Reinforcing polar line

A technology of pole line and reinforced teeth, applied in the direction of electrode structure, electrostatic separation, etc., can solve problems such as corona vacuum, achieve the effect of good dust removal, improve dust collection efficiency, and increase dust collection area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

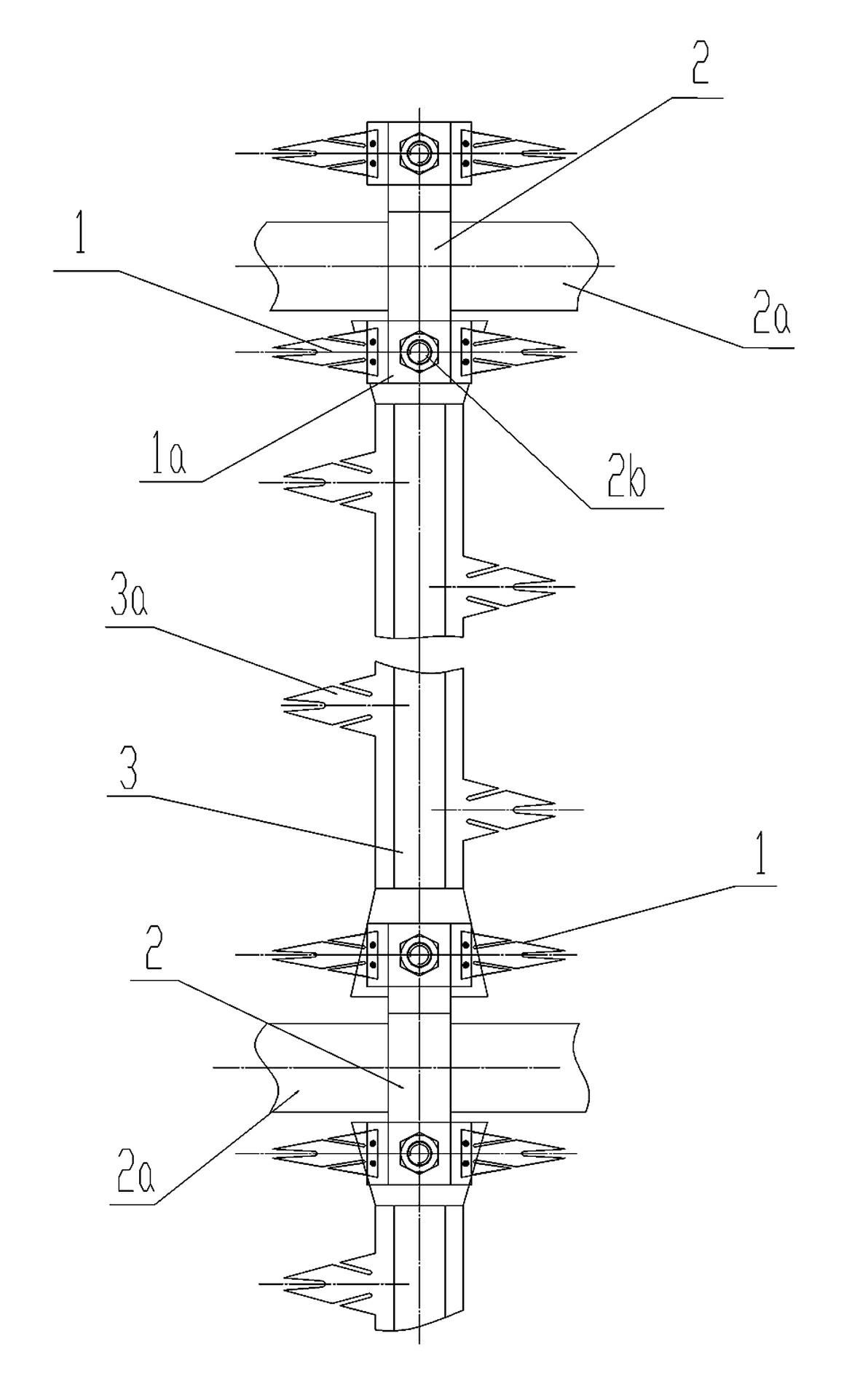

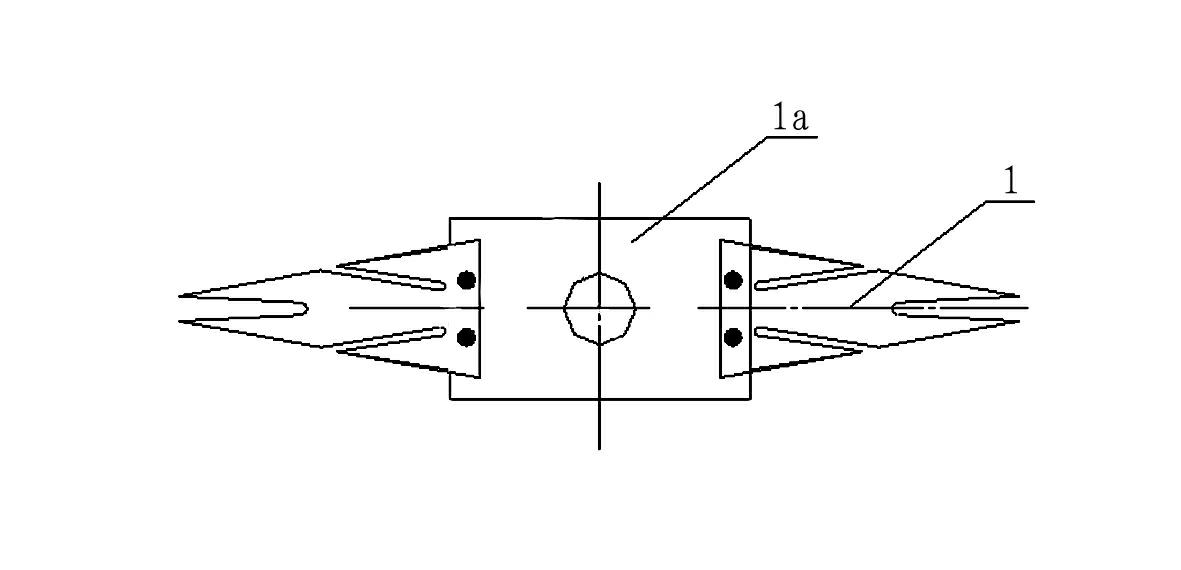

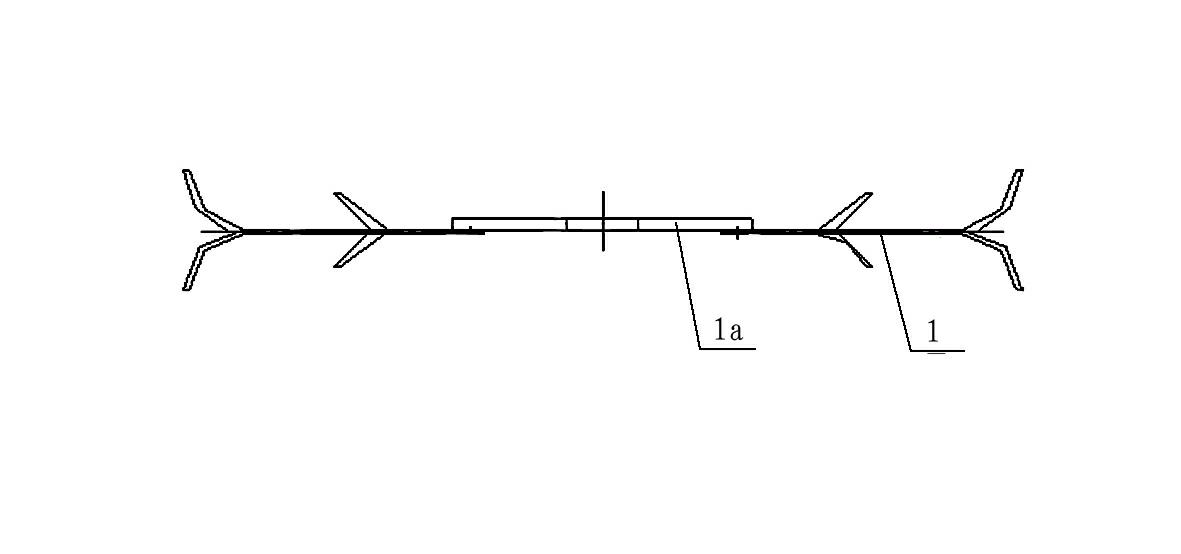

[0013] Such as figure 1 , figure 2 and image 3 As shown, a reinforced polar wire provided by the present invention includes a polar wire 3 and thorn-shaped polar wire teeth 3a arranged staggeredly on the polar wire 3. A connecting plate 1a is respectively arranged at both ends of the polar wire 3, and the two sides of the connecting plate 1a are respectively There is a burr-shaped polar line reinforcement tooth 1 welded, and the center of the connecting plate 1a is provided with a connecting hole that matches the tube clamp 2, and the connecting plate 1a, the polar line 3 and the tube clamp 2 are connected to the upper and lower cathode frames by bolts 2b 2a on.

[0014] Through the pole line strengthening teeth of the present invention, there are also thorn teeth at the pipe clamp, which can fill the corona vacuum at the pipe clamp, so that the corona of the entire electric field is relatively uniform, so that the equipment can be increased without changing the equipment....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com