Coordinate conjugate gradient computing method for roller rows of continuous bending and straightening segments of continuous casting machine for slabs

A slab continuous casting machine and coordinate calculation technology, applied in the field of slab continuous casting machine roll row design, can solve problems such as less mastery, and achieve the effects of accurate approximation accuracy and fast calculation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

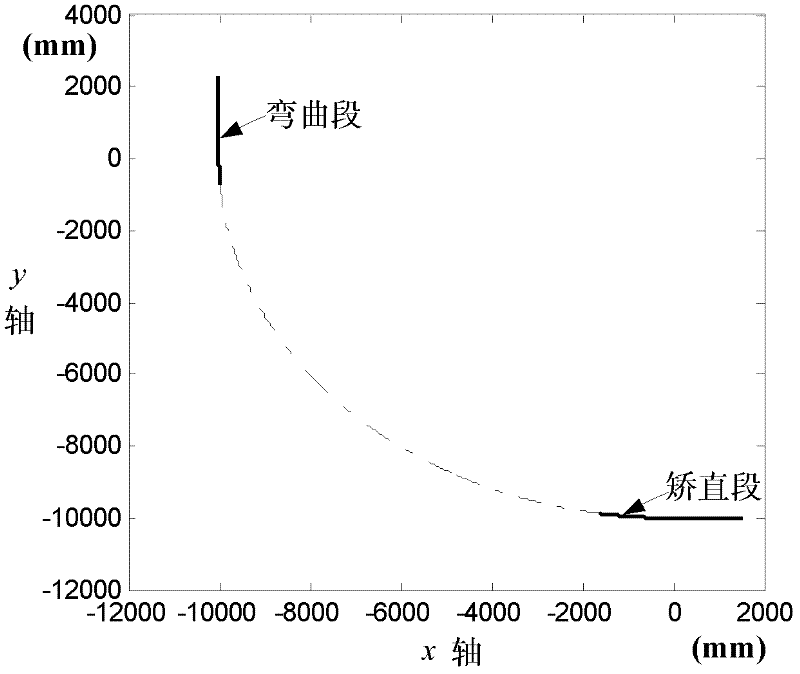

[0080] The parameters of the bending section and the straightening section of a slab continuous casting machine in a steel plant are the slab thickness D = 250mm, the slab width B = 2300mm, and the basic arc radius R 0 =10000mm, the length of the bending zone L b =1400mm, the length of straightening zone L s = 3150mm.

[0081] Then the continuous casting machine bending zone coefficient K b = 1.00747, bending zone angle α b =4.03399°, the total arc length S of the bending zone b =1400.7mm; Straightening zone coefficient K s =1.04056, straightening zone angle α s =9.30735°, total arc length S in straightening zone s = 3158.43 mm.

[0082] The coordinates of the starting point of the bending zone are (-10008.14, 696.52), the coordinates of the end point of the bending zone are (-9975.22, -703.48), the coordinates of the starting point of the straightening zone are (1532.7, -10040.43), and the coordinates of the end point of the straightening zone are (-1617.30, -9868.35 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com