Super-fine sand blended fine aggregate for pump concrete

A technology for pumping concrete and ultra-fine sand, which is applied in the field of fine aggregates, can solve the problems of idle waste of ultra-fine sand resources and the inability of ultra-fine sand to be widely used, achieve significant economic and ecological benefits, reduce over-reliance and excessive The effect of mining and protecting the ecological environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

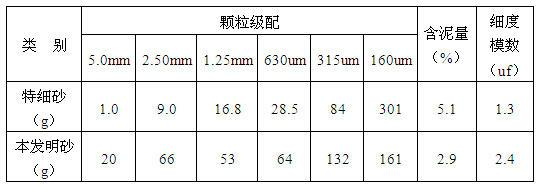

[0014] Mix 133 parts of ultra-fine sand, 5 parts of machine-made sand, and 149 parts of natural medium sand. The limestone content of the limestone machine-made sand is 6%, and the calcium carbonate content in the stone powder is 85%. The mixed fine aggregate was compared with the separate ultra-fine sand in terms of particle size distribution, mud content and porosity. The specific data are shown in Table 1.

[0015] Table 1

[0016]

[0017] As can be seen from Table 1, the fine aggregate of the present invention has improved the particle gradation and mud content of the individual extra-fine sand, so that the particle gradation of the fine aggregate is more in line with the requirements of pumped concrete, and at the same time the original mud content exceeds the standard. The mud content of ultra-fine sand complies with the relevant provisions of JGJ52-2006 "Standards for the Quality and Inspection Methods of Sand and Stone for Ordinary Concrete".

Embodiment 2

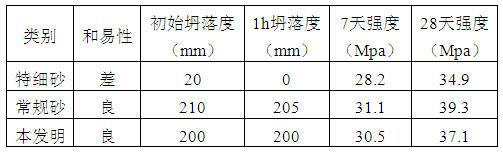

[0019] C30 pumped concrete was prepared using the fine aggregate of the present invention. The formula of C30 pumped concrete is: water: 167 kg / m 3 , cement (PO.42.5): 305 kg / m 3 , Fly ash (Class I): 50 kg / m 3 , sand: 777 kg / m 3 , gravel (5~31.5mm): 1037 kg / m 3 , admixture GL-2S: 5.33 kg / m 3 . Put each raw material component into a forced mixer according to the required parts by weight and stir for 180 seconds to obtain C30 pumped concrete.

[0020] The "sand" item in the above formula uses the fine aggregate of the present invention, separate ultra-fine sand and conventional concrete sand (ie, medium-coarse natural sand), and the performance comparison of the prepared C30 concrete is shown in Table 2. Show. Wherein the formula of the fine aggregate of the present invention is: 133 parts of extra fine sand, 5 parts of machine-made sand, 149 parts of sand in natural sand. The limestone content of the limestone machine-made sand is 6%, and the calcium carbonate content i...

Embodiment 3

[0025] C20 pumped concrete was prepared using the fine aggregate of the present invention. The formula of C20 pumped concrete is: water: 167 kg / m 3 , cement (PO.42.5): 238 kg / m 3 , Fly ash (Class I): 45 kg / m 3 , Sand: 896 kg / m 3 , gravel (5~31.5mm): 979 kg / m 3 , Admixture GL-2S: 3.68 kg / m 3 . Put each raw material component into a forced mixer according to the required parts by weight and stir for 180 seconds to obtain C20 pumped concrete.

[0026] For the "sand" item in the above formula, the fine aggregate of the present invention and conventional concrete sand (ie, medium-coarse natural sand) are used respectively, and the cost price comparison of the prepared C20 concrete is shown in Table 3. Wherein the formula of the fine aggregate of the present invention is: 192 parts of extra fine sand, 6 parts of machine-made sand, 135 parts of sand in natural sand. The limestone content of the limestone machine-made sand is 9%, and the calcium carbonate content in the stone p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com