Cutter edge protector for combine harvester

A technology for combine harvesters and blade guards, applied to harvesters, agricultural machinery and implements, applications, etc., can solve the problems of fragile blade guards, long pods, and low strength, and achieve reasonable and practical structural design and ingenious ideas Novelty, long-lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

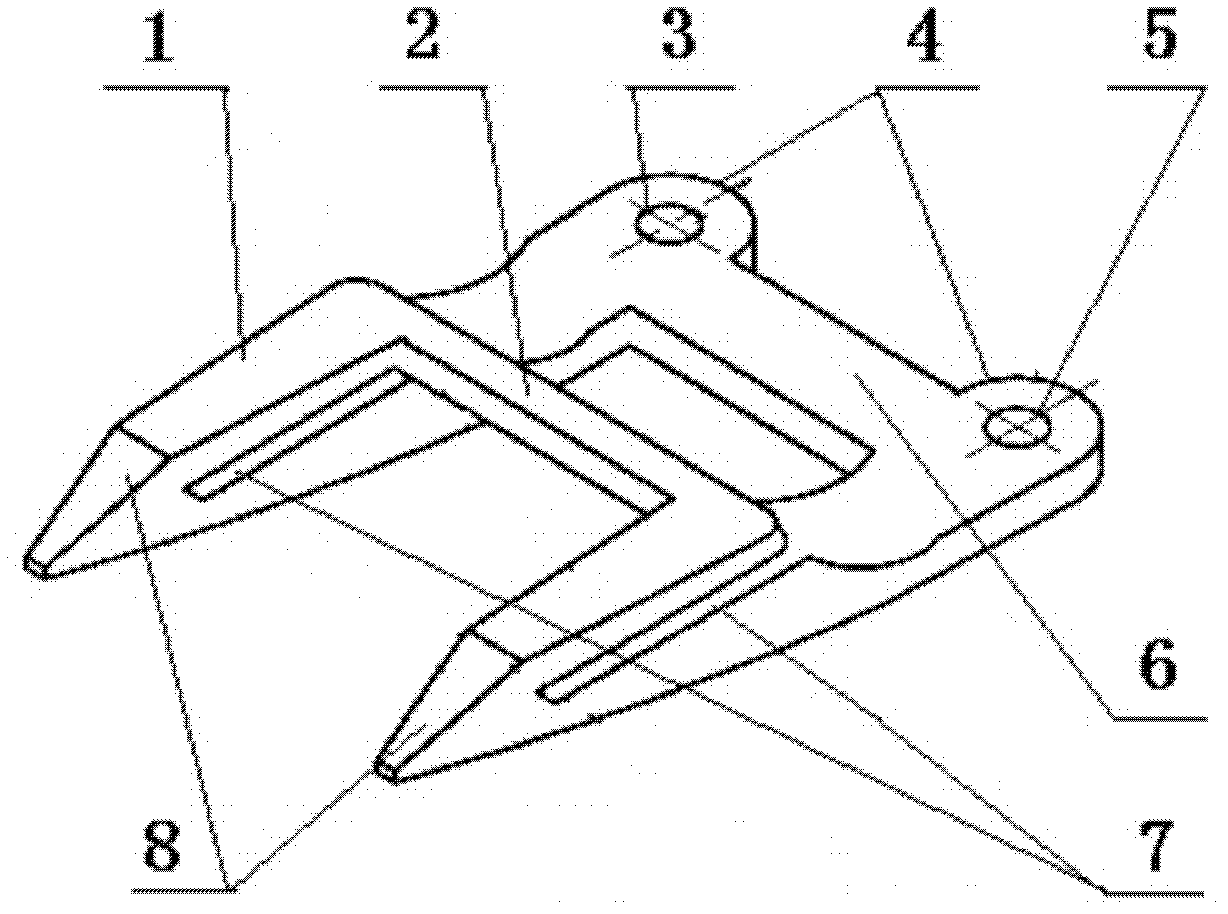

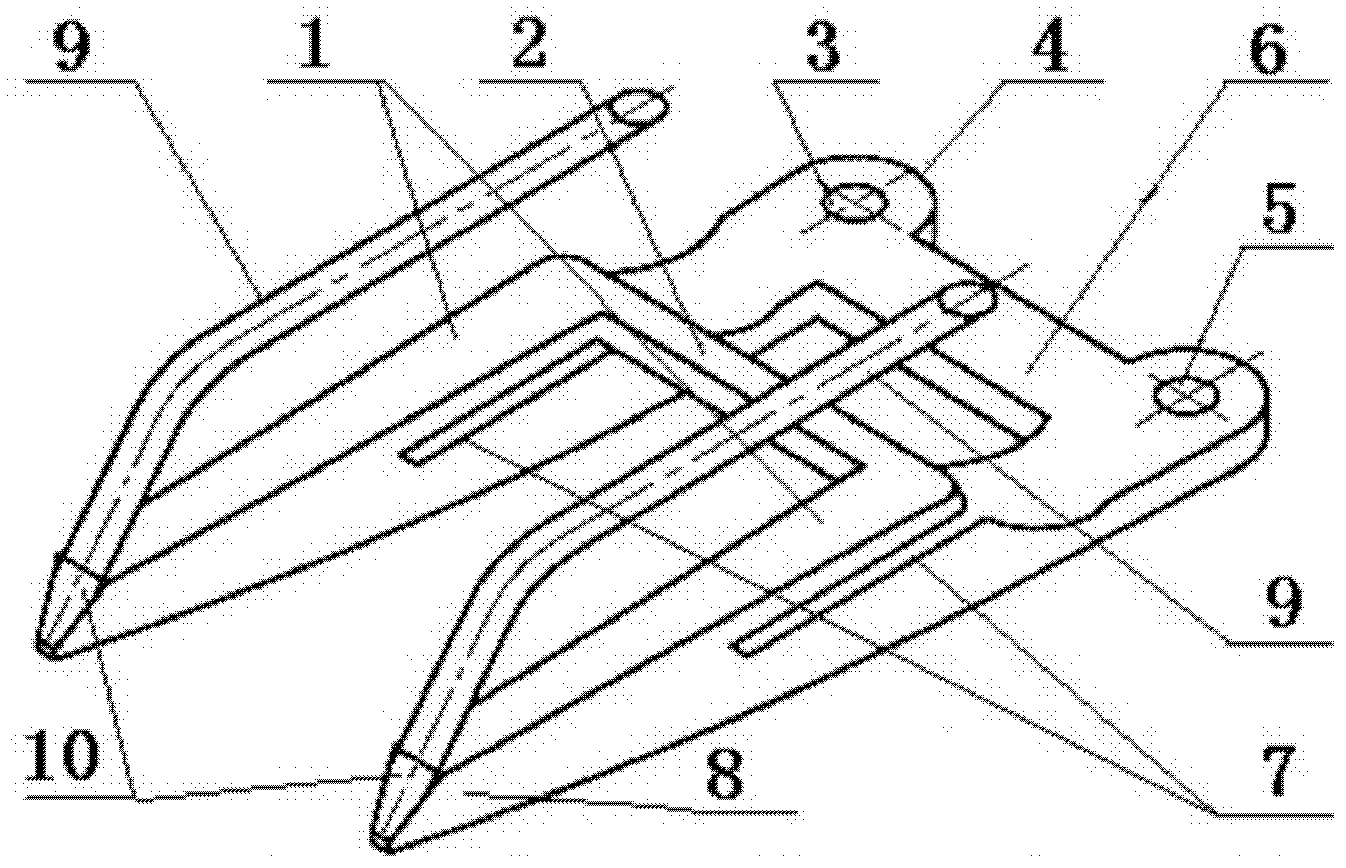

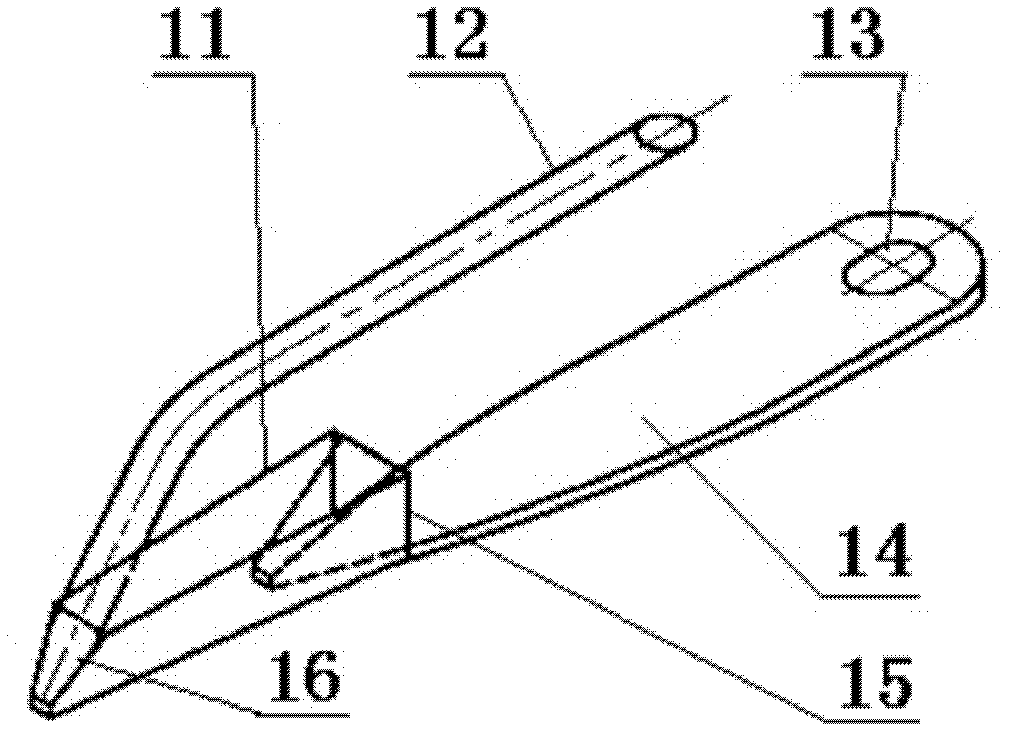

[0024] Specific embodiments of the present invention, such as Figure 1-7 Shown, a kind of combine harvester cutter blade protector, comprises blade protector main body 6, two independent blade protector upper covers and blade protector slot 7 on both sides of the front part of blade protector main body 6, the blade protector main body 6 The front cone head 8 and the blade guard mounting ear 4 of the blade guard provided at the front and rear ends, and the left mounting hole 3 and the right mounting hole 5 on the blade guard mounting ear 4, wherein the blade guard main body 6 Similar to the inverted U shape, the two sides of the inverted U shape of the main body of the blade guard are two upper covers of the blade guard, which are characterized by:

[0025] A, between the open ends of the two blade guard upper covers on both sides of the blade guard main body 6, connecting ribs 2 are set, and the two blade guard upper covers are connected into one blade guard upper cover 1, su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com