Leather/thick material embroidery machine

A technology for embroidery machines and thick materials, which is applied in the field of embroidery machines for sewing and embroidering leather and thick materials. It can solve the problems of no suitable thread trimming device and clamping device, complex structure, and movement of sewing materials. The effect of precise and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

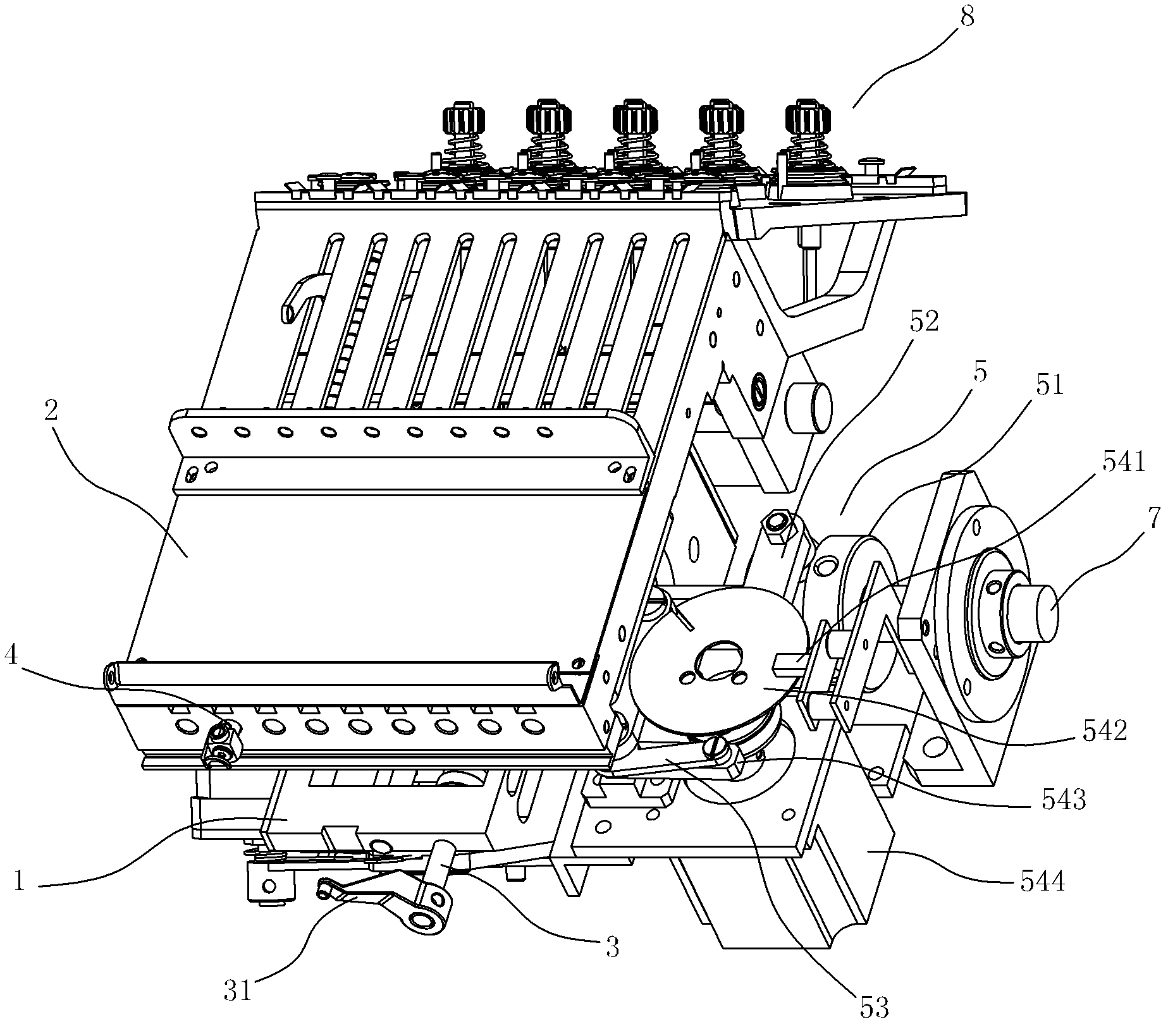

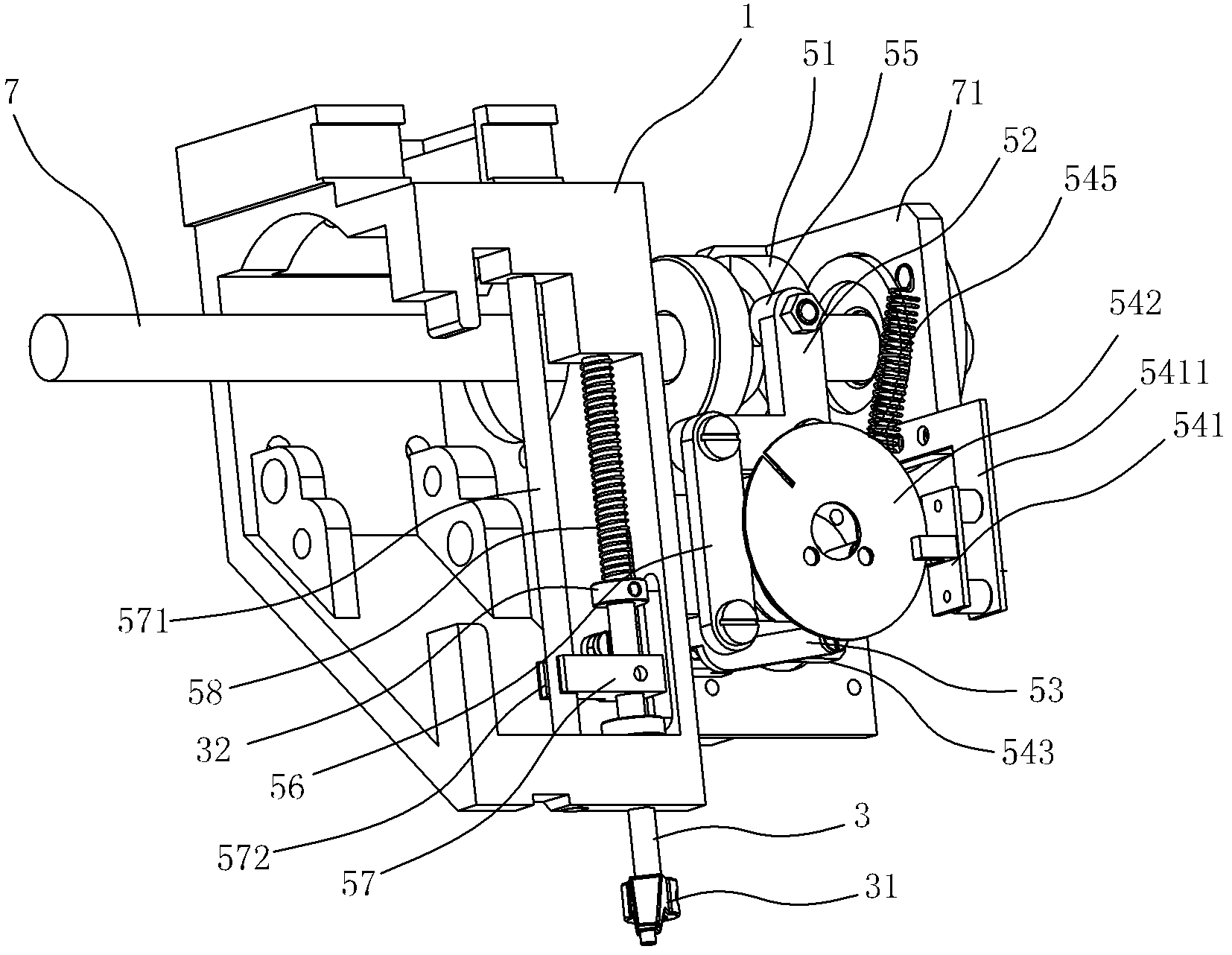

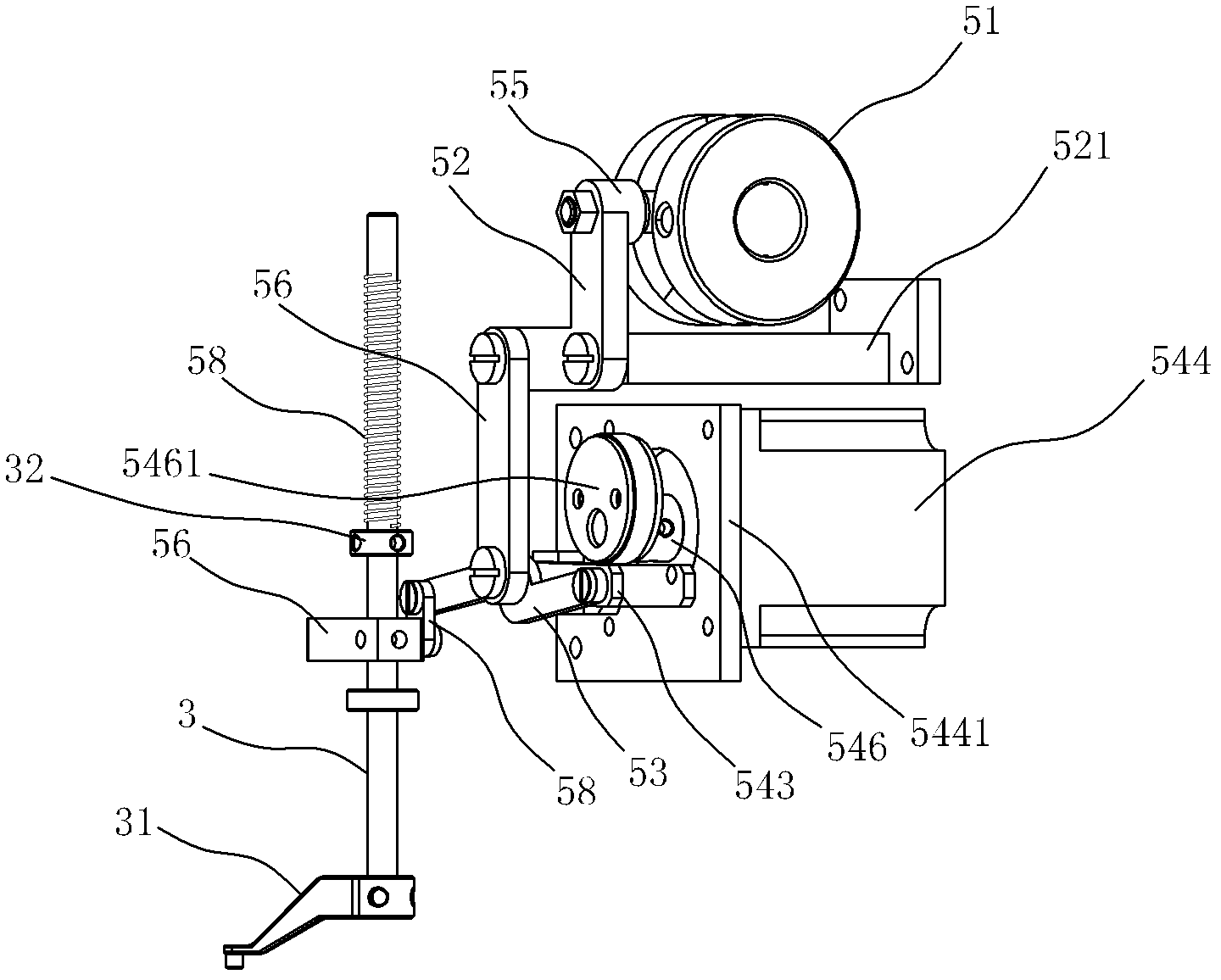

[0030] refer to Figure 1 to Figure 4 Shown, a kind of leather, thick material embroidery machine, comprise frame (not shown in the figure), the machine head 1 that is arranged on the frame, the upper shaft 7 that is arranged on the frame 1 laterally by upper shaft seat 71, The needle bar case 2 arranged on the machine head 1 movable laterally, several needle bars 4 arranged on the needle bar case 2 movable up and down, and connected to drive the needle bar case 2 to move laterally to select a needle bar 4 to work. The color drive mechanism (not shown in the figure), the needle bar drive mechanism (not shown in the figure) that is connected to drive the selected needle bar 4 to move up and down, the presser foot bar 3 that can move up and down on the machine head 1, the connection The presser foot driving mechanism 5 that drives the presser foot bar 3 to move up and down, and the thread trimmer 9 and thread clamping device 8 suitable for thick threads, the lower end of the nee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com