Spherical element sorting unit

A sorting device and spherical element technology, which is applied to reactor fuel elements, grading, solid separation, etc., can solve the problems of large ball jamming and small ball separation detection gap increase, so as to relieve the jamming and improve the sorting efficiency. Accuracy and the effect of improving sorting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

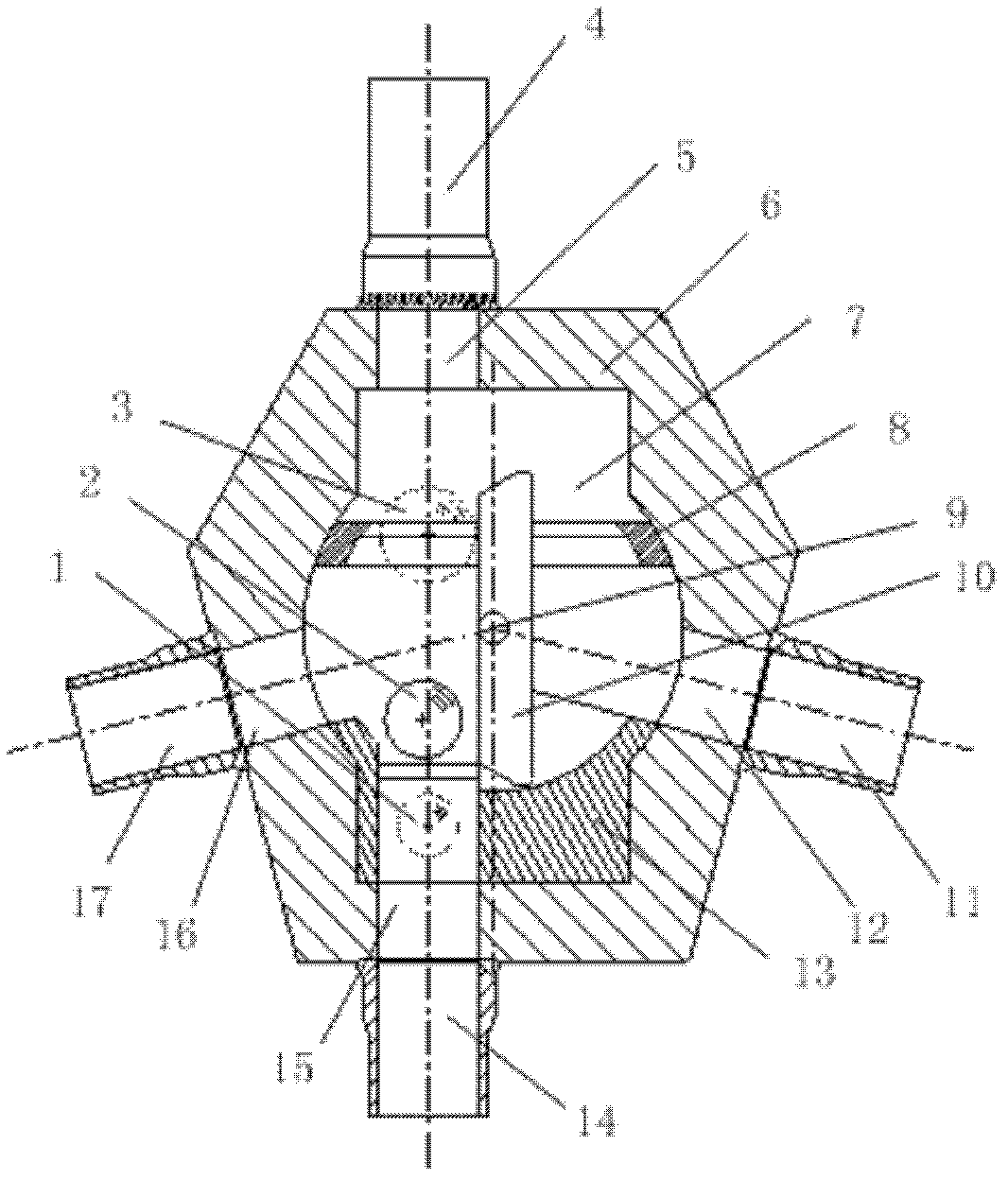

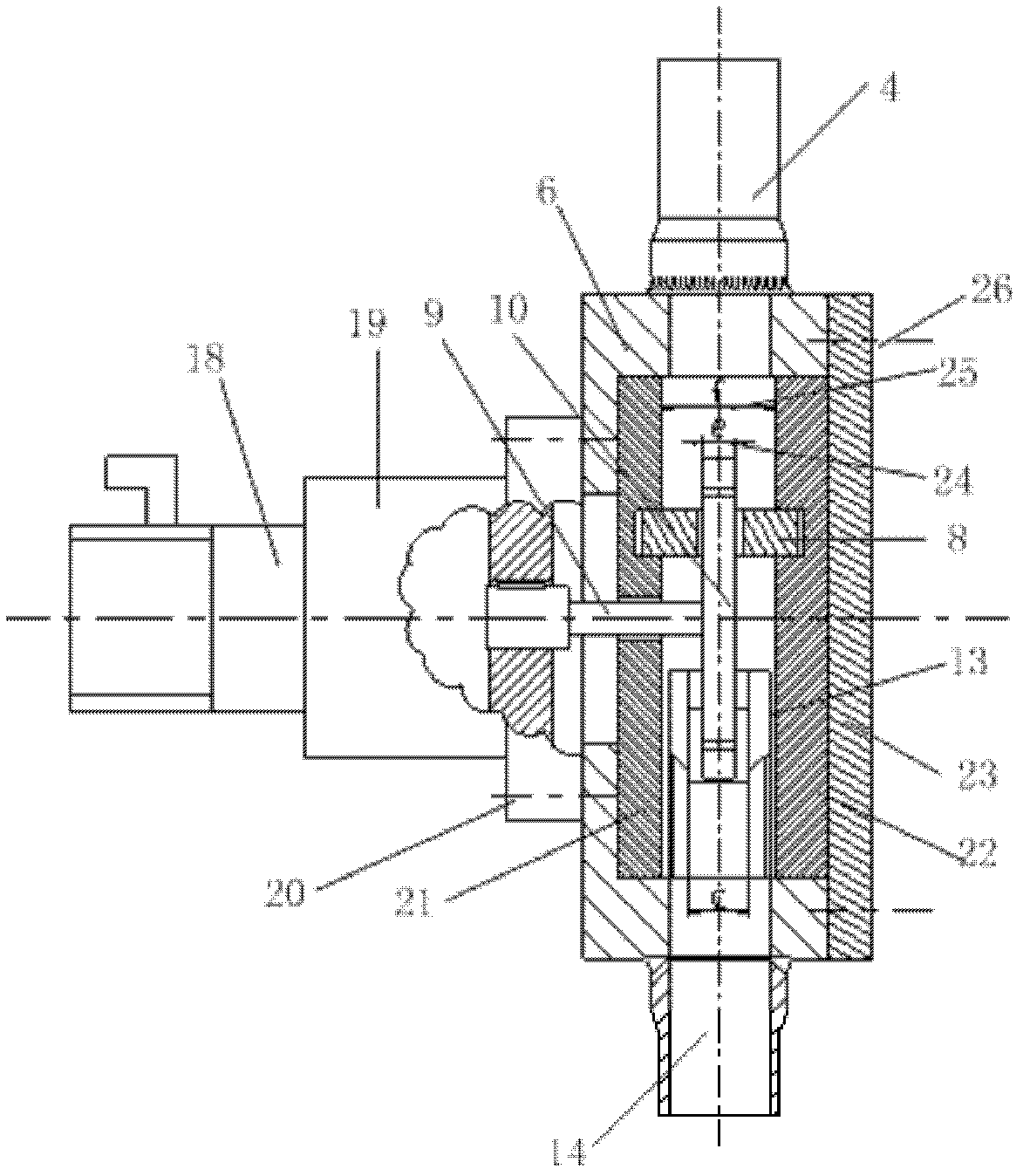

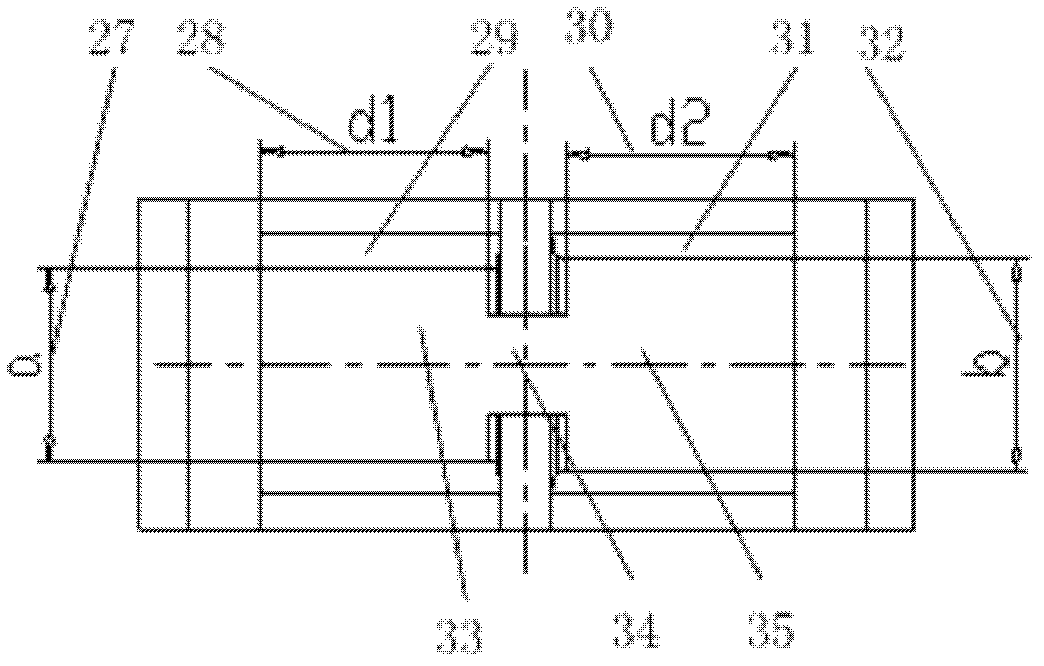

[0030] figure 1 and figure 2 Shows the sectional view and assembly view of the spherical component sorting device according to the first embodiment of the present invention, image 3 and Figure 4 The top views of the two detection orifice plates in the first embodiment of the present invention are respectively shown.

[0031] The sorting device of this embodiment includes two detection orifice plates and three ball outlet pipes, through which the first through hole 27 and the third through hole 36 in the two detection orifice plates cooperate, and the restriction and the dialing of the lining plates on both sides Under the action of the ball, the spherical elements of three sizes, large, medium and small, can be sorted out and discharged through the second ball outlet pipe 11, the third ball outlet pipe 17 and the first ball outlet pipe 14 respectively.

[0032] The spherical element sorting device consists of a driving part 18, a transmission part 19, a box body 6, an en...

Embodiment 2

[0049] Compared with the first embodiment, as Figure 7 The second embodiment shown deletes the third ball outlet pipe 17, and the third ball outlet channel 16 is correspondingly reduced on its casing 6, therefore, it can be used for sorting spherical elements of two sizes, and two sizes The components are respectively discharged through the first outlet pipe 11 and the second outlet pipe 14, and its working principle is the same as that of the first embodiment.

Embodiment 3

[0051] On the basis of Embodiment 1, the structure of this embodiment has the following changes: (1), the number of ball outlet pipes is reduced to one, and the number of ball outlet channels on the box body 6 is correspondingly reduced to one; (2), the first detection The first channel 33 of the orifice plate is no longer communicated with the second passage 35, but is cut off by 34. Correspondingly, the movement mode of the driving rod 10 is changed into a swing type by a rotary type; The axis of the tube 14 is no longer eccentric, but is located on the symmetric plane of the box body 6, so the driving lever 10 is an eccentric structural plate, and the clearance between the through hole 7 of the lower box body 6 can be used to ensure that the spherical element can be introduced into the hole of the detection orifice plate 8. The first channel guides the inclined surface 29 places.

[0052] Since there is only one ball outlet pipe, the third embodiment cannot independently so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com