Straight-cylinder bottomless grid-type tobacco seedling raising device and method

The technology of a seedling raising device and a bottomless chamber is applied to the tobacco seedling raising device and the field of raising seedlings in a straight-tube bottomless chamber, and can solve the problems such as poor extension of fibrous roots and secondary lateral roots, not high enough temperature stability for seedlings, and unfavorable growth and development of tobacco seedlings. , to reduce the proportion of dead seedlings, improve the survival rate of transplanting, and reduce the time of returning seedlings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

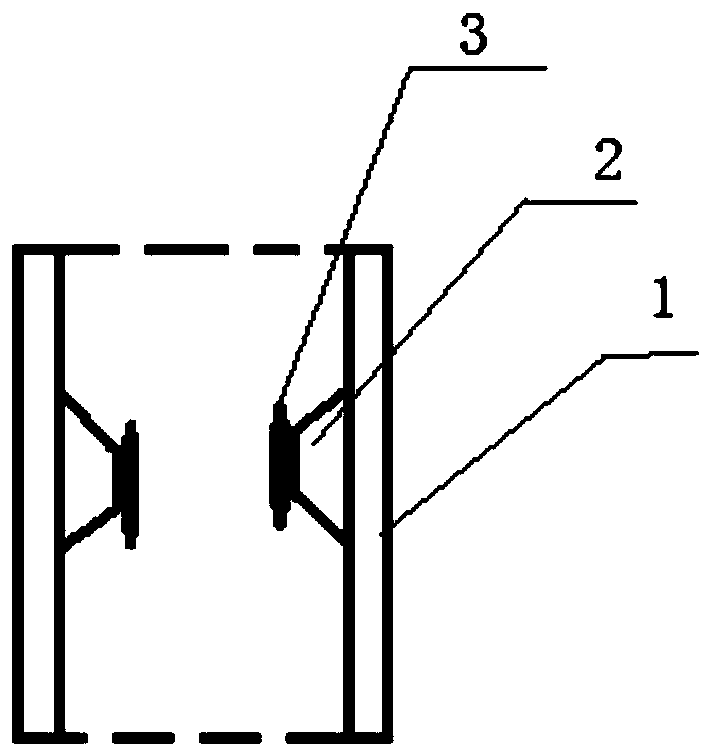

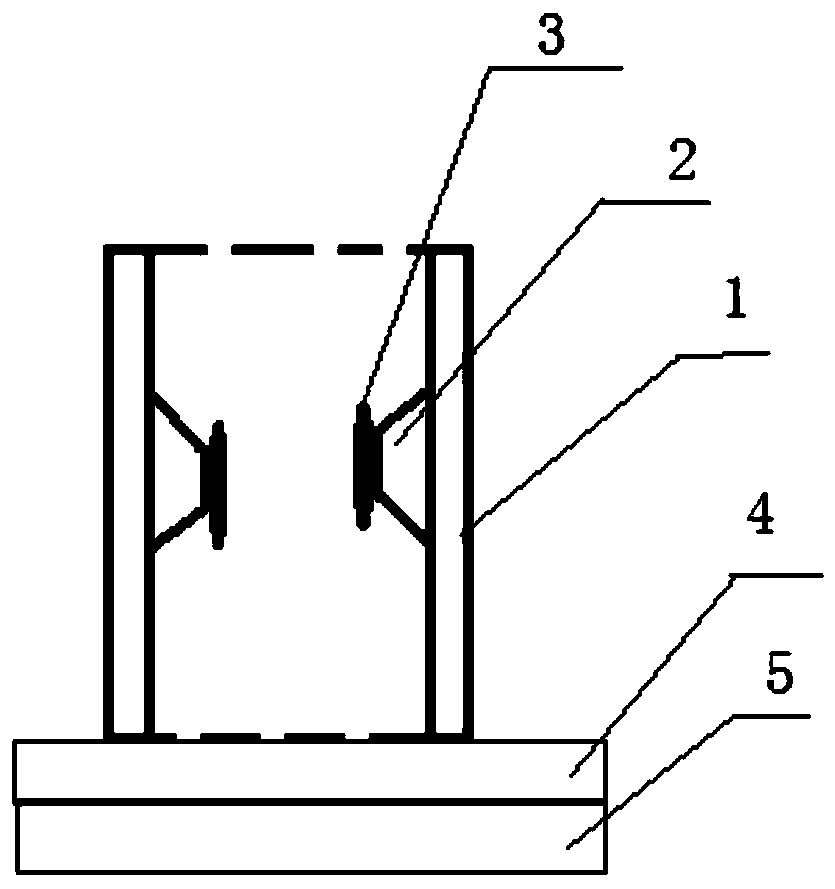

[0044] Such as figure 1 Among them, the tobacco seedling device includes a hollow straight cylinder 1, and an annular protrusion 2 is arranged on the inner wall 1 of the straight cylinder. Preferably, a sponge body 3 is arranged on the outer wall of the annular protrusion 2, and the annular protrusion 2 can be inserted into the straight cylinder. The soil in 1 forms two upper and lower layers. The first sponge body 3 makes the surface of the annular protrusion 2 have shrinkage characteristics, which makes it easy to take out the seedlings as a whole. After the upper layer is compacted, the lower layer is protected by the annular protrusion 2 and is not compressed, so the realization is loose. Yes, when the seedlings are to be taken, the soil and roots in the lower layer of the annular protrusion 2 are easy to take out. Such as figure 2 , the tobacco seedling device also includes soil and water conservation blanket 4, ceramic fiber blanket 5;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com