Pneumatic clamp pressing mechanism for automotive body welding

A technology for pneumatic fixtures and automobile bodies, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., to save costs, enhance process feasibility and convenience of operation, and increase welding space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

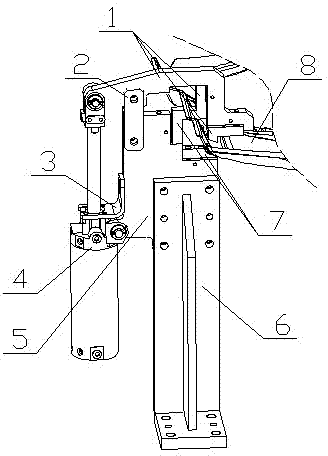

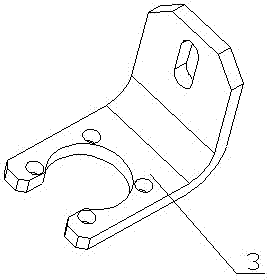

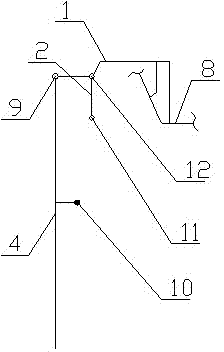

[0022] see Figure 1-4 , a pneumatic clamping mechanism for automobile body welding, which includes a pressing unit 1, a hinged plate 2, a cylinder rotation limiter 3, a cylinder 4, a connecting plate 5, a support 6, and a positioning block 7, wherein the hinged plate and The connection plate is hinged, the positioning block is fixed on the connection plate, and the connection plate is fixed on the support; the cylinder is connected to the compression unit. When working, the workpiece is clamped between the positioning block and the compression unit. A cylinder rotation limiter 3 is arranged between them, and the cylinder rotation limiter is fixedly connected to the connecting plate; the pressing unit is hinged to the hinge plate. The cylinder rotation limiter is L-shaped, one end of which is fixed on the upper end of the cylinder block, and the other e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com