Vertebral arch pedicle screw system capable of being embedded with minimal invasion

A pedicle screw and placement technology, applied in the direction of internal fixator, internal bone synthesis, fixer, etc., can solve the problem of high difficulty of fixation rod, achieve the effect of saving operation time, convenient loading and unloading, and improving operation quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

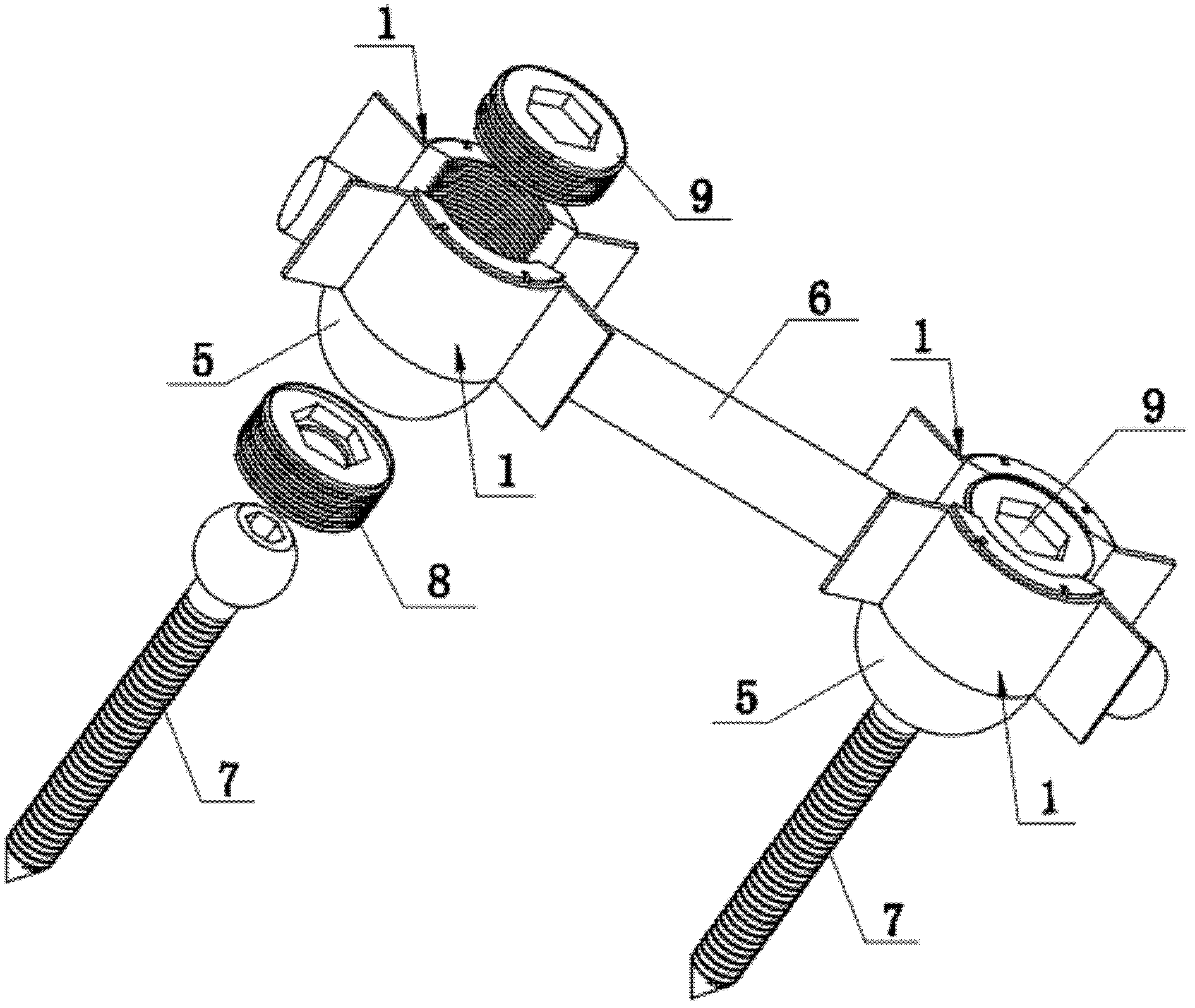

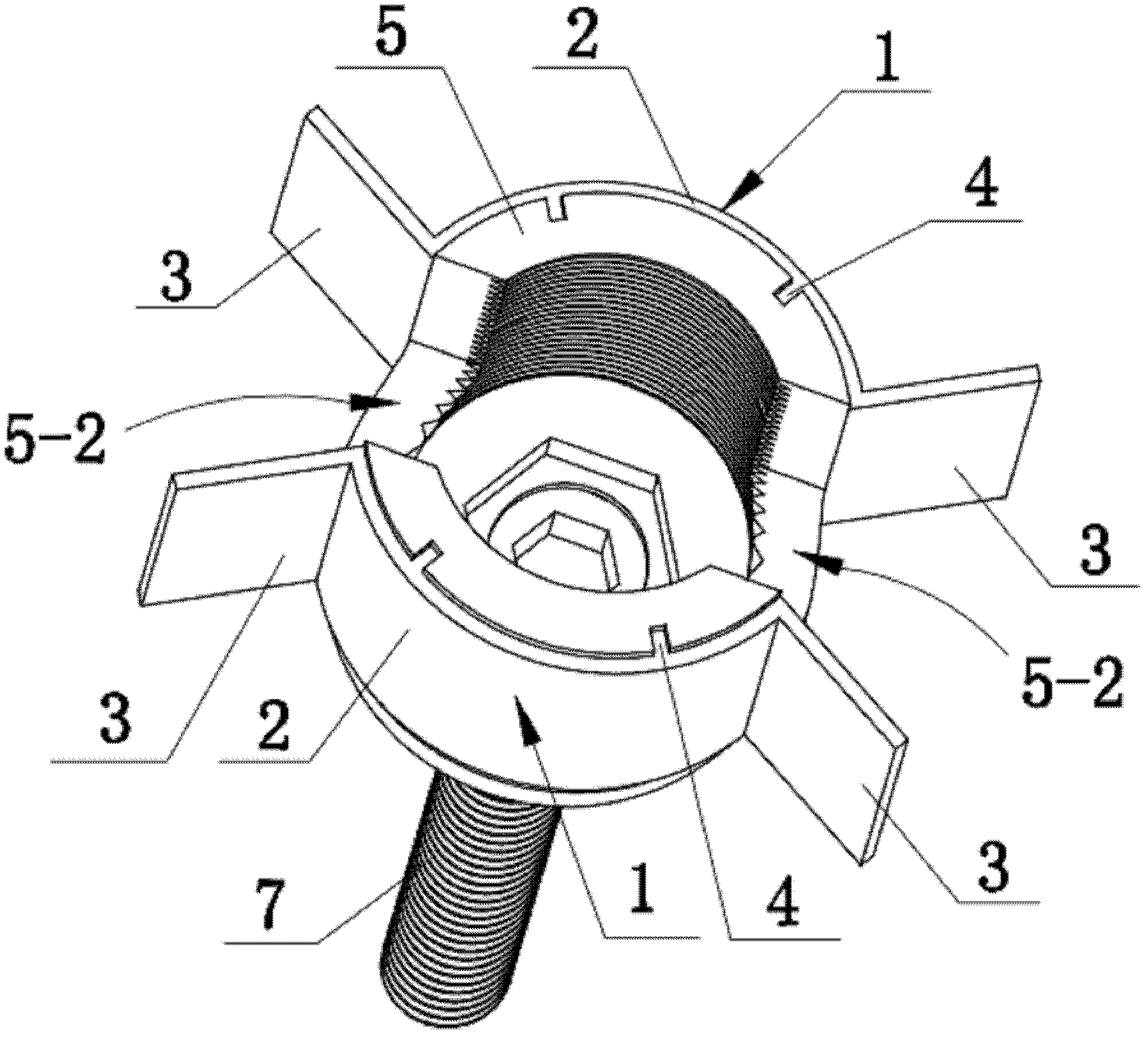

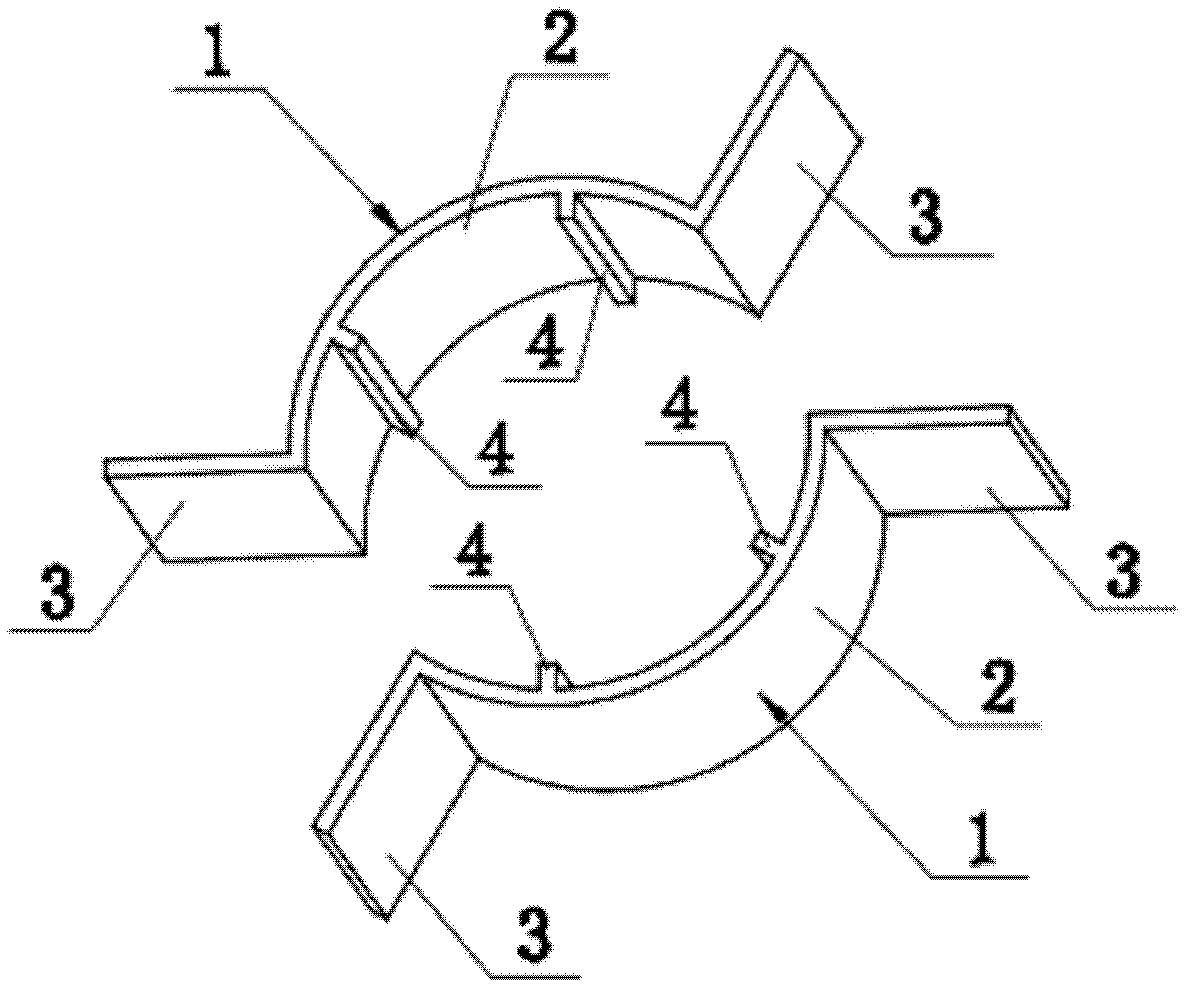

[0021] see figure 1 , the minimally invasive implantable rod pedicle screw system of this embodiment is a universal screw rod pedicle screw system, the universal pedicle screw system is composed of two screw assemblies and a fixation rod 6, Wherein, each screw assembly is composed of a nail seat 5, a pedicle screw 7, a ball head pressure block 8 and a screw plug 9. The cross section of the nail seat 5 is circular, and the center is provided with an axial The through hole of the pedicle screw 7, the lower part of the through hole is a hemispherical socket, and the upper part is a cylinder with an internal thread on the inner wall. The nail cap of the pedicle screw 7 is spherical, and it is matched with the nail when installed. In the hemispherical socket of the seat 5, the lower end of the ball head 8 is provided with a hemispherical socket that matches the spherical cap of the pedicle screw 7, and the ball head 8 is screwed to the screw seat 5. In the hole, the hemispherical ...

Embodiment 2

[0025] see Figure 7 and Figure 8 , The difference between this embodiment and Embodiment 1 is that the number of screw assemblies in this example is three, and the guide wings 3 at both ends of the arc plate 2 on the half guide 1 are arcs folded backwards Shape, that is, the orientation of the arc guide wing 3 arch is opposite to that of the arc plate 2 arch, so that the opening of the bell mouth formed by the two guide wings 3 is larger, which is more conducive to guiding the insertion of the fixing rod 6. In addition, the protrusions 4 provided on the circular arc plate 2 are changed from the continuous strip shape of the embodiment 1 to two discontinuous distribution bosses, and these two bosses are respectively arranged on the arc plate 2 the upper and lower edges of the .

[0026] Embodiments other than the above in this embodiment are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com