Machine for forming groove in place on stone material

A slotting machine and stone technology, applied in stone processing tools, stone processing equipment, work accessories, etc., can solve the problems of low processing efficiency, low degree of automation, inaccuracy, etc., and achieve accurate slotting position, high degree of mechanization, Avoid positional imprecise effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

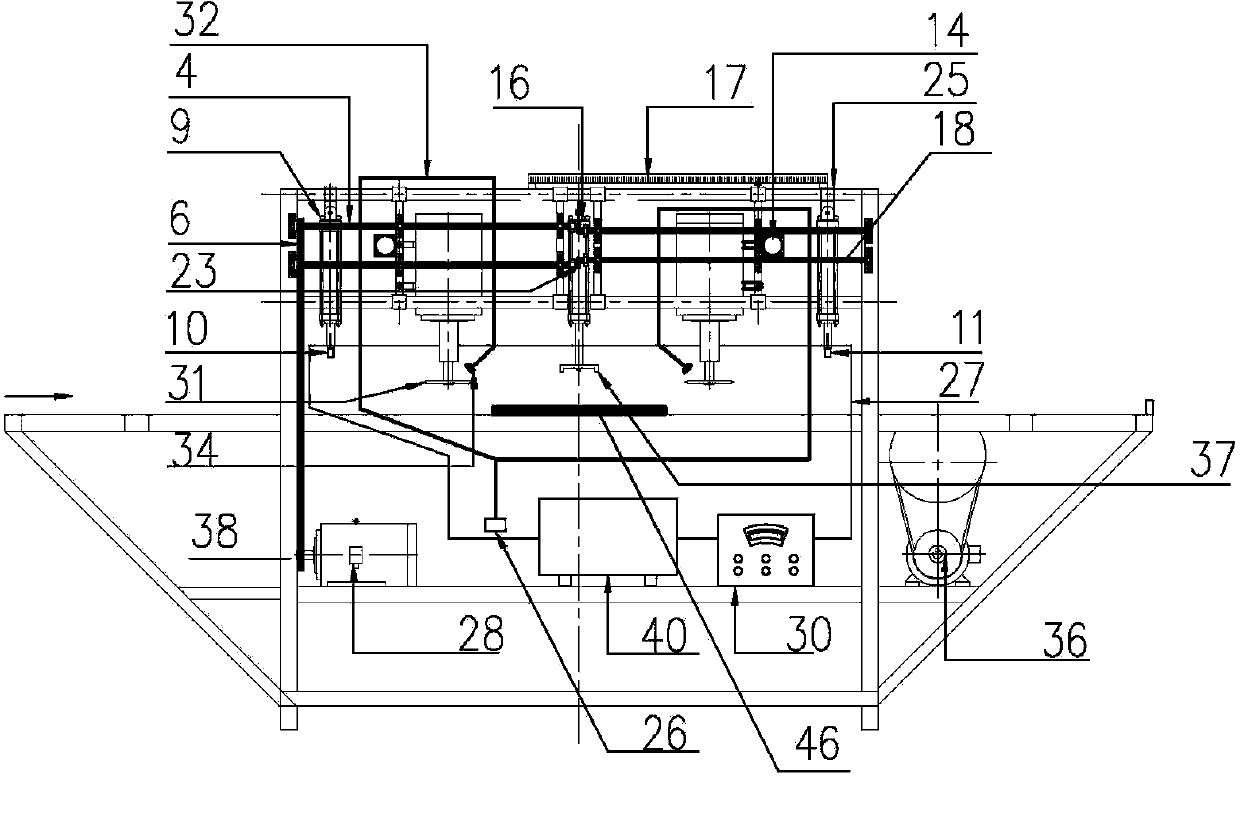

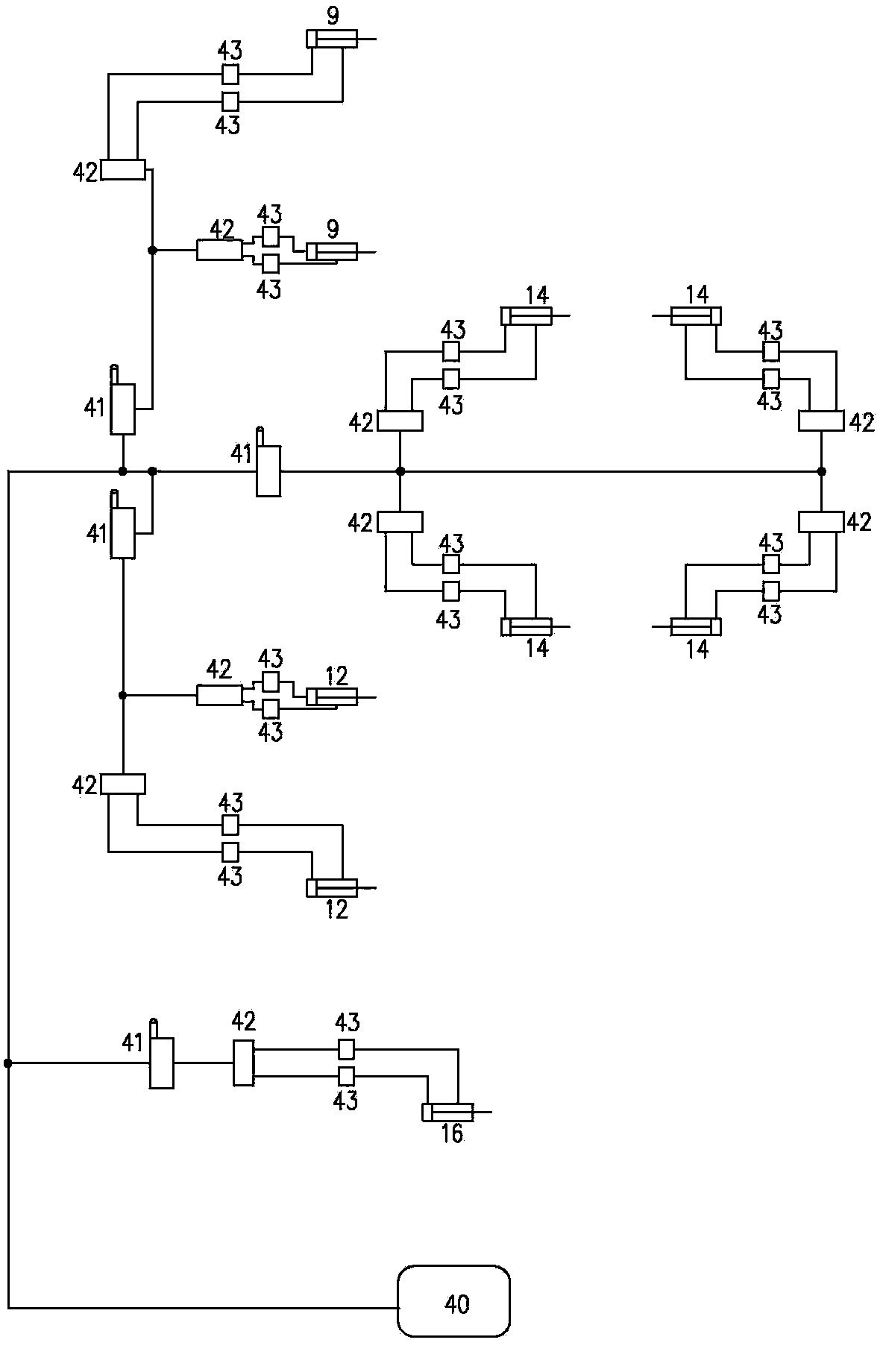

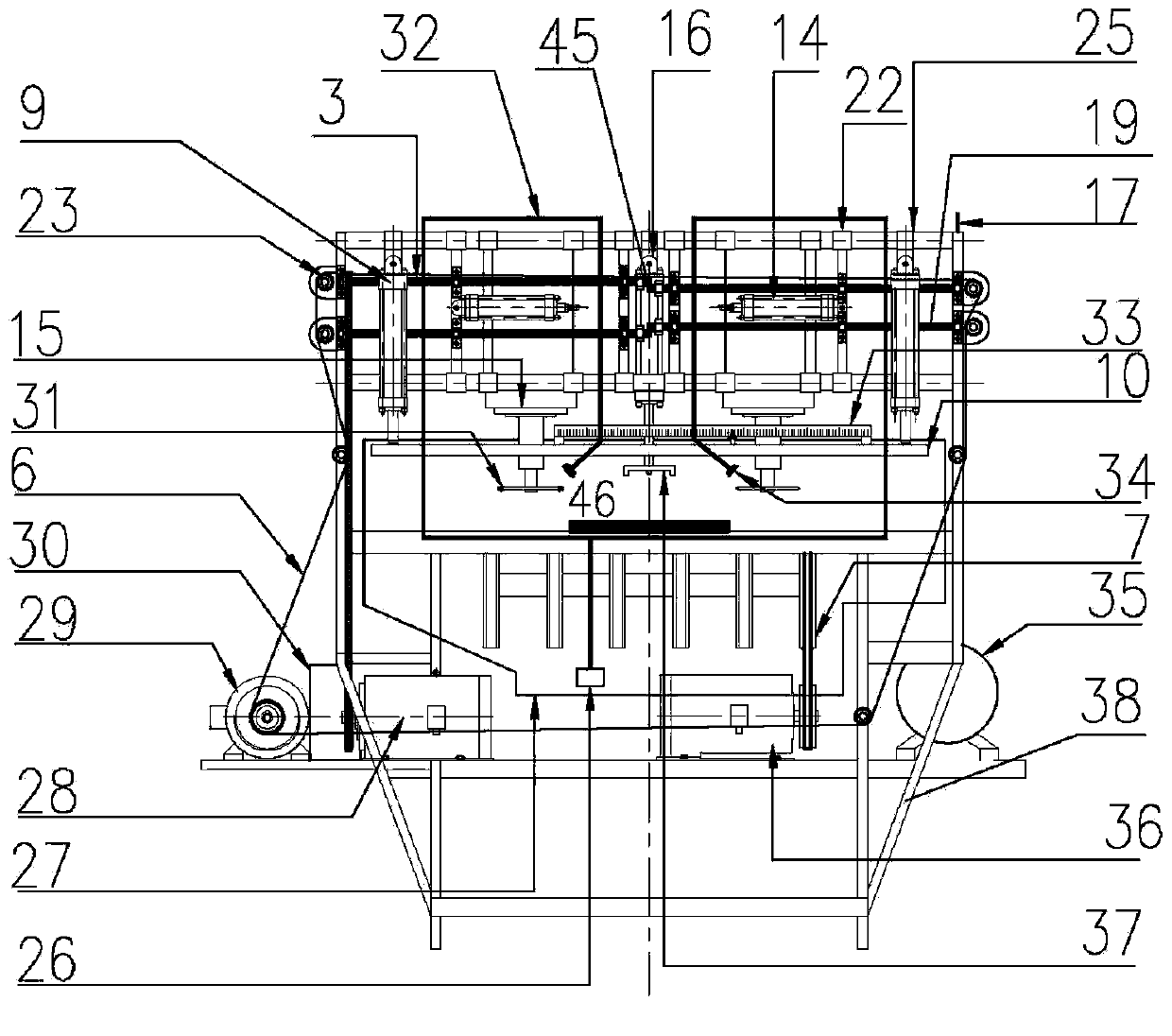

[0021] Such as figure 1 , figure 2 , image 3 As shown, the stone positioning and slotting machine of the present invention includes a frame 38, an electric control box 30 provided on the frame 38, a saw blade motor 15 and a cutting saw blade 31 connected to the saw blade motor 15. The stone positioning and slotting machine of the present invention is also provided with a stone conveying device 7, a pneumatic device, a saw blade cooling device, a groove spacing adjustment device, a groove depth adjustment device, a stone travel correction mechanism, a stone limit mechanism, a stone pressing mechanism and a button Box of 24. The button box 24 is installed at the front of the stone positioning slotting machine.

[0022] Such as figure 1 , figure 2 , image 3 As shown, the rack 38 is composed of a bottom rack, a middle rack, and an upper rack. The upper frame is connected to the left longitudinal beam 2 and the right longitudinal beam 201 by the two ends of the front cross beam 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com