Automatic chucking device

A card-loading and automatic technology, applied in hand-held tools, manufacturing tools, etc., can solve the problems of slow speed, accidental injury, low efficiency, etc., and achieve the effect of saving manpower and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the objectives, technical solutions and advantages of the present invention clearer, the following further describes the present invention in detail with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention.

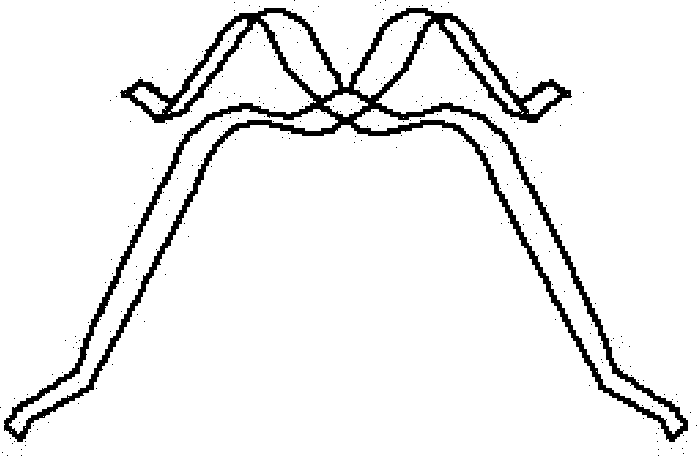

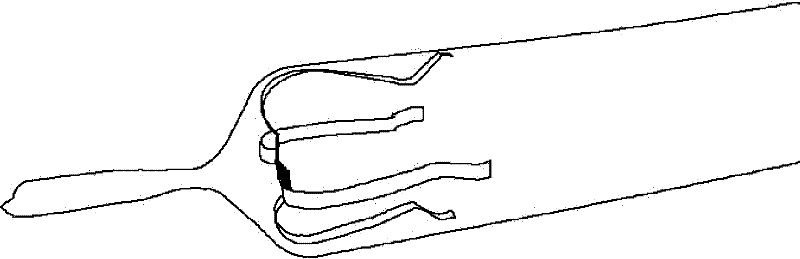

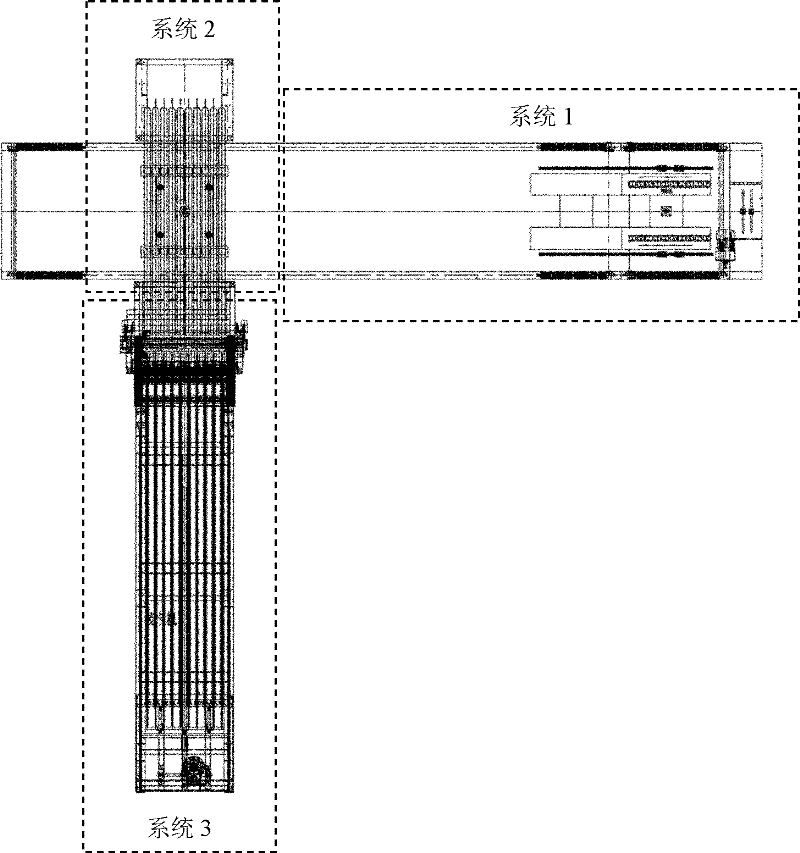

[0041] The present invention provides an automatic card loading equipment. The equipment includes three parts, which are the step transfer system 1, the transmission positioning system 2 and the automatic card loading system 3. Among them, the step transfer system 1 is used for The vacuum tube is delivered to the transfer positioning system 2. The transfer positioning system 2 is used to transfer the transferred vacuum tube to the designated position to be loaded, and the automatic card filling system 3 is used to fill the card into the card loader first, and then Then transfer the card in the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap