Phosphorus-containing phenolic resin, resin composition and cured product

A technology of phenolic resin and its meaning, applied in the field of phosphorus-containing phenolic resin and curable resin composition, can solve the problem of low adhesiveness, poor adhesiveness and heat-resistant reliability of epoxy resin cured products, and difficult to remove completely. Solvent and other problems, to achieve the effect of good compatibility and excellent flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

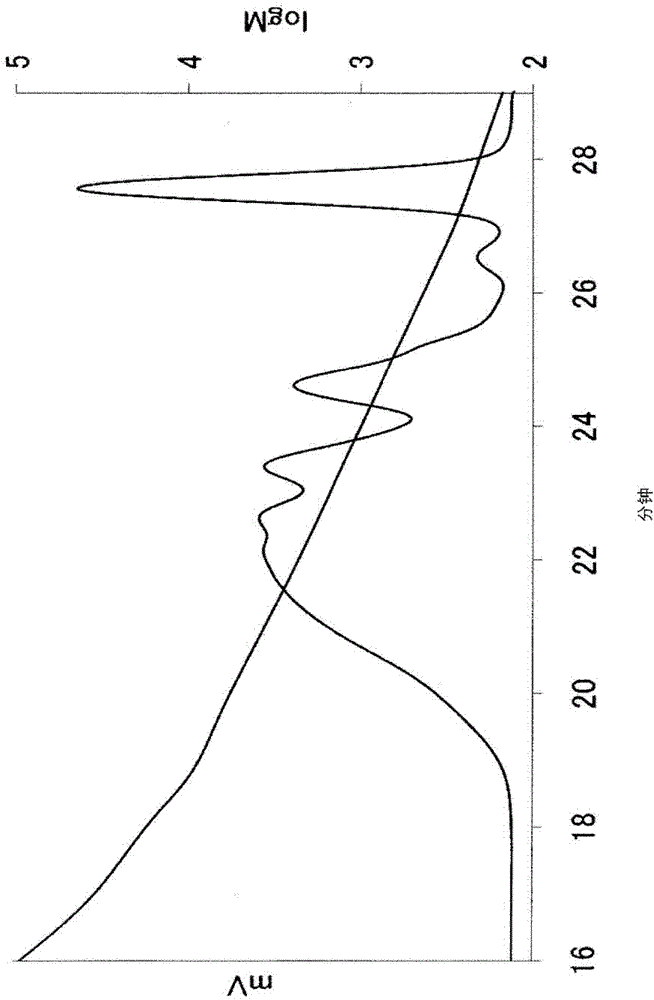

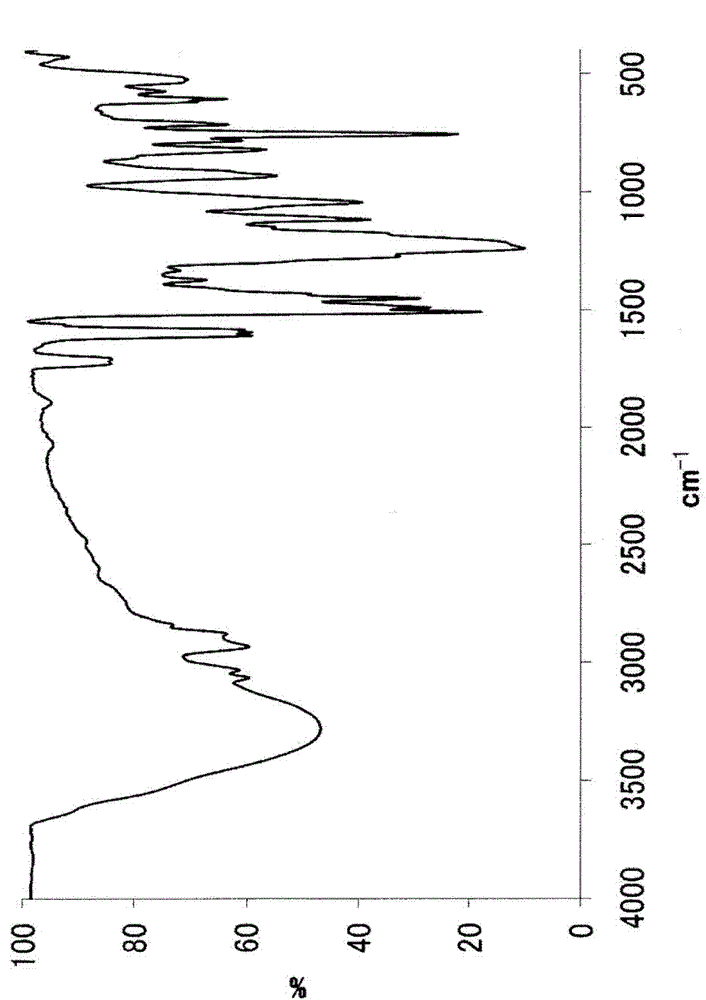

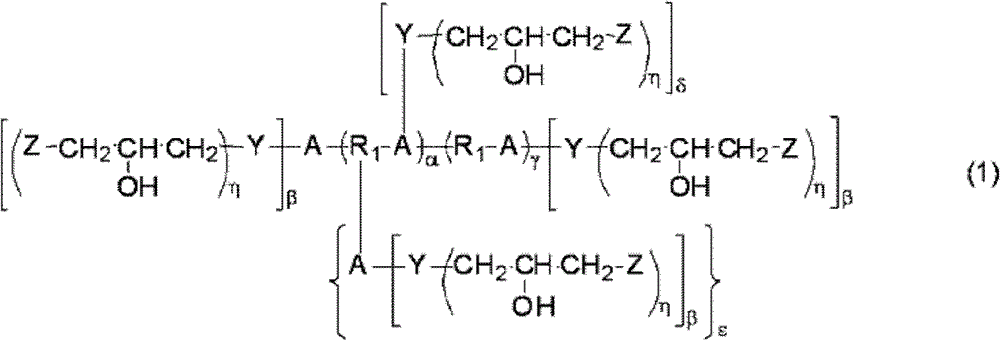

Embodiment 1

[0086] Bisphenol F type epoxy resin (Nippon Steel Chemical Co., Ltd. product name YDF-170, epoxy equivalent 170g / eq.) 84.9 parts, drop into 10-(2,5-dihydroxyphenyl)-10H-9-oxa-10-phosphaphenanthrene-10-oxide (trade name HCA-HQ manufactured by Sanko Co., Ltd. , a melting point of 256° C., a phosphorus content of 9.6%, a hydroxyl equivalent of 162 g / eq.) 78.3 parts, a trishydroxyphenylmethane type novolak resin (trade name RESITOPTPM-100 manufactured by Qunei Chemical Industry Co., Ltd., a hydroxyl equivalent of 97.5 g / eq.) 50.4 parts and propylene glycol monomethyl ether acetate (PMA) 53 parts. At this time, the ratio of the phosphorus-containing phenolic compound in all phenolic compounds was 61%, and the functional group ratio of the epoxy resin to the phosphorus-containing phenolic compound and the phosphorus-free phenolic resin was 1.00:0.96:1.04. Triphenylphosphine was added thereto as a catalyst and reacted at 160° C. for 3 hours, and then diluted by adding a mixed solve...

Embodiment 2

[0088] It reacted by the method similar to Example 1 except having changed TPM-100 of Example 1 into 51.6 parts of bisphenol F (made by Honshu Chemical Industry Co., Ltd., hydroxyl equivalent: 100g / eq.). At this time, the ratio of the phosphorus-containing phenolic compound in all the phenolic compounds was 60%, and the functional group ratio of the epoxy resin, the phosphorus-containing phenolic compound and the phosphorus-free phenolic resin was 1.00:0.96:1.04. After the reaction, dilute with PGM / MEK mixed solvent. The obtained phosphorus-containing phenolic resin solution is light yellow and transparent, with a non-volatile component of 60%, a phosphorus content of 3.5%, a number average molecular weight of 1620, and a hydroxyl equivalent of 430g / eq. Table 1 shows the input amount, the input ratio, the properties of the resin, and the like.

Embodiment 3

[0090] Except that YDF-170 of embodiment 1 is changed to alkylene glycol type epoxy resin (Nippon Steel Chemical Co., Ltd. trial product name TX-0929, epoxy equivalent is 140g / eq.) 70.3 parts, pass and implement Example 1 reacted in the same way. At this time, the ratio of the phosphorus-containing phenolic compound in all the phenolic compounds was 58%, and the functional group ratio of the epoxy resin, the phosphorus-containing phenolic compound and the phosphorus-free phenolic resin was 1.00:0.92:1.08. After the reaction, dilute with PGM / MEK mixed solvent. The obtained phosphorus-containing phenolic resin solution is light yellow and transparent, with a non-volatile content of 60%, a phosphorus content of 3.6%, a number-average molecular weight of 1943, and a hydroxyl equivalent of 393g / eq. Table 1 shows the input amount, the input ratio, the properties of the resin, and the like.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com