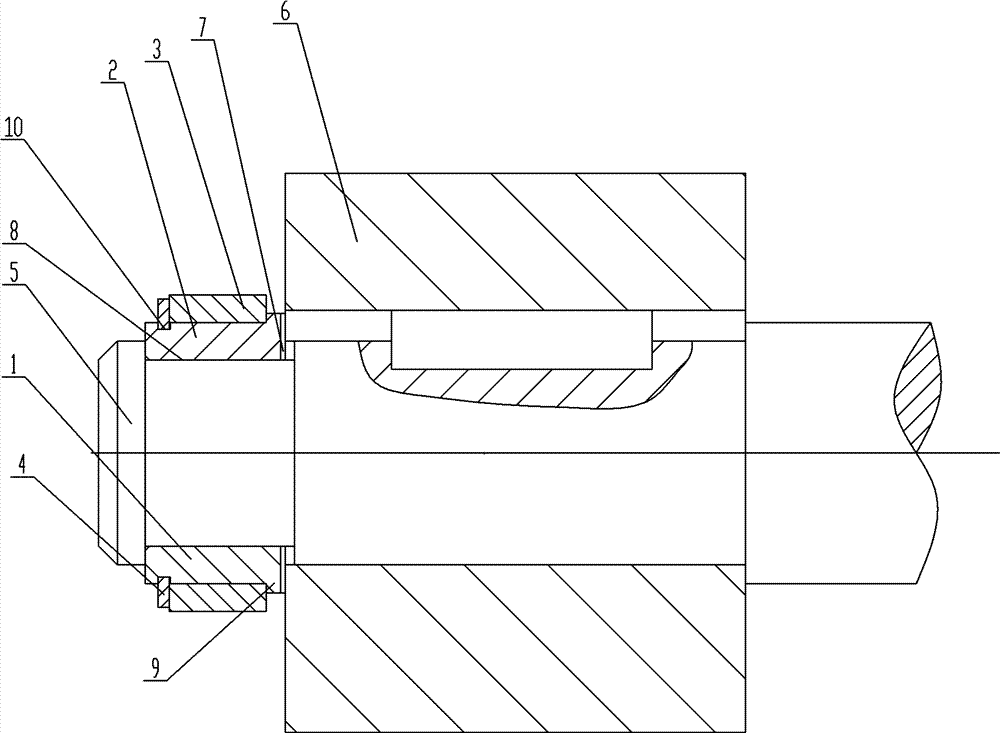

[0018] The structure of the rotor axial positioning device of the present invention is shown in figure 1 , including half bearing bush 1, half bearing bush 2, collar 3, shaft circlip 4, shaft 5, rotor 6, gasket 7; two half bearing bushes 1, 2 are embedded in the annular groove on the shaft 5 to bear the axial Gasket 7 is used to adjust the gap between the bearing bush and the end face of the rotor; the collar 3 is set outside the two half bearing bushes 1 and 2 to fix the bearing bush and bear the radial force that the bearing bush may generate; the shaft circlip 4 is installed on the two half bearing bushes The collar 3 is axially fixed in the groove on the half bearing bush.

[0019] The two half-bearing bushes 1 and 2 are made of stainless steel or non-metallic materials, and after each size is processed together, they are separated into two halves, marked with the same marks respectively and stored in pairs. Ensure that the axial dimensions of the grooves into which the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com