A digital electronic detonator bridge wire welding assembly

A technology of bridge wire welding components and digital electronic detonators, applied in the field of pyrotechnics manufacturing, can solve the problems of device damage, difficult operation, different axes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

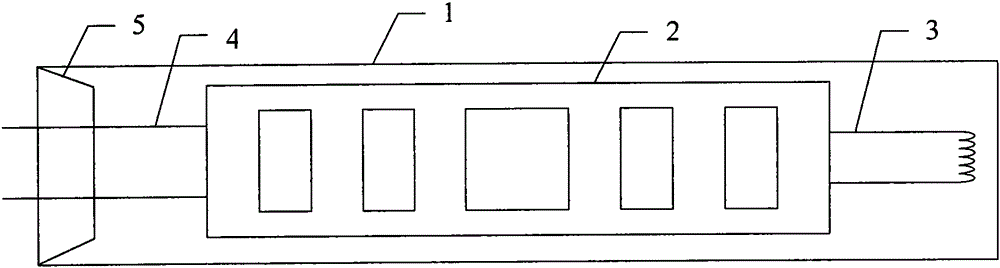

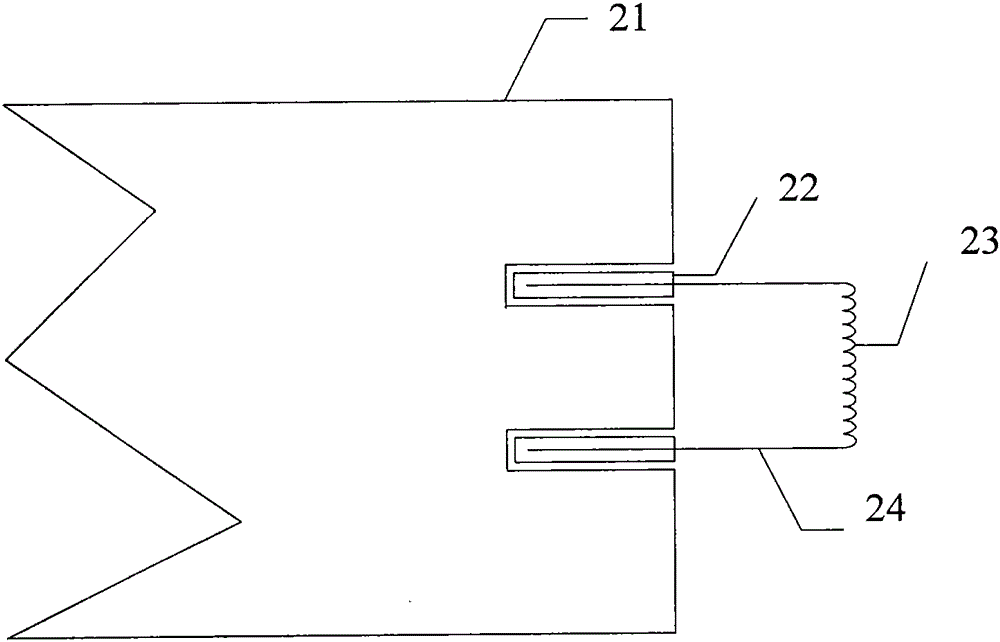

[0025] figure 2 It is a composition schematic diagram of the digital electronic detonator bridge wire welding assembly of the present invention.

[0026] The digital electronic detonator bridge wire welding assembly includes a circuit board 21 , metal parts 22 , bridge wires 23 , and wires 24 .

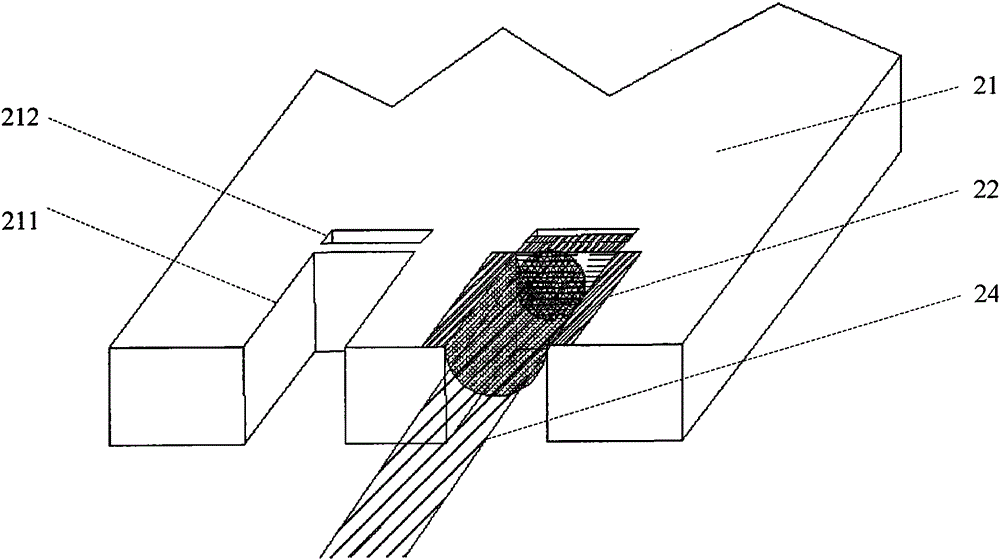

[0027] image 3 It is a schematic diagram of the structure and positional relationship of the circuit board, metal parts, and wires in the present invention.

[0028] The circuit board 21 is designed with a groove 211 and a via hole 212 matching the metal piece 22 .

[0029] Figure 4 It is a schematic diagram of the structure and positional relationship between the circuit board and the metal parts of the present invention.

[0030] The metal piece 22 is composed of three parts, namely a groove part 31 , a supporting part 32 and a bending part 33 .

[0031] The bending portion 33 includes a component one 331 connected to the groove portion 31 and perpendicular to the groove por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com