Production method of bamboo floor with wood line strips, annual ring lines, branch scar lines and colours on upper surface

A technology for flooring and annual rings, which is used in the joining of wooden veneers, wood processing appliances, manufacturing tools, etc., can solve the problems of easy slippage, damage, and single color, and achieve the effect of three-dimensional and non-slippery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

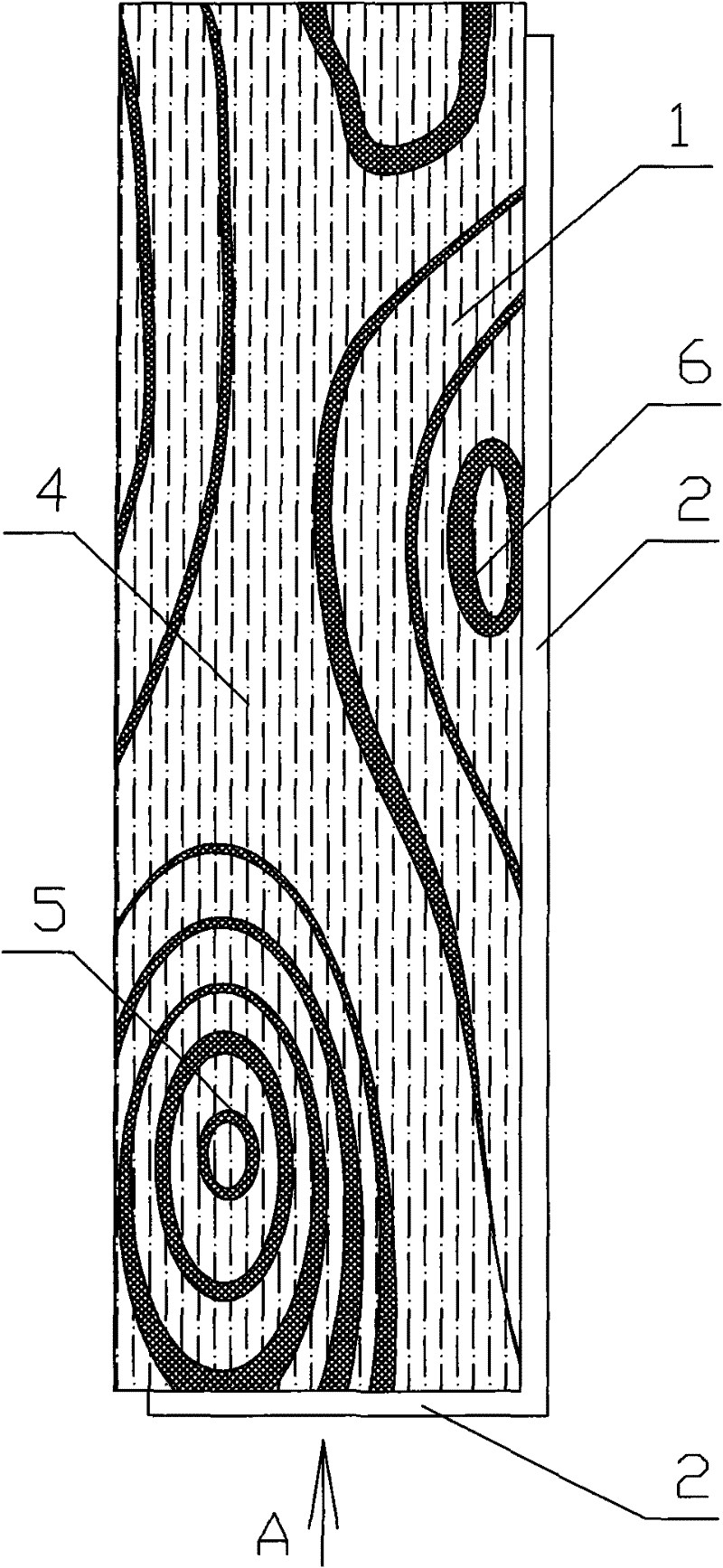

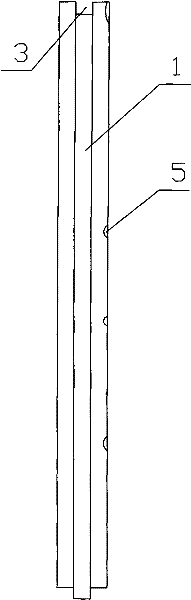

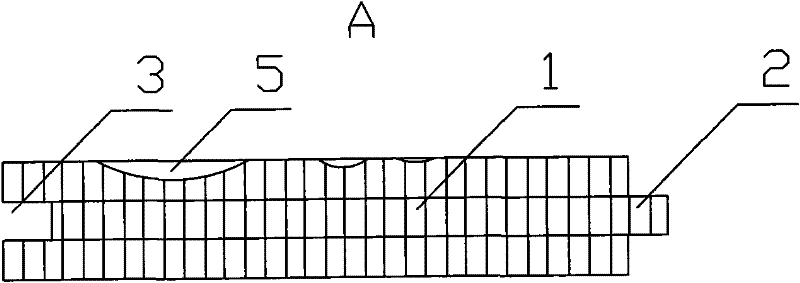

[0022] figure 1 , figure 2 , image 3 Shown according to the upper surface of the present invention has wood line stripes, annual ring pattern, branch scar pattern and the color of the bamboo floor of the manufacturing method of the floor made, according to the following steps:

[0023] 1. Blank slab preparation: The plates formed by bamboo slices are vertically erected and flattened to make a floor slab with a rectangular cross-section, and there are adhesives between bamboo slices and between bamboo strips;

[0024] ②Press the annual ring pattern 5 and the branch scar pattern 6: Roll the steel roller with the wood annual ring pattern and the branch scar pattern protrusion on the upper surface of the floor slab to form the grooved annual ring pattern 5 and the branch scar pattern 6 ;

[0025] ③Process tenons and mortises: process mortises 2 or mortises 3 on both sides and both ends of the floor slab to become floor semi-finished products 1;

[0026] 4. Spray paint: spray...

no. 2 example

[0033] figure 1 , figure 2 , Figure 4 Shown according to the upper surface of the present invention has wood line stripes, annual ring pattern, branch scar pattern and the color of the bamboo floor of the manufacturing method of the floor made, according to the following steps:

[0034] ①Bamboo slab preparation: Lay bamboo slices vertically and stack them to form a floor slab with a rectangular cross section, with adhesive between bamboo slices and between bamboo strips;

[0035] ②Press the annual ring pattern 5 and the branch scar pattern 6: Roll the steel roller with the wood annual ring pattern and the branch scar pattern protrusion on the upper surface of the floor slab to form the grooved annual ring pattern 5 and the branch scar pattern 6 ;

[0036] ③Process tenons and mortises: process mortises 2 or mortises 3 on both sides and both ends of the floor slab to become floor semi-finished products 1;

[0037] 4. Spray paint: spray the primer of wood color on the upper...

no. 3 example

[0044] figure 1 , figure 2 , Figure 5 Shown according to the upper surface of the present invention has wood line stripes, annual ring pattern, branch scar pattern and the color of the bamboo floor of the manufacturing method of the floor made, according to the following steps:

[0045] ①Slab preparation: the bamboo strips are formed into longitudinally integrated plates to make a floor blank with a rectangular cross-section, and there are adhesives between the bamboo strips and between the bamboo strips;

[0046] ②Press the annual ring pattern 5 and the branch scar pattern 6: Roll the steel roller with the wood annual ring pattern and the branch scar pattern protrusion on the upper surface of the floor slab to form the grooved annual ring pattern 5 and the branch scar pattern 6 ;

[0047] ③Process tenons and mortises: process mortises 2 or mortises 3 on both sides and both ends of the floor slab to become floor semi-finished products 1;

[0048] 4. Spray paint: spray th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com