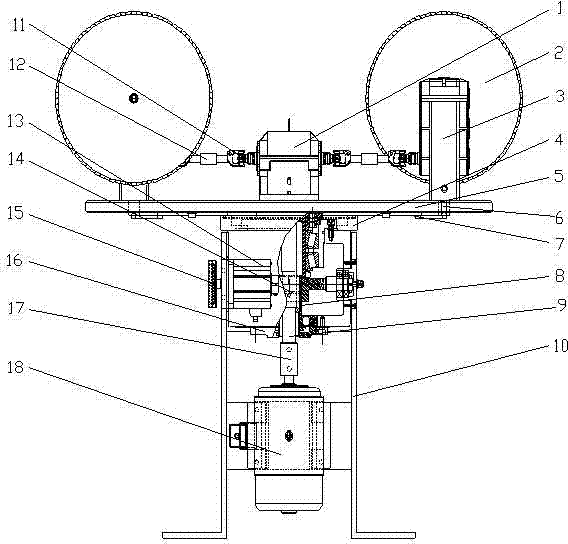

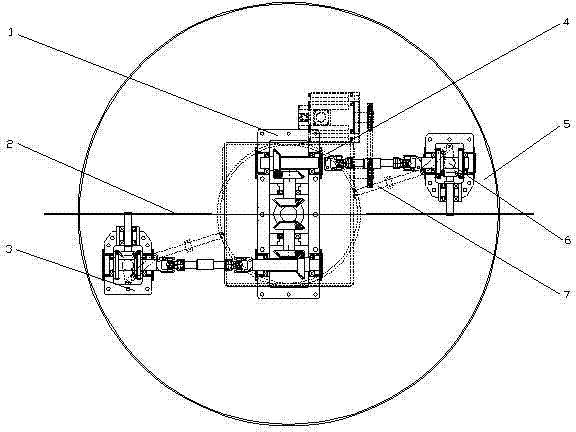

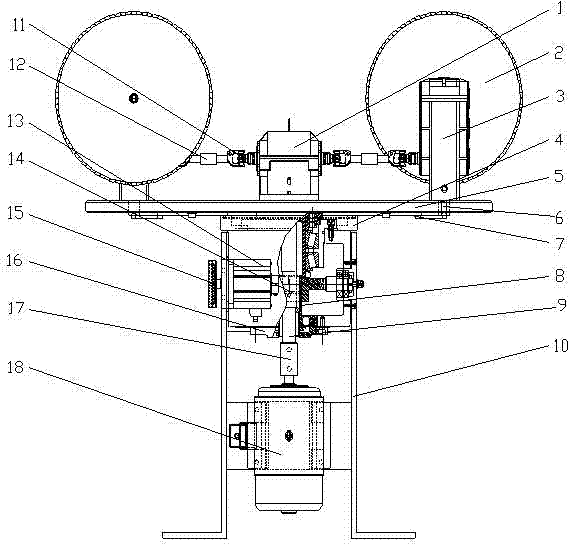

Rotary sawing machine with double saw blades

A sawing machine, rotary technology, applied in the direction of metal sawing equipment, sawing machine, metal processing equipment, etc., to achieve the effect of improving cutting efficiency and precision and reducing accumulated errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] A rotary sawing machine with double saw blades comprises a saw blade 2, a machine base 10, a rotary pan 5, a saw blade transmission mechanism, a sawing machine guide mechanism, and a rotary pan transmission mechanism. The support 10 is fixed on the ground, and the saw blade transmission mechanism includes. AC motor 18, main transmission shaft 9, sawing mechanism gear box 3 and transmission gear box 1. The AC motor 18 is fixed below the machine base 10, the main shaft of the AC motor 10 is connected with the main transmission shaft 9 through the coupling 17, the upper end of the main transmission shaft 9 is arranged in the transmission gearbox 1, and the transmission gearbox 1 is fixed on the rotary market 5 Above, the output shaft of the transmission gearbox 1 is connected to one end of the universal joint coupling 11, and the other end of the universal joint coupling 11 is connected to a telescopic shaft 12, and the telescopic shaft 12 is connected to the The gear box...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap