Bracket of machine tool

A technology of machine tools and outriggers, which is applied in the direction of metal processing machinery parts, large fixed members, metal processing equipment, etc., can solve the problems such as difficult to decompose the driving force, achieve good support effect, reduce the risk of machine tool rollover, and quickly fold and store Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

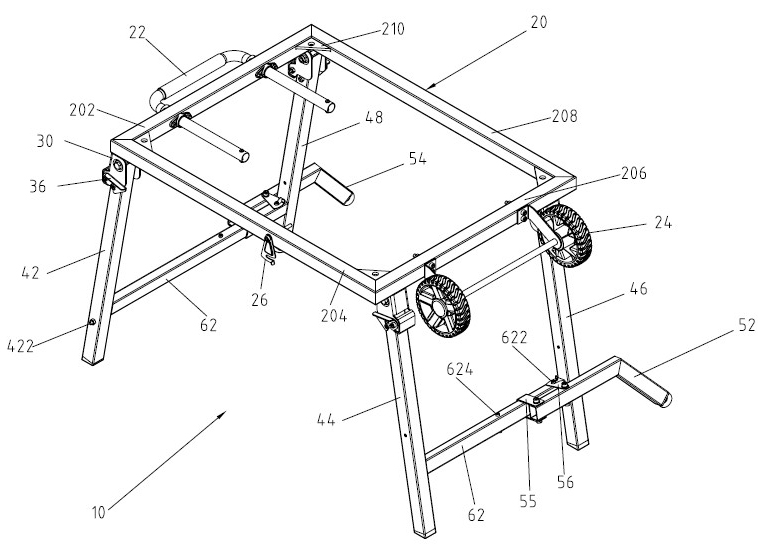

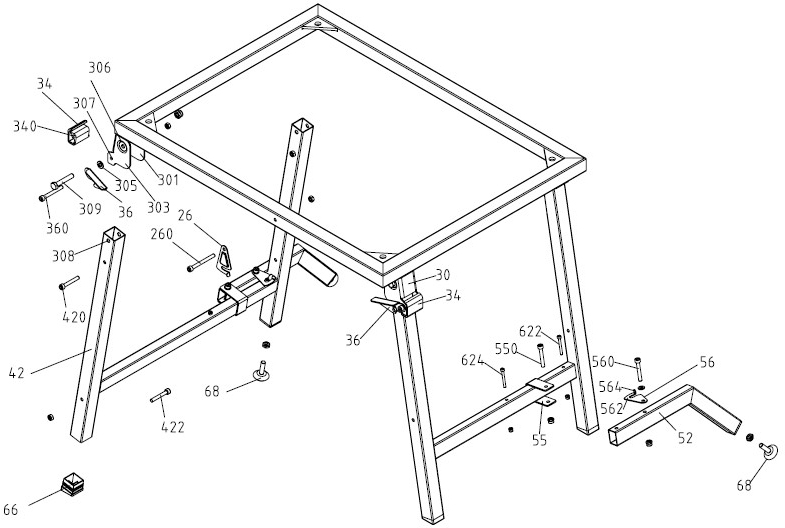

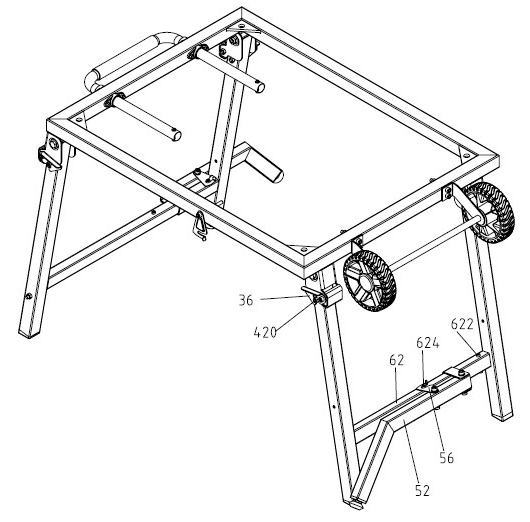

[0072] see figure 1 Shown is a machine tool support 10 of a preferred embodiment of the present invention, has a support platform 20 and four legs 42, 44, 46, 48, each leg is pivoted by a pivot bolt 309 and a connecting plate 30 Connected on the support platform 20, reinforcing beams 62 are respectively arranged between the legs 42, 48 and between the legs 44, 46, and the auxiliary legs 52, 54 are pivotally connected to the reinforcing beams 62 through the sleeve plate 55, and the auxiliary legs The legs are used to effectively expand the contact area.

[0073] The support platform 20 is a frame body with a left side frame 202, a front side frame 204, a right side frame 206 and a rear side frame 208, wherein the left side frame 202 is fixed with a U-shaped handle 22 for users to hold, and the right side frame A pair of casters 24 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com