Method for preparing pumpkin dietary fiber

A technology of dietary fiber and dietary fiber powder, applied in food preparation, food science, application and other directions, can solve the problems of food resource waste, decay and other problems, achieve high SDF content, improve functional properties, and increase the effect of SDF content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

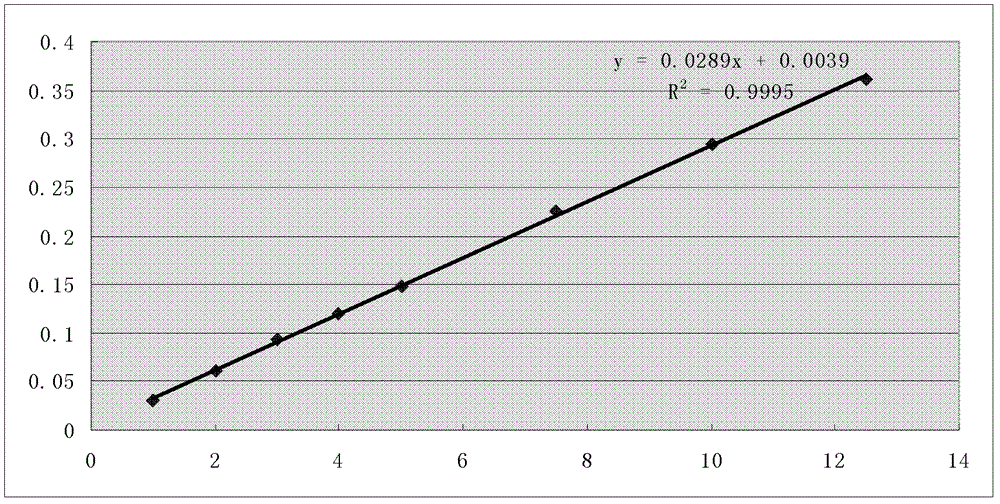

Image

Examples

Embodiment 1

[0032] 1Materials and reagents

[0033] Pumpkin (provided by Zhejiang Fulaisen Green Industry Group Company). Before use, peel and remove the flesh, cut into shreds and dry naturally, crush it mechanically, and screen the sample with 100 meshes for use.

[0034] Total dietary fiber determination kit (TDF 100A-1KT, purchased from Sigma-Aldrich), sodium nitrite, petroleum ether, sodium hydroxide, sodium carbonate, sulfuric acid, hydrochloric acid, phenolphthalein, citric acid, etc. are all analytically pure.

[0035] 2 Experimental equipment

[0036] Crusher, AL04 electronic balance, DELTA-320 pH meter, HH-2 water bath, ZHENGFCHEN double-layer constant temperature shaker, DHG-9240A blast drying oven, DL-5M centrifuge (with replacement rotor), 85-Z magnetic stirrer, T6 new century spectrophotometer, muffle furnace, digestion furnace, dietary fiber determination system (including CSF6, MULTISTIRRER6 and GDE enzyme digestion components, purchased from Italy VELP SCIENTIFICA Co.).

[0037] ...

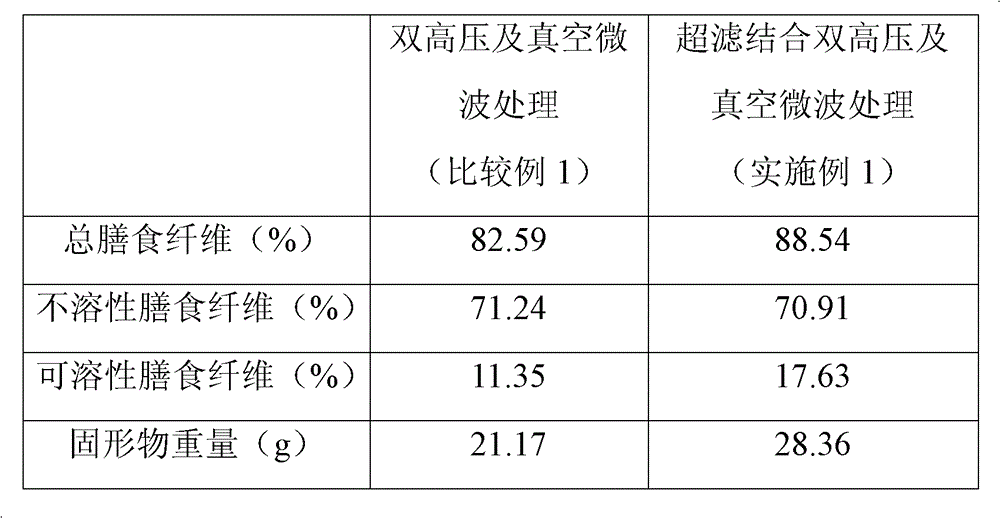

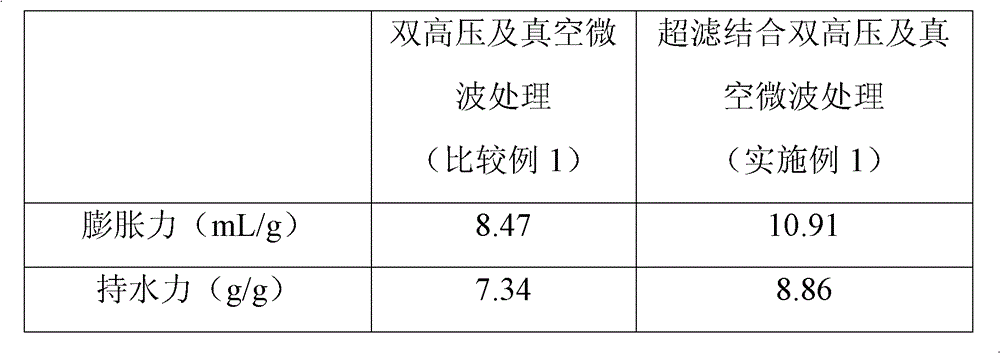

Embodiment 2

[0073] Take 40g of pumpkin powder that has passed the 100-mesh sieve prepared by the method in Example 1, mix with 800g of water, extract at 40°C for 90min, centrifuge at 3000r / min for 30min, and obtain 230mL of supernatant for one extraction and after one extraction The filter residue after the primary extraction is extracted once again under the same conditions to obtain 210 mL of the secondary supernatant and the filter residue after the secondary extraction. The two supernatants are combined, and the supernatant 440mL is 10kD The polyethersulfone membrane was subjected to membrane filtration, and the concentrated solution that was not filtered through the membrane was collected to obtain 85 mL of concentrated solution for use. Other operations and conditions are the same as in Example 1, to obtain 25.67 g of pumpkin dietary fiber, total dietary fiber content of 84.26%, soluble dietary fiber content of 14.16%, and expansion force of 8.87 mL / g.

Embodiment 3

[0075] Take 40g of pumpkin powder that has passed the 100 mesh sieve prepared by the method in Example 1, mix with 2400g of water, extract at 40°C for 180min, centrifuge at 3000r / min for 30min, and obtain 840mL of supernatant for one extraction and after one extraction The filter residue after the primary extraction is extracted once again under the same conditions to obtain 780 mL of the secondary extraction supernatant and the filter residue after the secondary extraction. The two supernatants are combined to 1620 mL, and the supernatant is used Perform membrane filtration with a 10kD polyethersulfone membrane, and collect the concentrated solution that has not been filtered through the membrane to obtain 180 mL of concentrated solution for use. Other operations and conditions are the same as in Example 1, to obtain 27.87 g of pumpkin dietary fiber, 88.19% of total dietary fiber content, 16.12% of soluble dietary fiber content, and swelling power of 9.78 mL / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com