Steel plate blank of rear lower inner skin of vehicle side body

An inner skin, automobile side technology, applied in the field of steel blanks, can solve the problems of many manufacturing methods, low utilization rate of materials, and many wastes, etc., and achieve the effects of improving accuracy and quality, saving costs and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

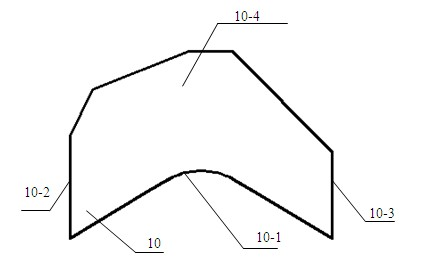

[0017] see figure 1 , the existing lower inner skin of the side wall of the automobile has an irregular polygonal shape when developed, the left and right sides are vertically parallel, the lower side is a circular arc, and the upper side is four continuously bent sides. The developed shape of the final product of the present invention is similar to it.

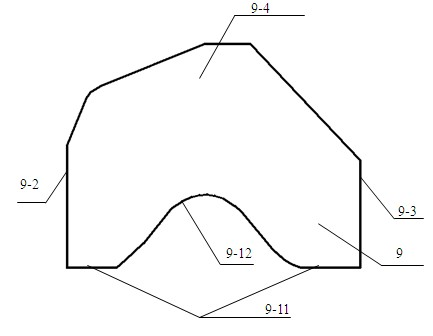

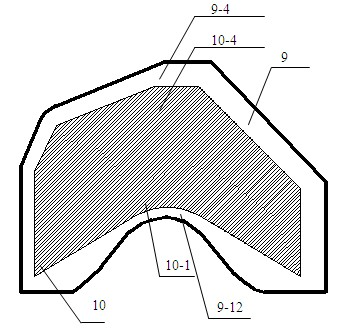

[0018] see figure 2 , image 3 A kind of steel plate blank of the rear lower inner skin of the car side wall shown, the two sides 9-11 of the bottom of its body are all straight, and the middle part 9-12 is a notch, and the notch 9-12 of the body is in line with the car. Corresponds to the notch 10-1 on the lower side of the rear lower inner skin development surface of the side wall; the left side 9-2 and right side 9-3 of the main body 9 are parallel to each other; the upper side of the main body 9 is a continuous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com