Device and method for controlling basal heating in chemical gaseous phase sedimentary chamber

A chemical vapor deposition and chamber technology, applied in furnace control devices, gaseous chemical plating, lighting and heating equipment, etc., can solve the problem of increasing the DC power supply current, the power of the heater 11 drops too fast, and the temperature of the tray 13 exceeds the temperature Set value and other issues to achieve the effect of stabilizing the substrate temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0048] In the following description, many specific details are set forth in order to fully understand the present invention, but the present invention can also be implemented in other ways than those described here, so the present invention is not limited by the specific embodiments disclosed below.

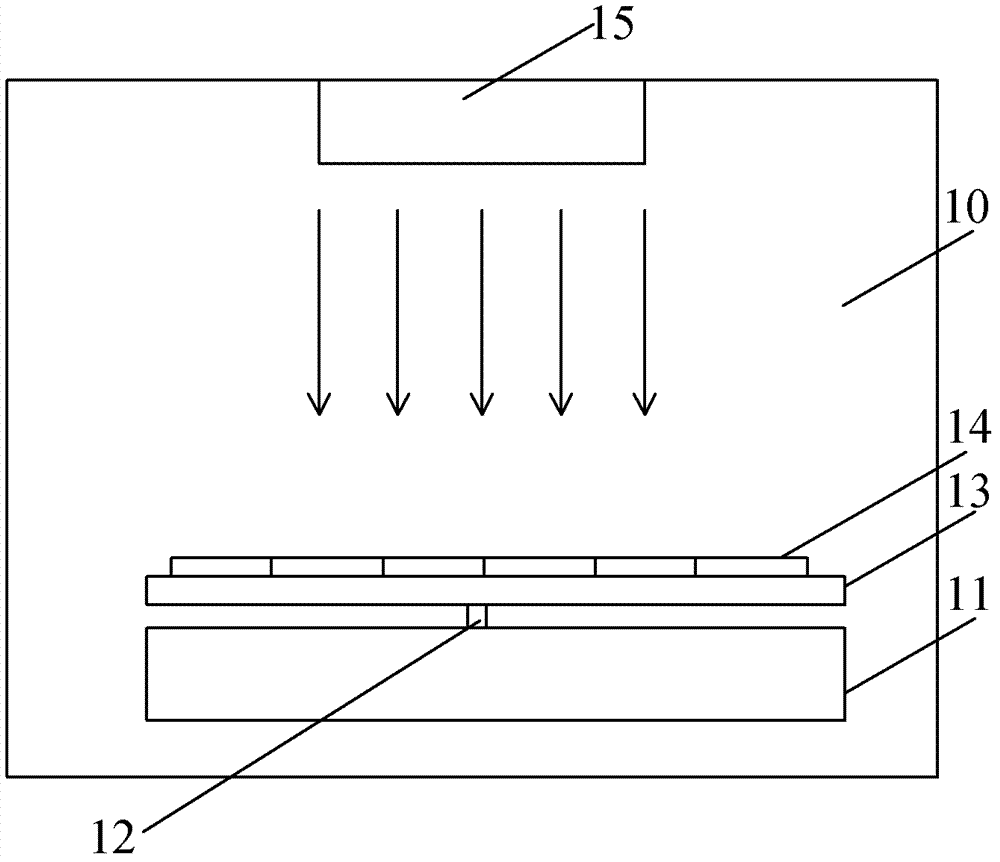

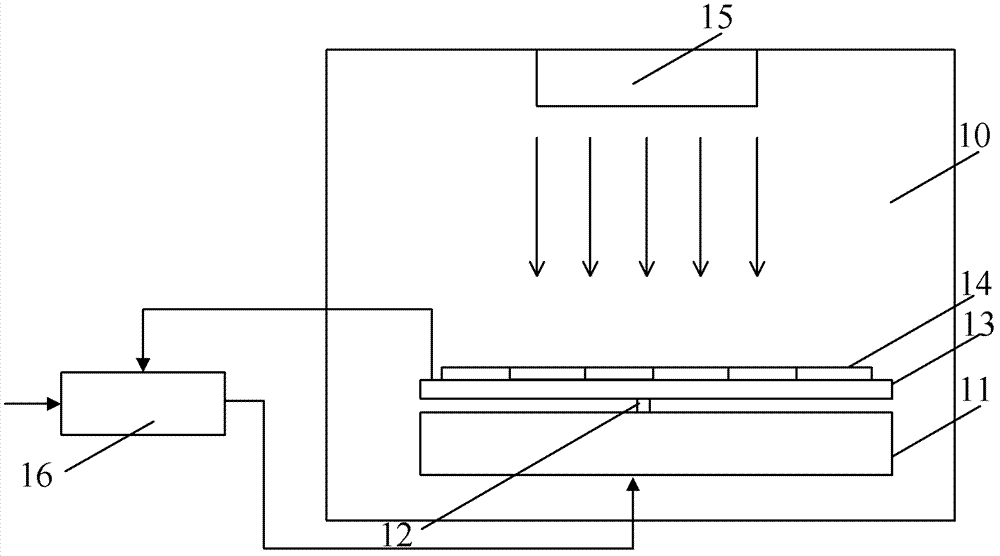

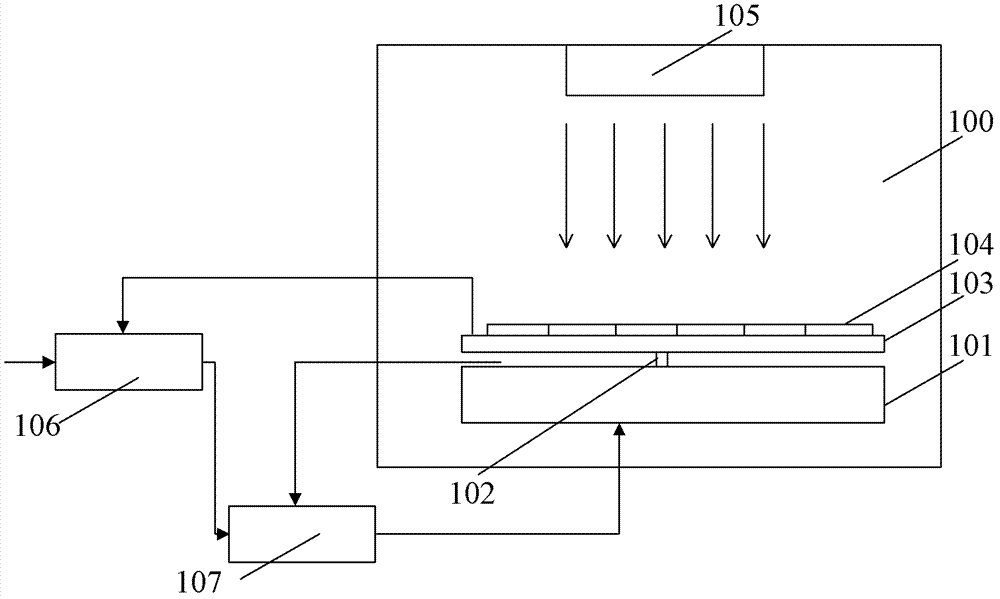

[0049] In order to solve the problems in the prior art, the present invention provides a device for controlling the heating of the substrate in the chemical vapor deposition chamber, referring to image 3 , shows a schematic diagram of an embodiment of an apparatus for controlling substrate heating in a chemical vapor deposition chamber of the present invention.

[0050] It should be noted that, the present invention is illustrated with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com