Ultrasonic levitation and air floatation mixed suspension damping device

A suspension device, ultrasonic technology, applied in the direction of shock absorber, shock absorber-spring combination, shock absorber, etc., to achieve the effect of simple structure, small low-frequency vibration reduction, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

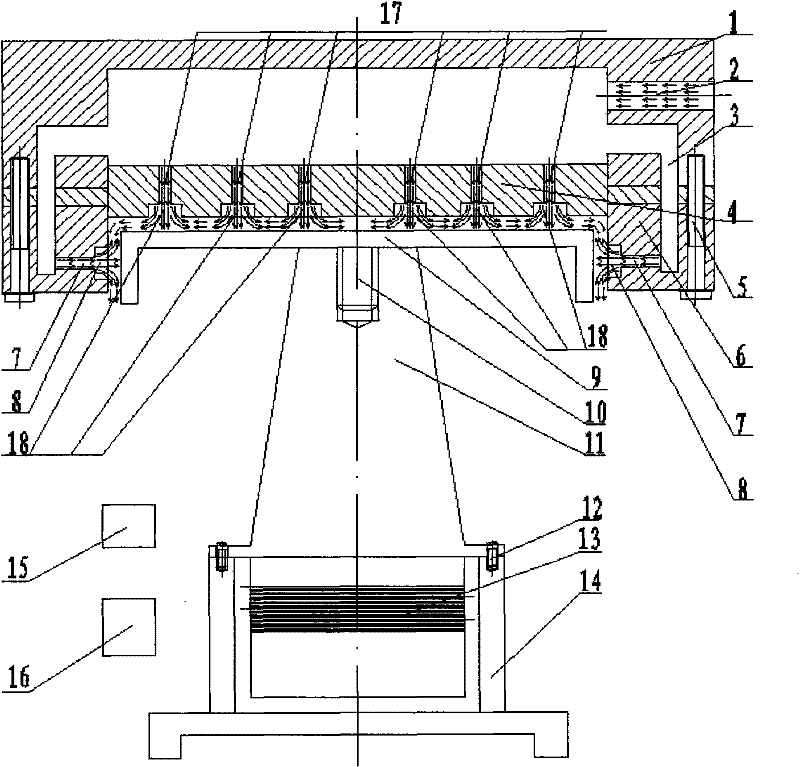

[0030] see image 3 , the air bearing (4) is fixed together with the working platform (1) and the platform base (6) by bolts (5). Ultrasonic transducer (11) is fixedly connected by screw (10) ultrasonic transducer disk (9). The ultrasonic transducer (11) is fixedly connected with the instrument support (14) through screws (12). The ultrasonic transducer (11) is connected with the ultrasonic signal generator (15). The air bearing (4) is placed on the ultrasonic transducer disk (9). The gas that air compressor (16) comes out enters air inlet (2) after filtering.

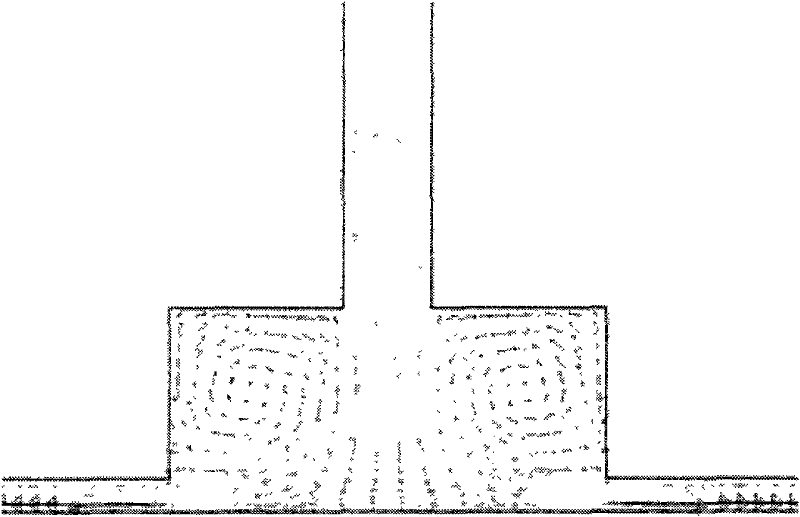

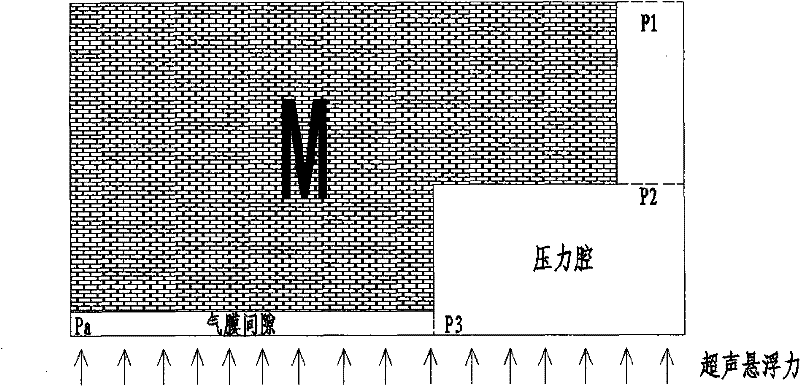

[0031]Its working principle is: the working platform (1), platform base (6) and air bearing (4) are connected together by bolts (5), when the air from the air compressor (17) is filtered, it enters the The air inlet (2), and then the high-pressure gas enters the axial orifice (17) and the pressure chamber (18), and part of the gas enters the flow channel (3), and flows to the radial orifice (7) and the pressure cha...

Embodiment 2

[0033] see Figure 4 , the working platform (1), platform base (6) and air bearing (4) are connected together by bolts (5), when the gas from the air compressor (16) enters the air inlet ( 2), and then the high-pressure gas enters the axial orifice (17) and the axial spherical pressure chamber (19), and part of the gas enters the flow channel (3), and flows to the radial orifice (7) and the radial Spherical pressure chamber (20). The gas from the axial spherical pressure chamber (19) acts on the upper surface of the ultrasonic transducer disc (9), and the gas from the radial spherical pressure chamber (20) acts on the side of the ultrasonic transducer disc (9) superior. This constitutes an air flotation working condition. The ultrasonic transducer disc (9) is fixedly connected with the ultrasonic transducer (11) through the screw (10), and the ultrasonic transducer (11) is fixedly connected with the instrument bracket (14) through the screw (12), and the ultrasonic signal i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com