After-treatment technology of Beckmann gas-phase rearrangement S-1 full-silica molecular sieve based catalyst

An all-silicon molecular sieve, S-1 technology, used in molecular sieve catalysts, catalyst activation/preparation, physical/chemical process catalysts, etc. Problems such as small selection range, to achieve the effect of reducing energy consumption and saving equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Dilute hydrochloric acid with deionized water until the H+ concentration is 0.02 mol / l, add hydrofluoric acid with deionized water and dilute to 0.02% by mass fraction, and then mix the two solutions at a volume ratio of 1:3 for later use.

[0026] Weigh 40g of S-1 all-silicon molecular sieve catalyst and put it into a reactor made of polytetrafluoroethylene or polypropylene, measure 200ml of the mixed solution of strong acid and hydrofluoric acid and pour it into the reactor, start stirring, and the speed is 50r / min, react at room temperature for 2h, stop stirring, and wash with deionized water until neutral. Repeat this process 3 times. After the reaction is completed, the S-1 all-silicon molecular sieve is dried and calcined at 500°C for 3 hours to obtain the S-1 all-silicon molecular sieve catalyst product.

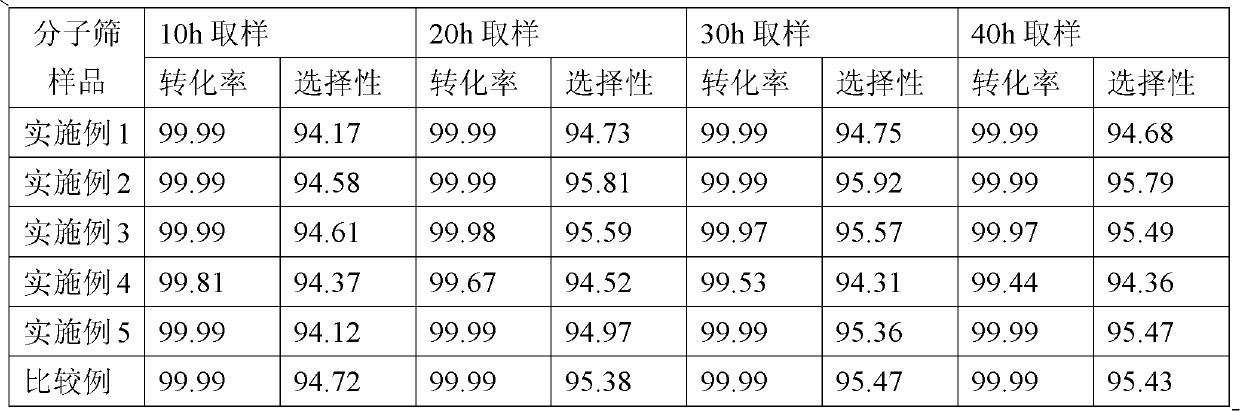

[0027] Table 1 shows the catalyst evaluation results for the gas-phase Beckmann rearrangement of S-1 all-silicon molecular sieve for the synthesis of caprolac...

Embodiment 2

[0029] Dilute sulfuric acid with deionized water to H + The concentration is 0.03 mol / l, and the hydrofluoric acid is added to deionized water to dilute to a mass fraction of 0.06%, and then the two solutions are mixed at a volume ratio of 1:2 for later use.

[0030] Weigh 60g of S-1 all-silicon molecular sieve catalyst and put it into a reactor made of polytetrafluoroethylene or polypropylene, measure 400ml of the mixed solution of strong acid and hydrofluoric acid and pour it into the reactor, start stirring, and the speed is 80r / min, react at room temperature for 3h, stop stirring, and wash with deionized water until neutral. Then, this reaction was repeated 3 times under the same conditions. After the reaction is completed, the S-1 all-silicon molecular sieve is dried and calcined at 550° C. for 4 hours to obtain the S-1 all-silicon molecular sieve catalyst product.

[0031] Table 1 shows the catalyst evaluation results for the gas-phase Beckmann rearrangement of S-1 all...

Embodiment 3

[0033] Dilute hydrochloric acid with deionized water to H + The concentration is 0.05 mol / l, adding deionized water to dilute hydrofluoric acid to a mass fraction of 0.1%, and then mixing the two solutions at a volume ratio of 1:1 for later use.

[0034]Weigh 80g of S-1 all-silicon molecular sieve catalyst and put it into a reactor made of polytetrafluoroethylene or polypropylene, measure 800ml of the mixed solution of strong acid and hydrofluoric acid and pour it into the reactor, start stirring, and the speed is 100r / min, react at room temperature for 4h, stop stirring, and wash with deionized water until neutral. Repeat this process 3 times. After the reaction is completed, the S-1 all-silicon molecular sieve is dried and calcined at 600°C for 5 hours to obtain the S-1 all-silicon molecular sieve catalyst product.

[0035] Table 1 shows the catalyst evaluation results for the gas-phase Beckmann rearrangement of S-1 all-silicon molecular sieve for the synthesis of caprolac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com