Electrical machine for motor vehicle, motor vehicle with electrical machine and method for designing motor vehicle

A car, engine compartment technology, applied in the field of motors for cars, cars with motors, and for designing cars, which can solve problems such as limited space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

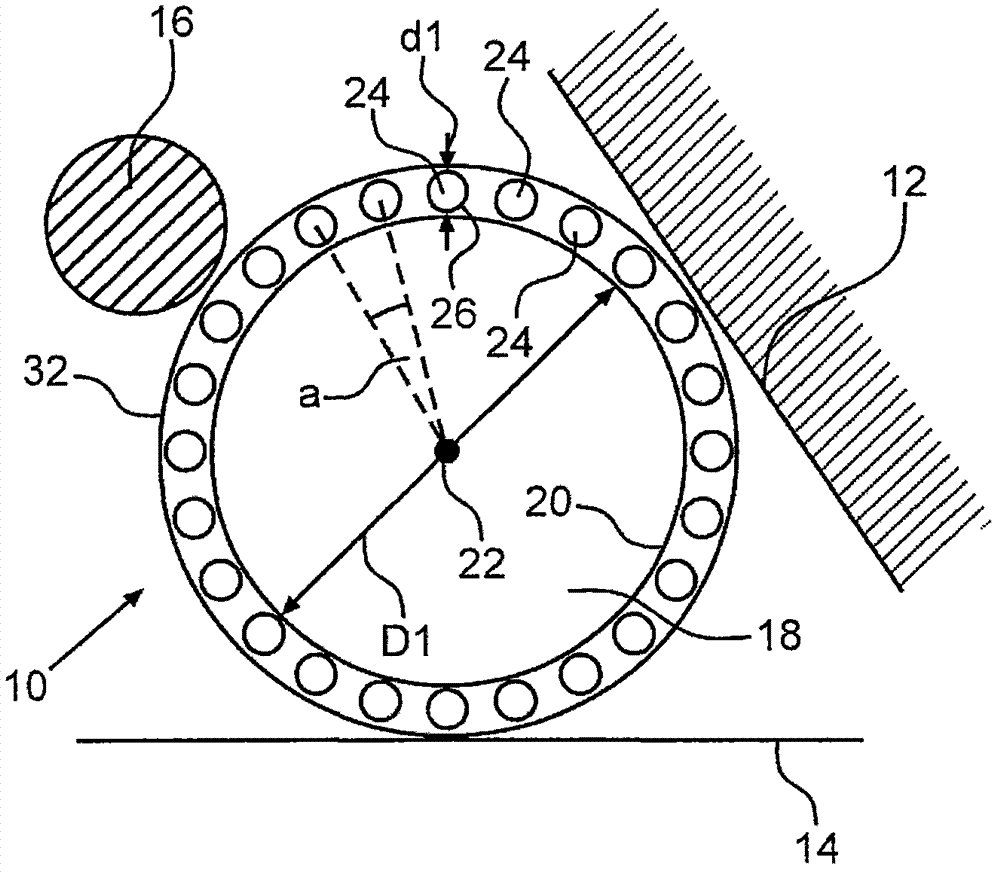

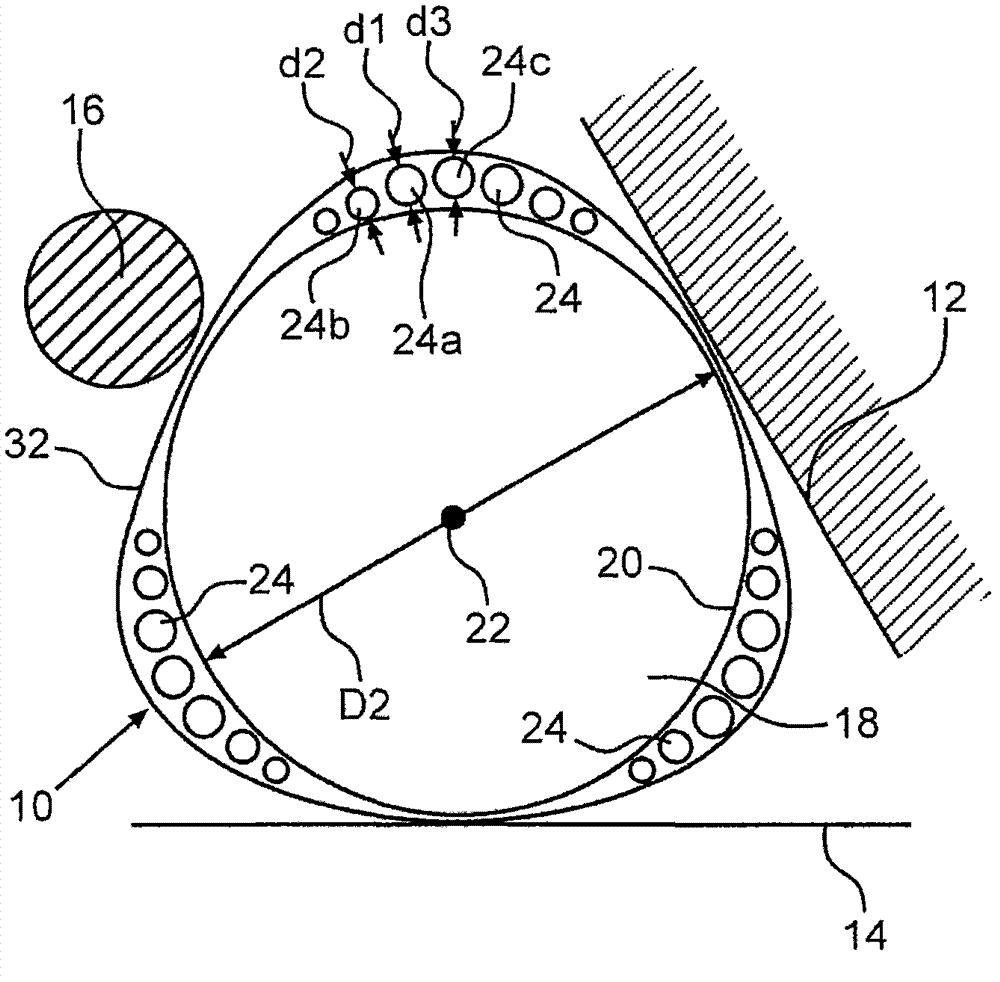

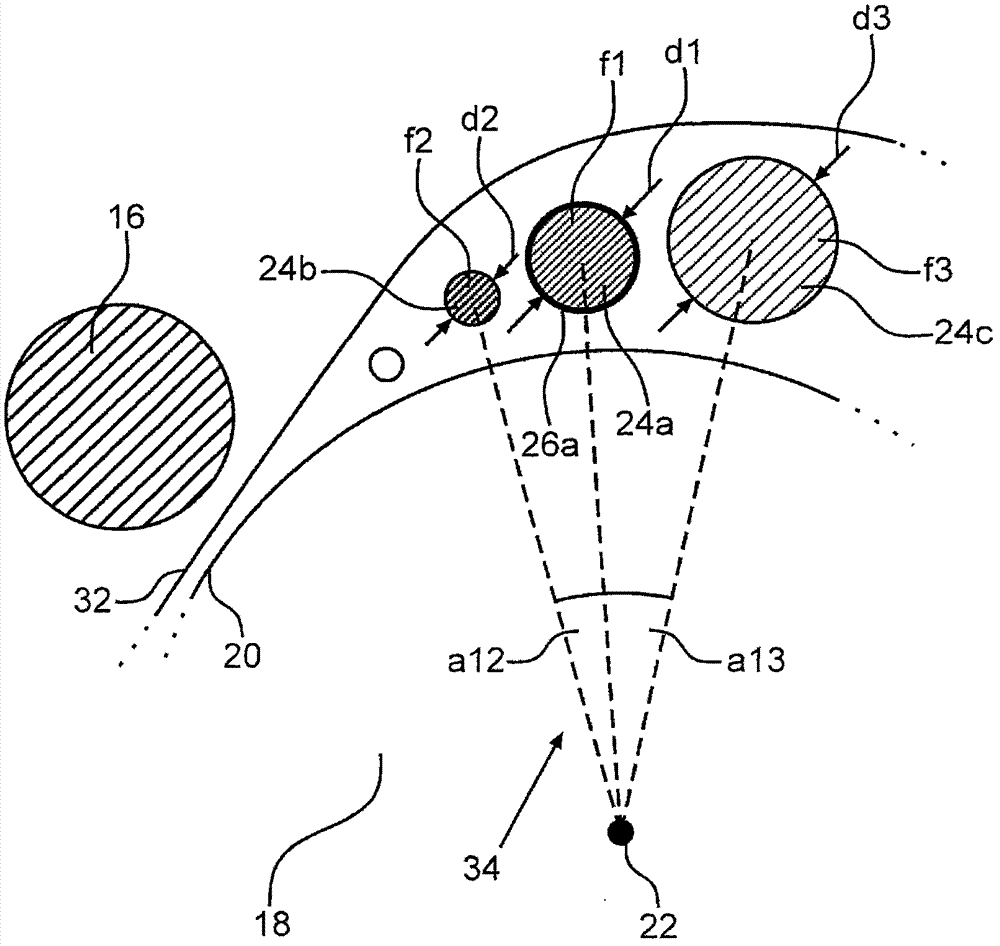

[0029] figure 1 A schematic sectional view of an engine compartment of a motor vehicle is shown, in which an electric machine 10 known from the prior art is arranged. The electric machine 10 includes a core region 18 in which a rotor is mounted rotatably about a rotor axis of rotation 22 . The core region 18 has a circular cross-section with a diameter D1 and its perimeter is delimited by a circumferential profile 20 . In addition to the rotor, the core region 18 can include further components, in particular a stator, coil windings and a stator carrier. In this case, the coil winding can extend, for example, over the entire circumferential area of the core region 18 inside the circumferential contour 20 . The coil windings can also be arranged only in partial sections of the circumferential contour 20 . This may be the case, for example, if the electric machine 10 is a three-phase electric machine. Furthermore, the electric machine 10 comprises cooling medium channels 24...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap